During the coronavirus outbreak, wellness often took center stage in discussions about long-term infection control strategies.

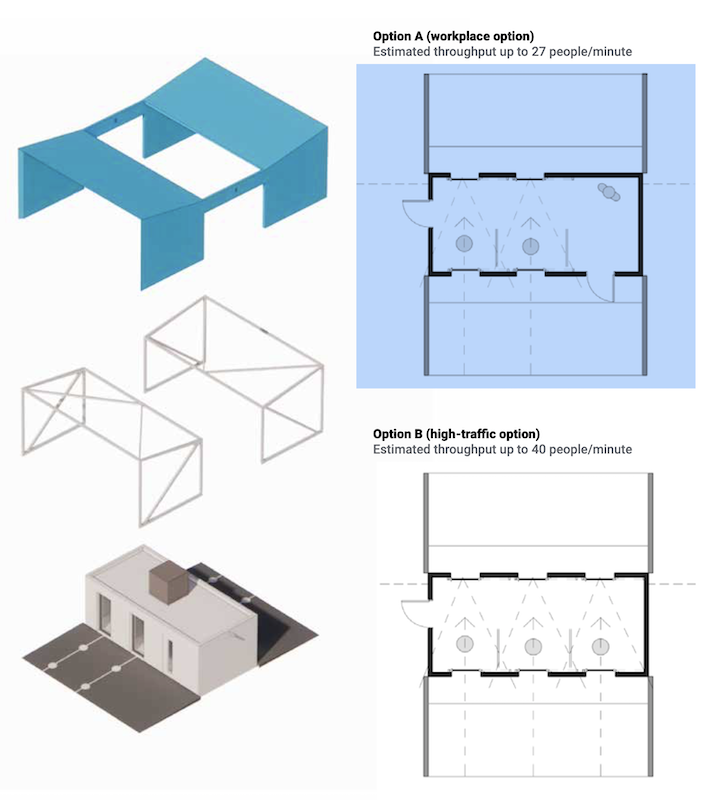

Leo A Daly and Turner Construction have partnered on the development of a design-build concept called WorkWell™, an assembly of prefabricated components designed to allow employers, schools, venues, airports and public spaces to efficiently screen large groups of entrants for signs of infectious disease.

The WorkWell™ modular point of entry offers a safe and welcoming setting for health screening of individuals entering high-traffic buildings and public spaces. The centerpiece is the entry pavilion, installed in any area where a controlled checkpoint is needed. Individuals are quickly checked for fever and potentially screened for other health risk factors. The pavilion is designed for touchless operation and includes air handling systems capable of controlling the transfer of airborne pathogens.

“It’s important for that health screening be a pleasant and welcoming experience,” says Daniel Yudchitz, AIA, Senior Design Architect with Leo A Daly. “We designed WorkWell™ to be an enhancement to a facility, not an ordeal. It should inspire confidence in the health and safety of everyone entering.”

WorkWell's modular design is adjustable for different locations and levels of anticipated screening capacity.

PREFABRICATION SPEEDS INSTALLATION PROCESS

WorkWell™ modules are fabricated in an automated shop environment for speed of implementation, product quality and contractor safety. Design-build delivery enables the units to be deployed rapidly at a competitive price point. Offsite fabrication and plug-and-play design require minimal need for onsite construction crews.

“Prefabrication and modularization allow us to meet aggressive schedules while maintaining a high level of quality control and minimizing the potential for on-site safety incidents,” says Brian Knowles, LEED AP, DBIA, industrial executive at Turner Construction. “By deploying rapidly and at scale, we can keep workforces and the public healthy and facilities safely operational.”

The marketing campaign for WorkWell launched last Thursday. The product doesn’t have a specific client yet, but the development team is in discussions with several prospects.

The cost of each installation will depend on the application, options chosen, and features chosen. Knowles tells BD+C that, the expected range is from $260,000 to $320,000. “We are looking at six-to-nine weeks for full occupancy from date of confirmed order/scope.”

Related Stories

Coronavirus | May 22, 2020

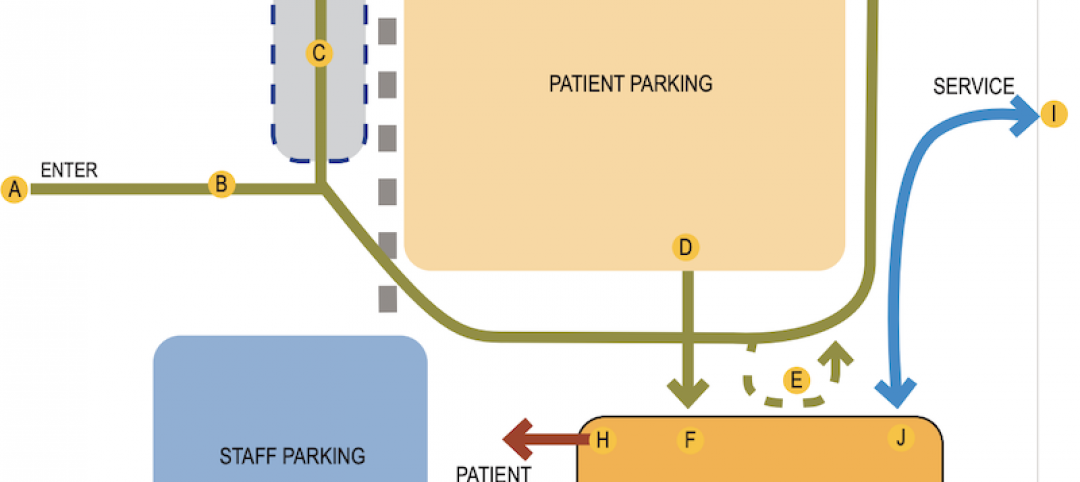

Designing a health facility for the next pandemic

Planning with intent is the key to readiness, states Eppstein Uhen Architects, the guide’s author.

