During the coronavirus outbreak, wellness often took center stage in discussions about long-term infection control strategies.

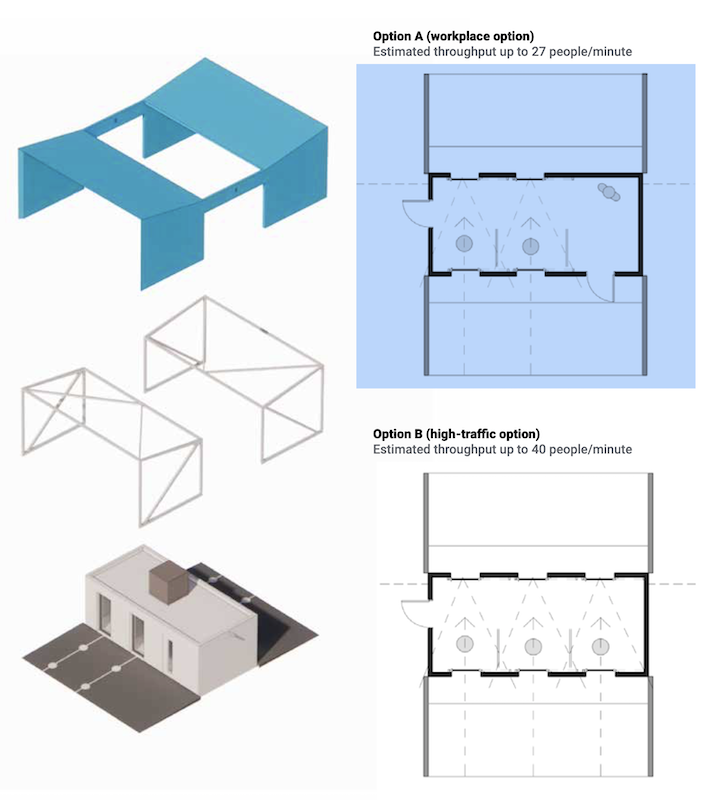

Leo A Daly and Turner Construction have partnered on the development of a design-build concept called WorkWell™, an assembly of prefabricated components designed to allow employers, schools, venues, airports and public spaces to efficiently screen large groups of entrants for signs of infectious disease.

The WorkWell™ modular point of entry offers a safe and welcoming setting for health screening of individuals entering high-traffic buildings and public spaces. The centerpiece is the entry pavilion, installed in any area where a controlled checkpoint is needed. Individuals are quickly checked for fever and potentially screened for other health risk factors. The pavilion is designed for touchless operation and includes air handling systems capable of controlling the transfer of airborne pathogens.

“It’s important for that health screening be a pleasant and welcoming experience,” says Daniel Yudchitz, AIA, Senior Design Architect with Leo A Daly. “We designed WorkWell™ to be an enhancement to a facility, not an ordeal. It should inspire confidence in the health and safety of everyone entering.”

WorkWell's modular design is adjustable for different locations and levels of anticipated screening capacity.

PREFABRICATION SPEEDS INSTALLATION PROCESS

WorkWell™ modules are fabricated in an automated shop environment for speed of implementation, product quality and contractor safety. Design-build delivery enables the units to be deployed rapidly at a competitive price point. Offsite fabrication and plug-and-play design require minimal need for onsite construction crews.

“Prefabrication and modularization allow us to meet aggressive schedules while maintaining a high level of quality control and minimizing the potential for on-site safety incidents,” says Brian Knowles, LEED AP, DBIA, industrial executive at Turner Construction. “By deploying rapidly and at scale, we can keep workforces and the public healthy and facilities safely operational.”

The marketing campaign for WorkWell launched last Thursday. The product doesn’t have a specific client yet, but the development team is in discussions with several prospects.

The cost of each installation will depend on the application, options chosen, and features chosen. Knowles tells BD+C that, the expected range is from $260,000 to $320,000. “We are looking at six-to-nine weeks for full occupancy from date of confirmed order/scope.”

Related Stories

Coronavirus | Apr 15, 2020

3D printing finds its groove fabricating face shields during COVID-19 crisis

The architecture firm Krueck + Sexton is producing 100 shields for a Chicago-area hospital.

Coronavirus | Apr 14, 2020

COVID-19 alert: Missouri’s first Alternate Care Facility ready for coronavirus patients

Missouri’s first Alternate Care Facility ready for coronavirus patients

Coronavirus | Apr 13, 2020

COVID-19 alert: City conducts a 'virtual building inspection' to allow Starbucks and bank to open

Bothell, Wash., issues a certificate of occupancy to developer after inspecting the property online.

Coronavirus | Apr 13, 2020

Construction layoffs spread rapidly as coronavirus shuts down projects, in contrast to job gains through February in most metros

Association officials urge quick enactment of infrastructure investment, relief for hard-hit firms and pensions in order to save jobs in construction and supplier industries.

Coronavirus | Apr 12, 2020

How prefab can enable the design and construction industry to bring much needed beds to hospitals, faster

The outbreak of COVID-19 represents an unprecedented test for the global healthcare system. Managing the pandemic—and saving lives—depends largely on the availability of medical supplies, including the capacity of hospitals. But the United States lags behind other nations, with only 2.8 beds per thousand people compared to 4.3 in China and 12.8 in South Korea.

Coronavirus | Apr 10, 2020

HGA and The Boldt Company devise a prefabricated temporary hospital to manage surge capacity during a viral crisis

A STAAT Mod system can be ready to receive patients in less than a month.

Coronavirus | Apr 10, 2020

COVID-19: Converting existing hospitals, hotels, convention centers, and other alternate care sites for coronavirus patients

COVID-19: Converting existing unused or underused hospitals, hotels, convention centers, and other alternate care sites for coronavirus patients

Coronavirus | Apr 9, 2020

COVID-19 Design Innovation Grant: IDA offers $14,000 to spur design innovation for combating the coronavirus pandemic

The International Design Awards is looking for innovations in low-cost ventilators, in-home isolation pods, and reusable masks.

Coronavirus | Apr 9, 2020

COVID-19 alert: Robins & Morton to convert Miami Beach Convention Center into a 450-bed field hospital

COVID-19 alert: Robins & Morton to convert Miami Beach Convention Center into a 450-bed field hospital

Coronavirus | Apr 8, 2020

AIA task force launches tool for assessing COVID-19 alternative care sites

The tool is intended to assist non-healthcare design professionals with identifying alternative sites suitable for patient care.