During the coronavirus outbreak, wellness often took center stage in discussions about long-term infection control strategies.

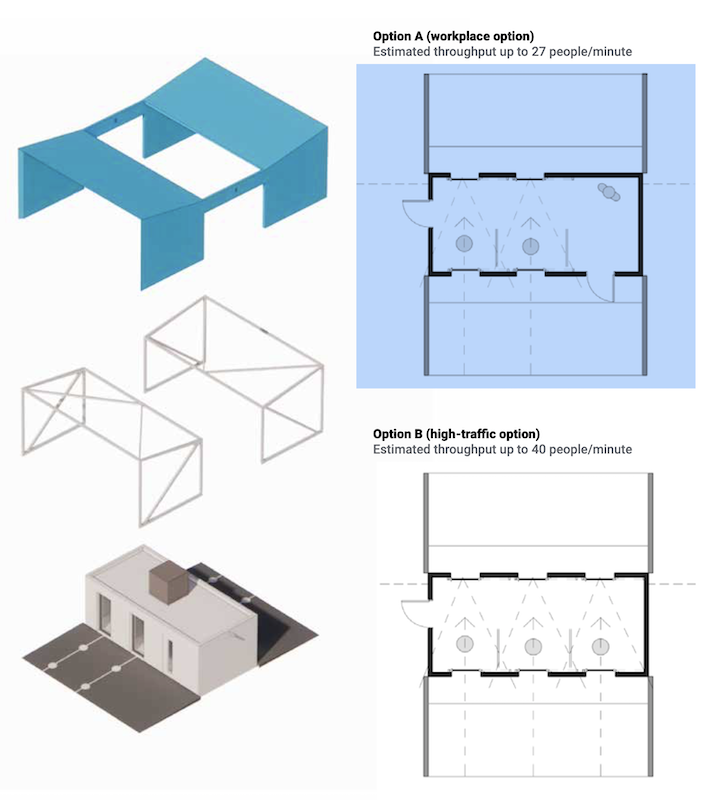

Leo A Daly and Turner Construction have partnered on the development of a design-build concept called WorkWell™, an assembly of prefabricated components designed to allow employers, schools, venues, airports and public spaces to efficiently screen large groups of entrants for signs of infectious disease.

The WorkWell™ modular point of entry offers a safe and welcoming setting for health screening of individuals entering high-traffic buildings and public spaces. The centerpiece is the entry pavilion, installed in any area where a controlled checkpoint is needed. Individuals are quickly checked for fever and potentially screened for other health risk factors. The pavilion is designed for touchless operation and includes air handling systems capable of controlling the transfer of airborne pathogens.

“It’s important for that health screening be a pleasant and welcoming experience,” says Daniel Yudchitz, AIA, Senior Design Architect with Leo A Daly. “We designed WorkWell™ to be an enhancement to a facility, not an ordeal. It should inspire confidence in the health and safety of everyone entering.”

WorkWell's modular design is adjustable for different locations and levels of anticipated screening capacity.

PREFABRICATION SPEEDS INSTALLATION PROCESS

WorkWell™ modules are fabricated in an automated shop environment for speed of implementation, product quality and contractor safety. Design-build delivery enables the units to be deployed rapidly at a competitive price point. Offsite fabrication and plug-and-play design require minimal need for onsite construction crews.

“Prefabrication and modularization allow us to meet aggressive schedules while maintaining a high level of quality control and minimizing the potential for on-site safety incidents,” says Brian Knowles, LEED AP, DBIA, industrial executive at Turner Construction. “By deploying rapidly and at scale, we can keep workforces and the public healthy and facilities safely operational.”

The marketing campaign for WorkWell launched last Thursday. The product doesn’t have a specific client yet, but the development team is in discussions with several prospects.

The cost of each installation will depend on the application, options chosen, and features chosen. Knowles tells BD+C that, the expected range is from $260,000 to $320,000. “We are looking at six-to-nine weeks for full occupancy from date of confirmed order/scope.”

Related Stories

Fire and Life Safety | Jun 9, 2020

NFPA develops business reopening checklist for fire and life safety measures

The new checklist helps building owners and facility managers ensure fire and life safety as businesses prepare to re-open amid the coronavirus pandemic.

Coronavirus | Jun 9, 2020

CannonDesign unveils COVID Shield

As the world evolves its response to the COVID-19 pandemic, one clear reality is testing for the virus will be part of our daily lives for the foreseeable future.

Coronavirus | Jun 5, 2020

3 strategies to improve the wellness of building systems and gain tenant trust

Three operational issues that must be prioritized for every building in order to achieve tenant trust are air quality/ventilation, relative humidity, and building commissioning.

Coronavirus | Jun 2, 2020

5 ways to improve hand washing and minimize germs in public restrooms

Bradley Corp. offers five upgrades to make public restrooms more sanitary.

Coronavirus | Jun 2, 2020

Perkins and Will, Healthy Building Network advise against the use of antimicrobial building products

Even during a pandemic, antimicrobial building products may do more harm than good.

Coronavirus | May 29, 2020

Black & Veatch, DPR, Haskell, McCarthy launch COVID-19 construction safety coalition

The NEXT Coalition will challenge engineering and construction firms to enhance health and safety amid the Coronavirus pandemic.