Coronavirus | May 22, 2020

COVID-19: Healthcare designers look to the future of medical facilities in light of coronavirus pandemic

The American College of Healthcare Architects (ACHA) has released the key findings of a survey of its members revealing their insights on the future of healthcare architecture and the role of design in the context of the COVID-19 healthcare crisis.

Coronavirus | May 18, 2020

Will empty hotels provide an answer for affordable housing shortage?

A Los Angeles-based startup sees the Midwest as most fertile for adaptive reuse.

Coronavirus | May 18, 2020

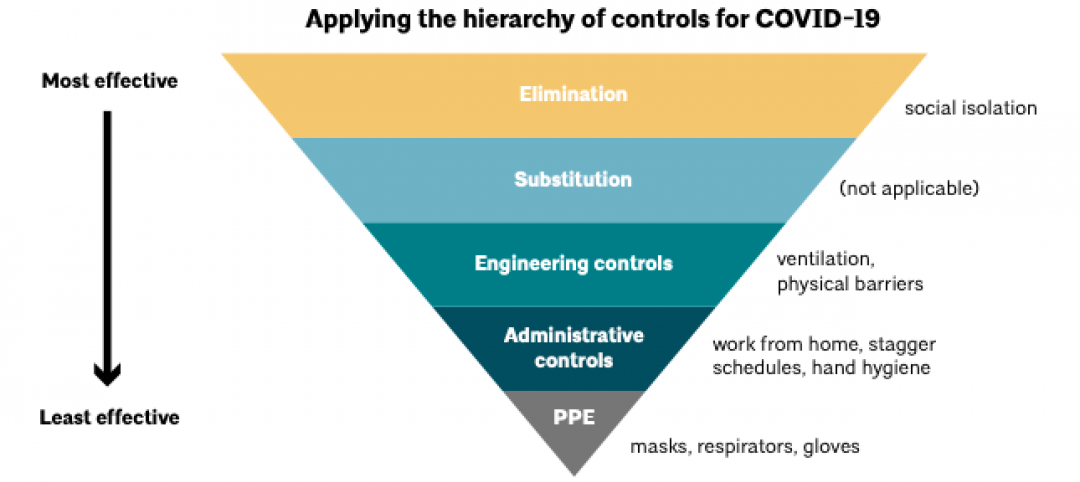

Infection control in office buildings: Preparing for re-occupancy amid the coronavirus

Making workplaces safer will require behavioral resolve nudged by design.

Coronavirus | May 18, 2020

Global design firms collaborate on new COVID-19 mobile testing lab to bring testing to vulnerable communities worldwide

Perkins and Will, Schmidt Hammer Lassen Architects, and Arup Group develop scalable solutions for increased testing capacity within high-density and under-served neighborhoods.

Coronavirus | May 11, 2020

Experts offer a 13-point plan to reduce coronavirus deaths in nursing homes

Two nationally recognized experts in the design of senior living facilities offer a 13-point plan to protect our frailest citizens.

Glass and Glazing | May 8, 2020

Vitro Architectural Glass releases guide on decontaminating glass surfaces

The five-page technical document offers methods for cleaning and sanitizing glass surfaces.

Coronavirus | May 7, 2020

White paper clarifies steps, roles for use of metal composite material

Responsibilities of manufacturers, distributors, and fabricators outlined.

Coronavirus | May 7, 2020

Architects release new resource for safer re-occupancy of buildings

The American Institute of Architects (AIA) is releasing a new Re-occupancy Assessment Tool today that provides strategies for limiting exposure to COVID-19 in buildings.

Coronavirus | May 6, 2020

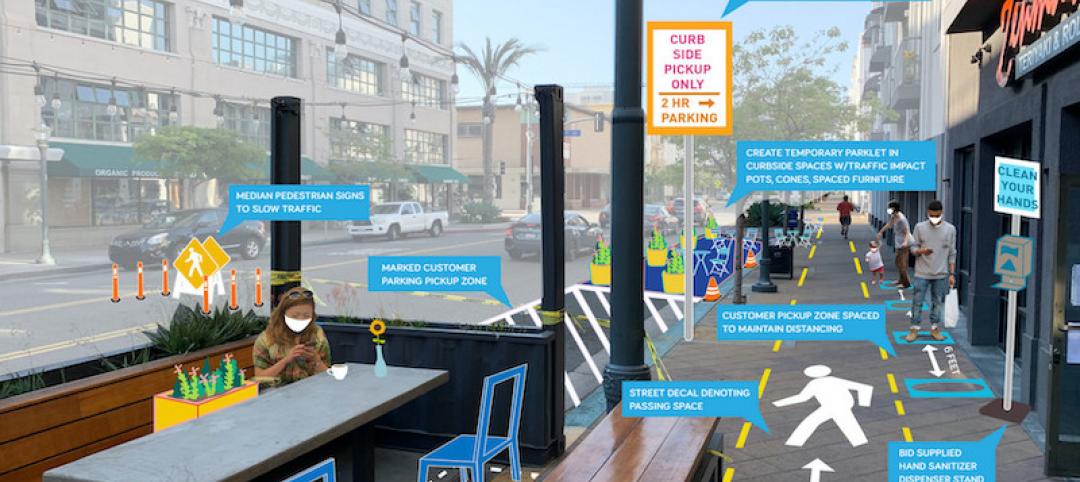

Reopening Main Street post-COVID-19 quarantine

Cities and communities will need to adjust public space to allow customers back in with distancing in mind.