Purdue University civil engineers have developed innovative materials that can dissipate energy caused by bending, compression, torque, and tensile stresses without sustaining permanent damage. These intelligent architected materials may also possess shape memory properties, making them reusable while enhancing safety and durability.

The research, led by Professor Pablo Zavattieri, believe the new class of adaptable materials offer potential uses in multiple industries, such as earthquake engineering, impact-resistant structures, biomedical devices, sporting goods, building construction, and automotive components. The technology is currently being tested for 3D-printed panels for aircraft runway mats and nonpneumatic tires for military vehicles, providing resistance to punctures and leaks while maintaining performance in various terrains.

Purdue develops intelligent architected materials

“These materials are designed for fully recoverable, energy-dissipating structures, akin to what is referred to as architected shape memory materials, or phase transforming cellular materials, known as PXCM,” Zavattieri said. “They can also exhibit intelligent responses to external forces, changes in temperature, and other external stimuli.”

These materials can be created from various substances, such as polymers, rubber, and concrete, as long as they remain within the elastic range. They are designed to deform in controlled and programmable ways, providing enhanced energy absorption and adaptability. For the aircraft runway mats, Zavattieri sees the material aiding in self-healing properties, resulting in a longer life span than a runway made with AM-2 matting. "Another benefit is that debris on the runway will not hamper the runway’s performance with our technology," he says.

The Purdue researchers have demonstrated scalability from macro to micro applications and an improvement over traditional lightweight cellular materials.

“We have produced intelligent architected materials as large as 12 inches, which are ideal for applications like building and bridge construction to absorb and harness energy,” Zavattieri said. “Conversely, we have created materials with unit cells smaller than the thickness of a human hair. This scalability opens up a world of possibilities from macro to micro applications.”

The research has received funding from organizations like General Motors, ITAMCO (Indiana Technology and Manufacturing Companies), the National Science Foundation, and the U.S. Air Force. Additionally, patents have been filed to protect the intellectual property, and industry partners interested in commercializing the materials for the marketplace should contact Dipak Narula, Assistant Director of Business Development and Licensing in Physical Sciences, at dnarula@prf.org about 2018-ZAVA-68252, 2019-ZAVA-68691, 2020-ZAVA-69072 and 2022-ZAVA-69900.

Related Stories

| Mar 20, 2014

Common EIFS failures, and how to prevent them

Poor workmanship, impact damage, building movement, and incompatible or unsound substrate are among the major culprits of EIFS problems.

| Mar 20, 2014

13 dazzling wood building designs [slideshow]

From bold structural glulam designs to striking textured wall and ceiling schemes, these award-winning building projects showcase the design possibilities using wood.

| Mar 19, 2014

Federal agency gives thumbs up to tall wood buildings

USDA's support for wood projects includes training for AEC professionals and a wood high-rise design competition, to launch later this year.

| Mar 17, 2014

Rem Koolhaas explains China's plans for its 'ghost cities'

China's goal, according to Koolhaas, is to de-incentivize migration into already overcrowded cities.

| Mar 12, 2014

14 new ideas for doors and door hardware

From a high-tech classroom lockdown system to an impact-resistant wide-stile door line, BD+C editors present a collection of door and door hardware innovations.

| Mar 10, 2014

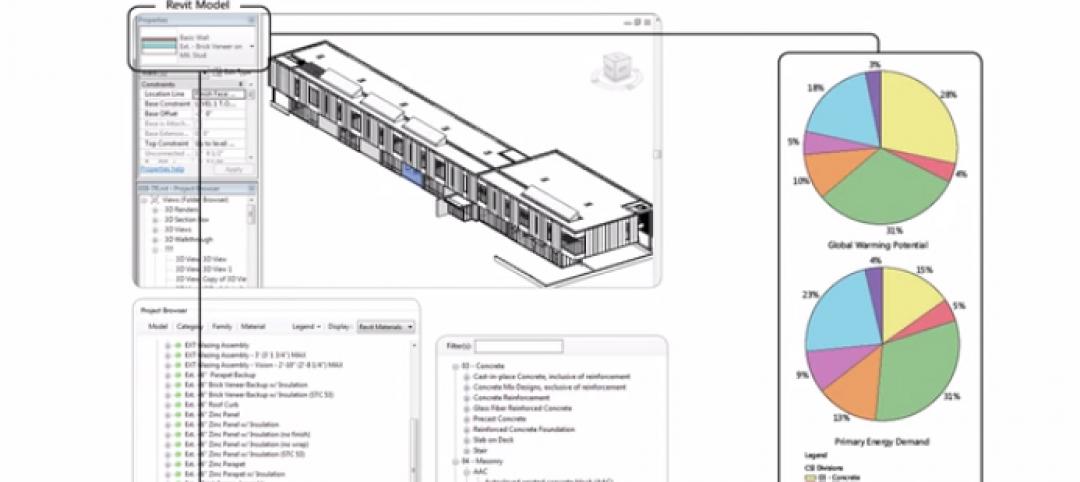

Meet Tally – the Revit app that calculates the environmental impact of building materials

