During the coronavirus outbreak, wellness often took center stage in discussions about long-term infection control strategies.

Leo A Daly and Turner Construction have partnered on the development of a design-build concept called WorkWell™, an assembly of prefabricated components designed to allow employers, schools, venues, airports and public spaces to efficiently screen large groups of entrants for signs of infectious disease.

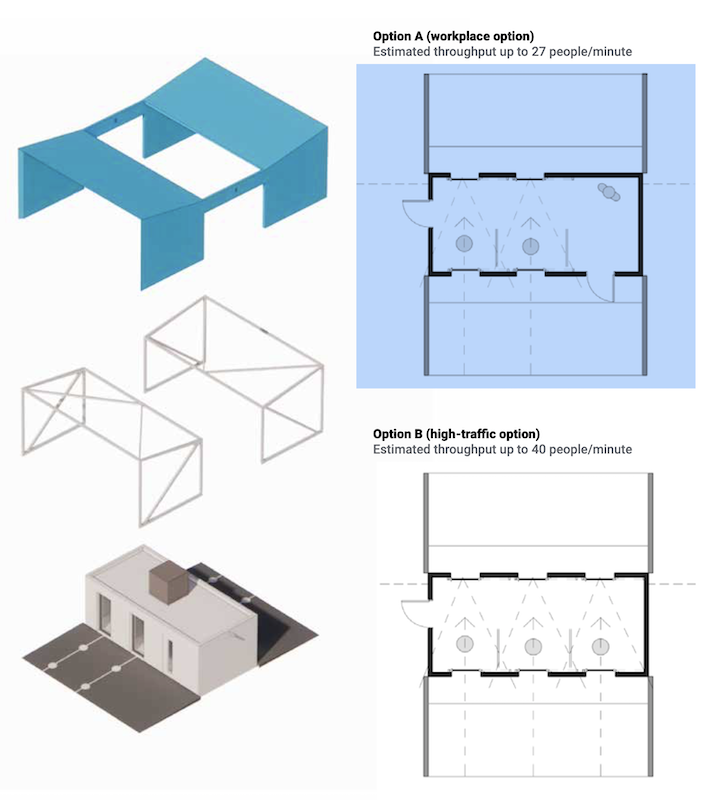

The WorkWell™ modular point of entry offers a safe and welcoming setting for health screening of individuals entering high-traffic buildings and public spaces. The centerpiece is the entry pavilion, installed in any area where a controlled checkpoint is needed. Individuals are quickly checked for fever and potentially screened for other health risk factors. The pavilion is designed for touchless operation and includes air handling systems capable of controlling the transfer of airborne pathogens.

“It’s important for that health screening be a pleasant and welcoming experience,” says Daniel Yudchitz, AIA, Senior Design Architect with Leo A Daly. “We designed WorkWell™ to be an enhancement to a facility, not an ordeal. It should inspire confidence in the health and safety of everyone entering.”

WorkWell's modular design is adjustable for different locations and levels of anticipated screening capacity.

PREFABRICATION SPEEDS INSTALLATION PROCESS

WorkWell™ modules are fabricated in an automated shop environment for speed of implementation, product quality and contractor safety. Design-build delivery enables the units to be deployed rapidly at a competitive price point. Offsite fabrication and plug-and-play design require minimal need for onsite construction crews.

“Prefabrication and modularization allow us to meet aggressive schedules while maintaining a high level of quality control and minimizing the potential for on-site safety incidents,” says Brian Knowles, LEED AP, DBIA, industrial executive at Turner Construction. “By deploying rapidly and at scale, we can keep workforces and the public healthy and facilities safely operational.”

The marketing campaign for WorkWell launched last Thursday. The product doesn’t have a specific client yet, but the development team is in discussions with several prospects.

The cost of each installation will depend on the application, options chosen, and features chosen. Knowles tells BD+C that, the expected range is from $260,000 to $320,000. “We are looking at six-to-nine weeks for full occupancy from date of confirmed order/scope.”

