During the coronavirus outbreak, wellness often took center stage in discussions about long-term infection control strategies.

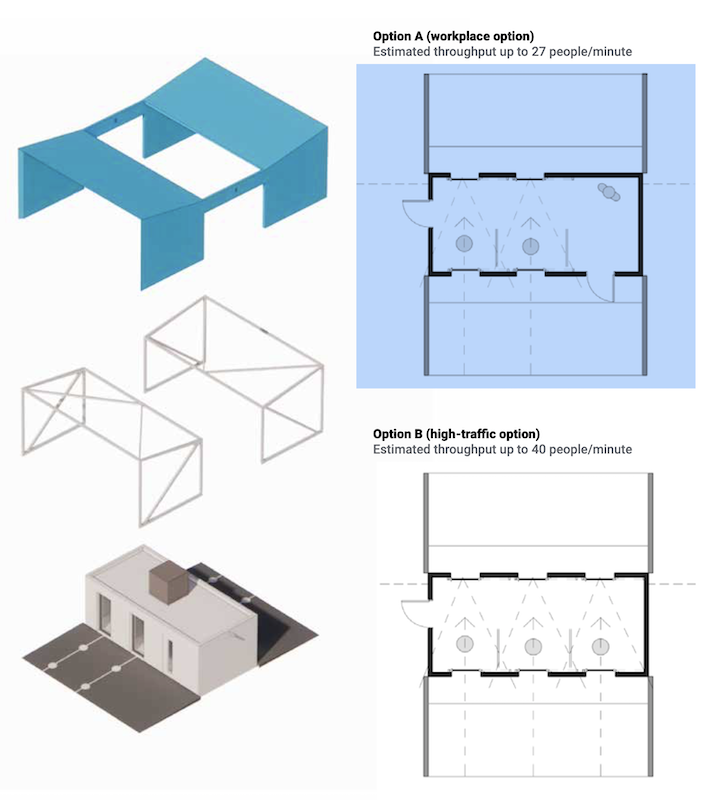

Leo A Daly and Turner Construction have partnered on the development of a design-build concept called WorkWell™, an assembly of prefabricated components designed to allow employers, schools, venues, airports and public spaces to efficiently screen large groups of entrants for signs of infectious disease.

The WorkWell™ modular point of entry offers a safe and welcoming setting for health screening of individuals entering high-traffic buildings and public spaces. The centerpiece is the entry pavilion, installed in any area where a controlled checkpoint is needed. Individuals are quickly checked for fever and potentially screened for other health risk factors. The pavilion is designed for touchless operation and includes air handling systems capable of controlling the transfer of airborne pathogens.

“It’s important for that health screening be a pleasant and welcoming experience,” says Daniel Yudchitz, AIA, Senior Design Architect with Leo A Daly. “We designed WorkWell™ to be an enhancement to a facility, not an ordeal. It should inspire confidence in the health and safety of everyone entering.”

WorkWell's modular design is adjustable for different locations and levels of anticipated screening capacity.

PREFABRICATION SPEEDS INSTALLATION PROCESS

WorkWell™ modules are fabricated in an automated shop environment for speed of implementation, product quality and contractor safety. Design-build delivery enables the units to be deployed rapidly at a competitive price point. Offsite fabrication and plug-and-play design require minimal need for onsite construction crews.

“Prefabrication and modularization allow us to meet aggressive schedules while maintaining a high level of quality control and minimizing the potential for on-site safety incidents,” says Brian Knowles, LEED AP, DBIA, industrial executive at Turner Construction. “By deploying rapidly and at scale, we can keep workforces and the public healthy and facilities safely operational.”

The marketing campaign for WorkWell launched last Thursday. The product doesn’t have a specific client yet, but the development team is in discussions with several prospects.

The cost of each installation will depend on the application, options chosen, and features chosen. Knowles tells BD+C that, the expected range is from $260,000 to $320,000. “We are looking at six-to-nine weeks for full occupancy from date of confirmed order/scope.”

