Using the latest 3D printing techniques, or more accurately, "additive manufacturing," the Arup team has produced a design method for critical structural steel elements for use in complex projects.

The work signals a whole new direction for the use of additive manufacturing in the field of construction and engineering. The research also shows that additive manufacturing has the potential to reduce costs, cut waste and slash the carbon footprint of the construction sector.

We created a redesign of a steel node for a light weight structure using additive manufacturing. Arup has a lot of experience with these kind of structures, for example, the tensegrity structure of the Kurilpa Bridge in Australia. The complex geometry of these kind of nodes are an ideal showcase of the possibilities of this new technique.

"By using additive manufacturing we can create lots of complex individually designed pieces far more efficiently," said Salomé Galjaard, Arup's team leader on the project. "This has tremendous implications for reducing costs and cutting waste. But most importantly, this approach potentially enables a very sophisticated design, without the need to simplify the design in a later stage to lower costs.”

Arup funded the development work and collaborated with a number of partners to realize the designs, including WithinLab (an engineering design software and consulting company), CRDM/3D Systems (the Additive Manufacturing partner), and EOS, who worked on the early development of the technology.

For more, visit: http://www.arup.com/News/2014_06_June/05_June_Construction_steelwork_makes_3D_printing_premiere.aspx.

3D Printed Steel Node

By using 3D printing, or "additive manufacturing," complex individually designed pieces can be created far more efficiently.

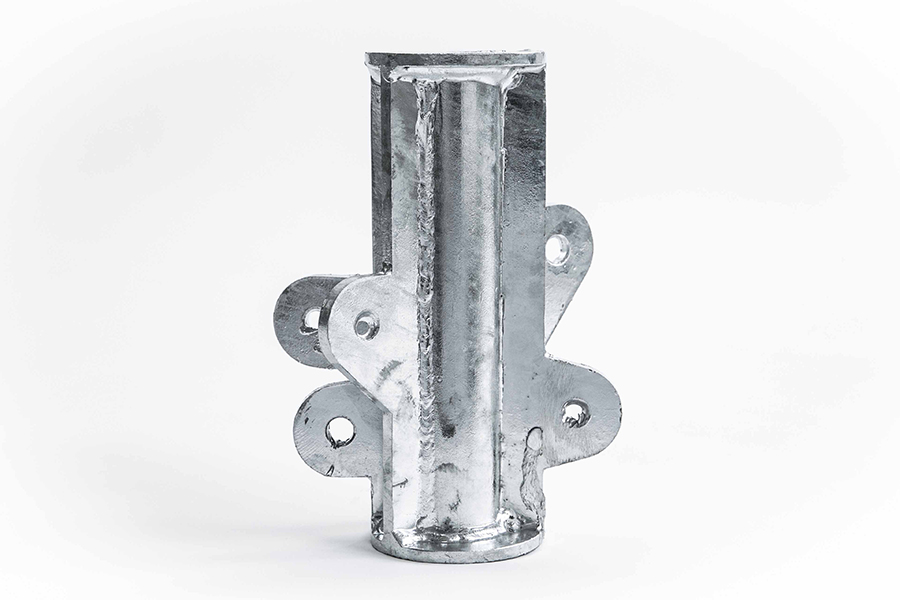

Traditionally Fabricated Node

A traditionally produced steel node is at the moment still cheaper to produce, but it is expected that this will change in the short term.

Related Stories

| Aug 28, 2013

Federal Government Report [2013 Giants 300 Report]

Building Design+Construction's rankings of the nation's largest federal government design and construction firms, as reported in the 2013 Giants 300 Report.

| Aug 26, 2013

What you missed last week: Architecture billings up again; record year for hotel renovations; nation's most expensive real estate markets

BD+C's roundup of the top construction market news for the week of August 18 includes the latest architecture billings index from AIA and a BOMA study on the nation's most and least expensive commercial real estate markets.

| Aug 22, 2013

Energy-efficient glazing technology [AIA Course]

This course discuses the latest technological advances in glazing, which make possible ever more efficient enclosures with ever greater glazed area.

| Aug 21, 2013

Why research is the ticket to successful airport wayfinding

Wayfinding is more than just signs; it requires a holistic approach based on communicating information that helps people make the right decision at the right time.

| Aug 19, 2013

Discovery of hidden asbestos complicates DFW terminal renovations

The finding of more asbestos in Terminal B than expected, and the pending merger of US Airways and the airport’s largest tenant, American Airlines, is causing construction delays on a $2.3 billion Dallas/Fort Worth Airport terminal renovation.

| Aug 19, 2013

Integration of solar panels in building skin seen as key net-zero element

Recent high-profile projects, including stadiums in Brazil for the upcoming World Cup and Summer Olympics and a bank headquarters in the U.K., reflect an effort by designers to adopt building-integrated photovoltaics, or BIPV.

| Aug 14, 2013

Green Building Report [2013 Giants 300 Report]

Building Design+Construction's rankings of the nation's largest green design and construction firms.

| Jul 29, 2013

2013 Giants 300 Report

The editors of Building Design+Construction magazine present the findings of the annual Giants 300 Report, which ranks the leading firms in the AEC industry.

| Jul 22, 2013

Transportation Facility Report [2013 Giants 300 Report]

Building Design+Construction's rankings of design and construction firms with the most revenue from airport terminals and other transportation-related facilities, as reported in the 2013 Giants 300 Report.

| Jul 19, 2013

Renovation, adaptive reuse stay strong, providing fertile ground for growth [2013 Giants 300 Report]

Increasingly, owners recognize that existing buildings represent a considerable resource in embodied energy, which can often be leveraged for lower front-end costs and a faster turnaround than new construction.