Tally provides AEC professionals with insight into how materials-related decisions made during design influence a building’s overall ecological footprint.

| Mar 5, 2014

5 tile design trends for 2014

Beveled, geometric, and high-tech patterns are among the hot ceramic tile trends, say tile design experts.

| Mar 4, 2014

How EIFS came to America

Design experts from Hoffmann Architects offer a brief history of exterior insulation and finish systems in the U.S.

| Feb 27, 2014

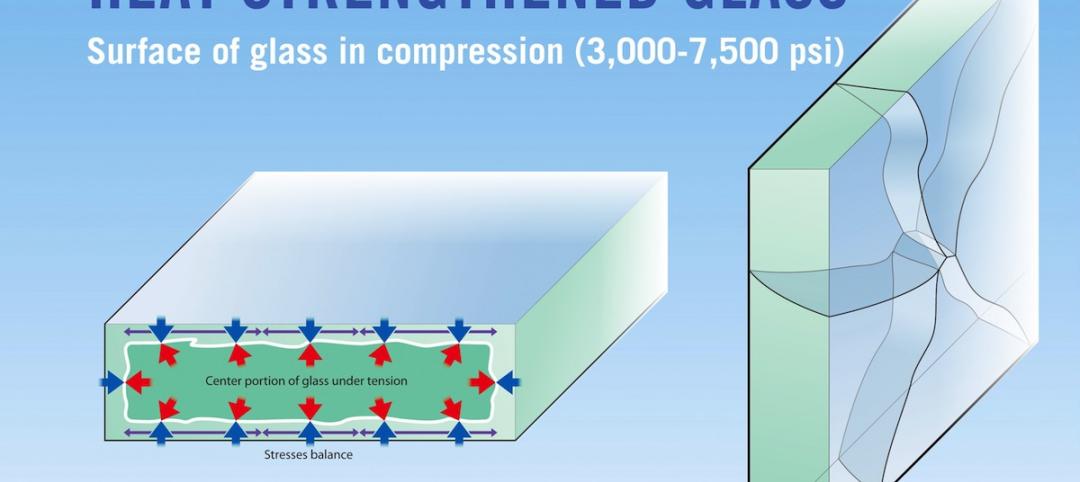

12 facts about heat-treated glass: Why stronger isn’t always better

Glass is heat-treated for two reasons: the first is to increase its strength to resist external stresses such as wind and snow loads, or thermal loads caused by the sun’s energy. The second is to temper glass so that it meets safety glazing requirements defined by applicable codes or federal standards.

| Feb 27, 2014

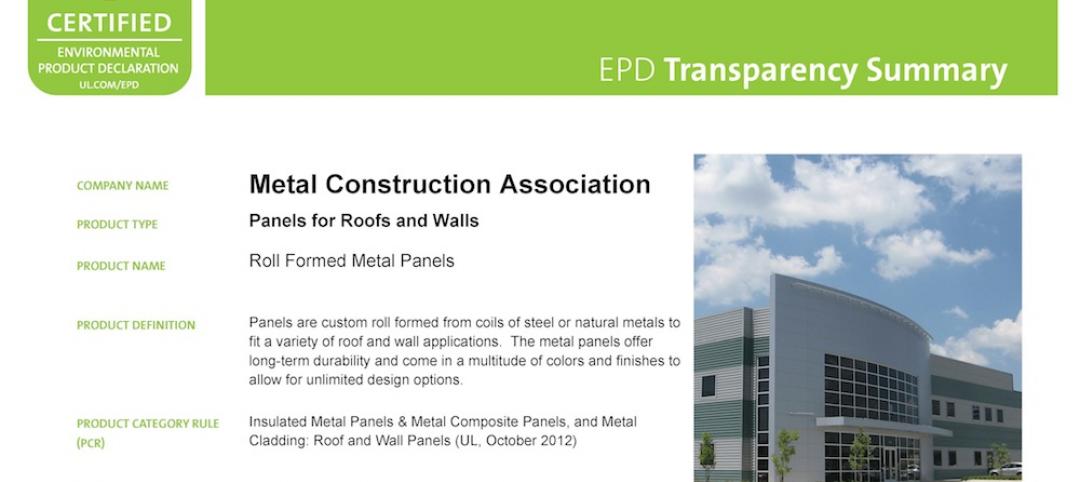

Metal Construction Association introduces two Environmental Product Declarations

Two Environmental Product Declarations (EPD), one for Metal Composite Material Panels and one for Roll Formed Steel Panels for Roofs and Walls, are now available free of charge from the Metal Construction Association (MCA) on its website.