Related Stories

Coronavirus | Apr 8, 2020

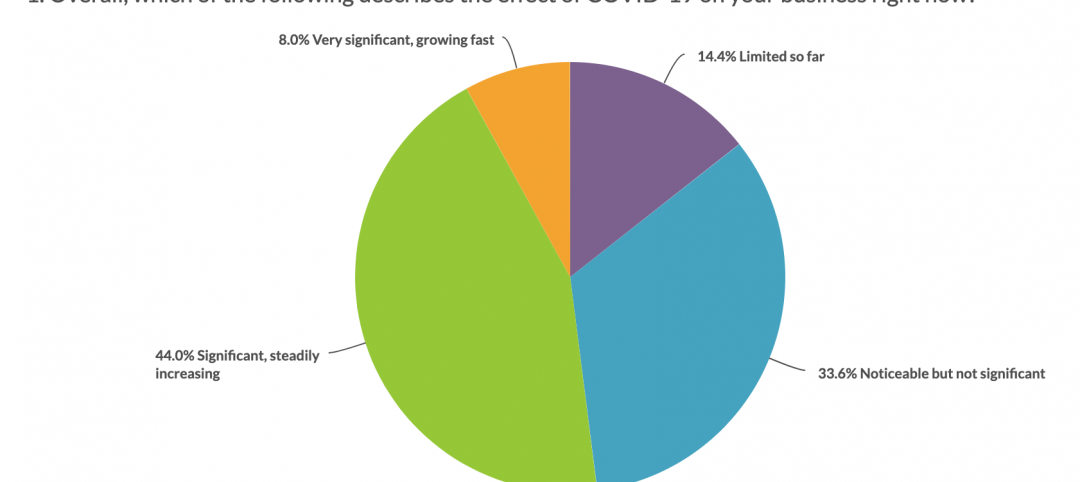

COVID-19 alert: Most U.S. roofing contractors hit by coronavirus, says NRCA

NRCA survey shows 52% of roofing contractor said COVID-19 pandemic was having a significant or very significant impact on their businesses.

Coronavirus | Apr 8, 2020

Navigate supply chain and manufacturing challenges during disruption

First, most important and most complex: Create an extensive safety plan for your facilities and job sites that protects both the personnel onsite and the end users of your product.

Coronavirus | Apr 7, 2020

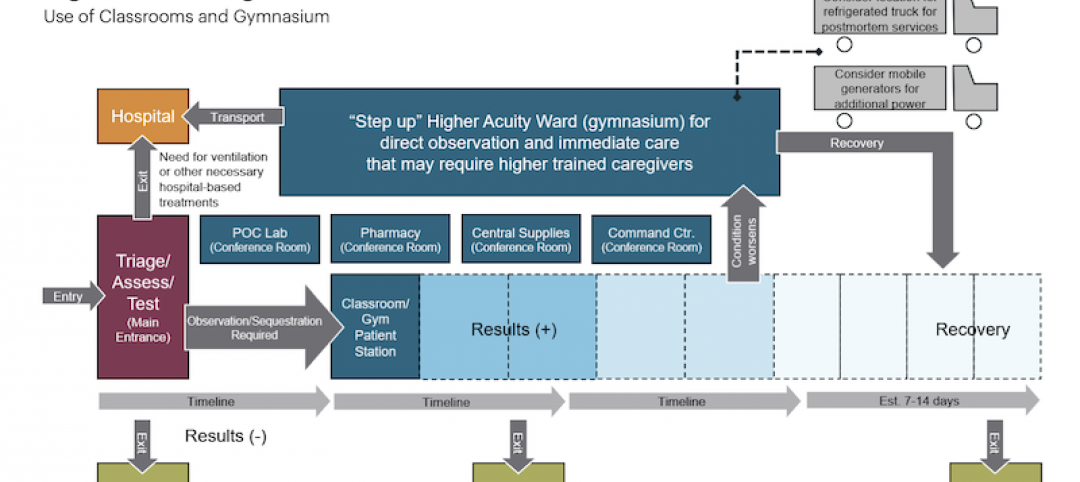

How to turn a high school into a patient care center in 15 days

HKS’s concept paper presents three scenarios.

Coronavirus | Apr 7, 2020

New Trump administration guidance now allows firms with 500 of fewer employees to qualify for paycheck protection program loans

Associated General Contractors of America secures fix to loan qualifications after alerting administration officials to small business administration language that excluded many firms.

Coronavirus | Apr 6, 2020

New small business administration loan guidance appears to exclude many construction firms that employ fewer than 500 people

Construction officials urge agency to make clear that firms that employ 500 or fewer people to qualify for paycheck protection program loans, regardless of revenue.

Coronavirus | Apr 6, 2020

Pandemic preparedness: How hospitals can adapt buildings to address worst-case scenarios

A Canadian healthcare architect looks at how hospital staff can act now to modify facilities and contain a pandemic.

Coronavirus | Apr 5, 2020

COVID-19: Most multifamily contractors experiencing delays in projects due to coronavirus pandemic

The NMHC Construction Survey is intended to gauge the magnitude of the disruption caused by the COVID-19 outbreak on multifamily construction.

Coronavirus | Apr 5, 2020

King County, Wash., addresses homelessness and COVID-19 with rapid-response site conversions

The county is adding 2,500 beds within a dozen Assessment & Recovery Centers that DLR Group helped to design.

Coronavirus | Apr 4, 2020

COVID-19: Construction completed on first phase of Chicago's McCormick Place into Alternate Care Facility

Walsh Construction, one of the largest contractors in the city of Chicago and in the United States, is leading the temporary conversion of a portion of the McCormick Place Convention Center into an Alternate Care Facility (ACF) for novel coronavirus patients. Construction on the first 500 beds was completed on April 3.