Coronavirus | May 28, 2020

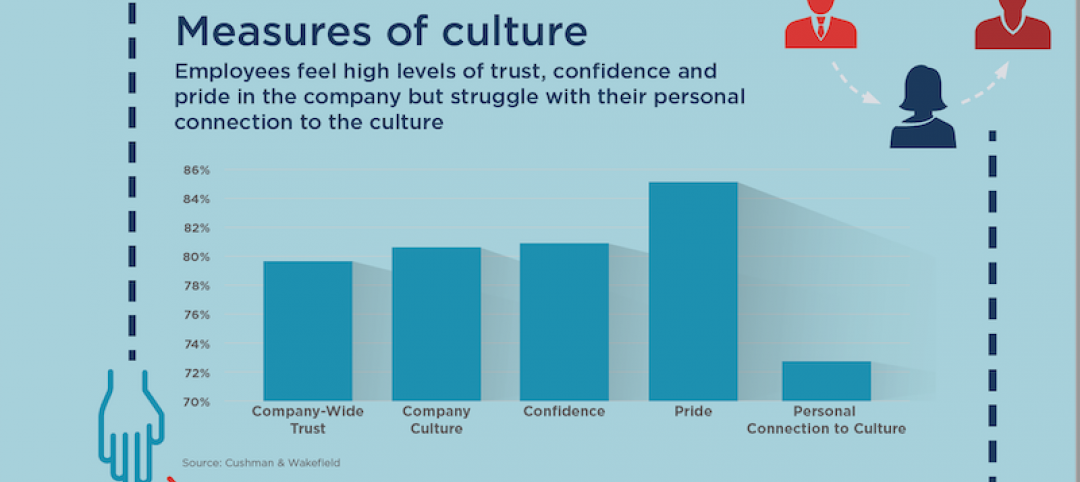

Cushman & Wakefield report examines work-at-home pros and cons

The office, now part of a larger workplace ecosystem, still reinforces employees’ connections with their companies.

Coronavirus | May 27, 2020

Clean is the new Green as U.S. hospitality sector inches closer to reopening

Three design firms share their takes on what will make customers more comfortable about returning.

Coronavirus | May 26, 2020

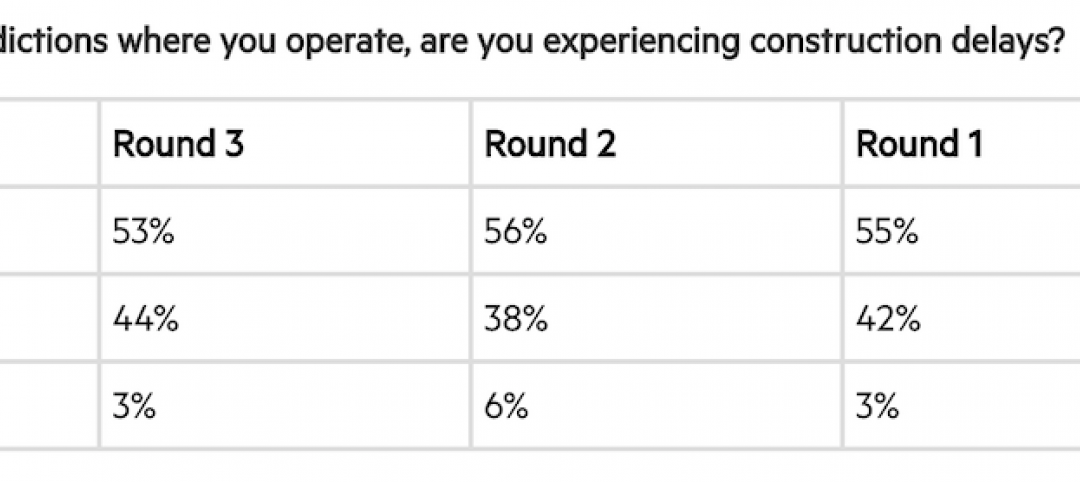

Multifamily developers report mounting delays in permitting and starts due to coronavirus pandemic

More than half (53%) of multifamily developer respondents reported construction delays in the jurisdictions where they operate, according to the third edition of the National Multifamily Housing Council (NMHC) COVID-19 Construction Survey.

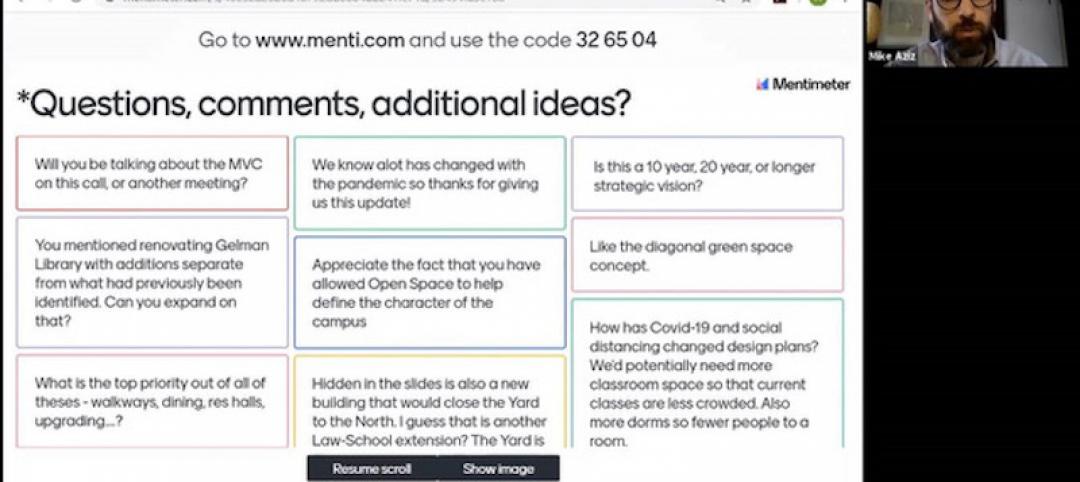

Coronavirus | May 26, 2020

9 tips for mastering virtual public meetings during the COVID-19 pandemic

Mike Aziz, AIA, presents 9 tips for mastering virtual public meetings during the COVID-19 pandemic.