Using the latest 3D printing techniques, or more accurately, "additive manufacturing," the Arup team has produced a design method for critical structural steel elements for use in complex projects.

The work signals a whole new direction for the use of additive manufacturing in the field of construction and engineering. The research also shows that additive manufacturing has the potential to reduce costs, cut waste and slash the carbon footprint of the construction sector.

We created a redesign of a steel node for a light weight structure using additive manufacturing. Arup has a lot of experience with these kind of structures, for example, the tensegrity structure of the Kurilpa Bridge in Australia. The complex geometry of these kind of nodes are an ideal showcase of the possibilities of this new technique.

"By using additive manufacturing we can create lots of complex individually designed pieces far more efficiently," said Salomé Galjaard, Arup's team leader on the project. "This has tremendous implications for reducing costs and cutting waste. But most importantly, this approach potentially enables a very sophisticated design, without the need to simplify the design in a later stage to lower costs.”

Arup funded the development work and collaborated with a number of partners to realize the designs, including WithinLab (an engineering design software and consulting company), CRDM/3D Systems (the Additive Manufacturing partner), and EOS, who worked on the early development of the technology.

For more, visit: http://www.arup.com/News/2014_06_June/05_June_Construction_steelwork_makes_3D_printing_premiere.aspx.

3D Printed Steel Node

By using 3D printing, or "additive manufacturing," complex individually designed pieces can be created far more efficiently.

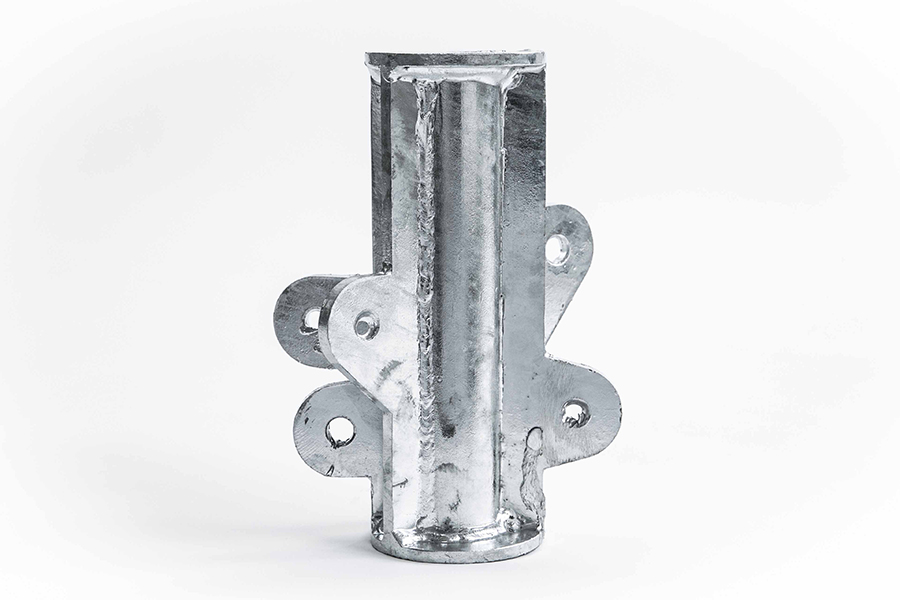

Traditionally Fabricated Node

A traditionally produced steel node is at the moment still cheaper to produce, but it is expected that this will change in the short term.

Related Stories

| Aug 11, 2010

Jacobs, HOK top BD+C's ranking of the 75 largest state/local government design firms

A ranking of the Top 75 State/Local Government Design Firms based on Building Design+Construction's 2009 Giants 300 survey. For more Giants 300 rankings, visit http://www.BDCnetwork.com/Giants

| Aug 11, 2010

Clark Group, Hensel Phelps among nation's largest federal government contractors, according to BD+C's Giants 300 report

A ranking of the Top 40 Federal Government Contractors based on Building Design+Construction's 2009 Giants 300 survey. For more Giants 300 rankings, visit http://www.BDCnetwork.com/Giants

| Aug 11, 2010

Jacobs, HDR top BD+C's ranking of the nation's 100 largest institutional building design firms

A ranking of the Top 100 Institutional Design Firms based on Building Design+Construction's 2009 Giants 300 survey. For more Giants 300 rankings, visit http://www.BDCnetwork.com/Giants

| Aug 11, 2010

Earthquake engineering keeps airport grounded

Istanbul, Turkey's new 2.15 million-sf Sabiha Gökçen International Airport opened on October 31, 2009, becoming the world's largest seismically isolated building. Arup's global airport planning and engineering team, in collaboration with architects Dogan Tekeli Sami Sisa Mimarlik Ofisi and contractor LIMAK-GMR JV, working within an 18-month timeline, designed and built the facility wi...