Related Stories

Coronavirus | Apr 4, 2020

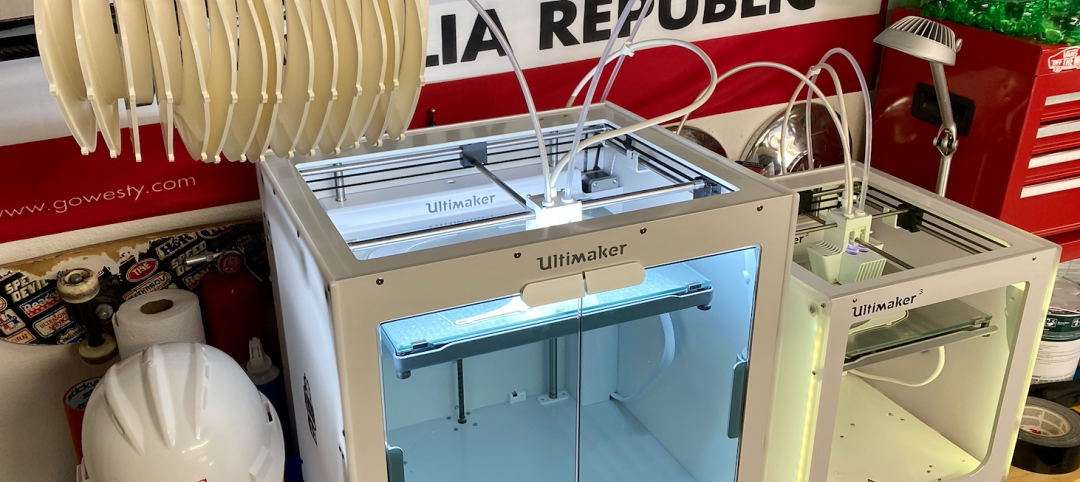

COVID-19: Architecture firms churn out protective face shields using their 3D printers

Architecture firms from coast to coast have suddenly turned into manufacturing centers for the production of protective face shields and face masks for use by healthcare workers fighting the COVID-10 pandemic.

Coronavirus | Apr 3, 2020

Cities will survive the pandemic

Density may make it easier for the virus to spread, but let’s not forget that cities are in many ways the heart of society, and a springboard of big ideas, inventions, art, and culture.

Coronavirus | Apr 3, 2020

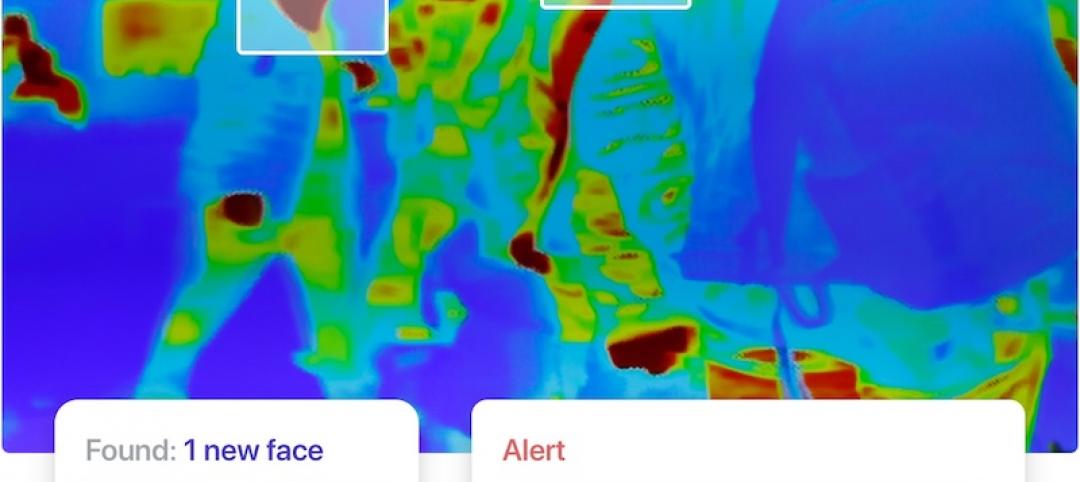

Kogniz Health launches AI-based fever detection cameras for crowds to help limit coronavirus spread

System continuously scans crowds for fever as they enter facilities to locate and isolate risks.

Coronavirus | Apr 3, 2020

27% of construction firms report layoffs amid COVID-19 outbreak, says AGC

The fast-worsening COVID-19 pandemic has triggered layoffs at more than a quarter of construction firms responding to an online survey released today by the Associated General Contractors of America. The finding, based on responses from earlier this week, contrasts with the government’s monthly employment report for March, which found that construction employment declined by 29,000 as of mid-March.

Coronavirus | Apr 3, 2020

Test facility in a box: Modular, walk-in booth design for coronavirus testing

To address the need for testing in urban areas for those without vehicles, CannonDesign architect Albert Rhee created a walk-in testing booth that is slated for public use.

Coronavirus | Apr 3, 2020

Survey of U.S. code officials shows trends in code compliance during COVID-19

The results of the survey tell us how jurisdictions throughout the U.S. are keeping up with inspections, new building permits and new construction.

Coronavirus | Apr 3, 2020

CallisonRTKL buoyed by overseas demand

Customer service across the globe remains No. 1 priority, says new CFO.

Coronavirus | Apr 2, 2020

COVID-19: HMC Architects using 3D Printers to make face shields for healthcare workers

HMC staff is producing 3D-printed parts from their homes as they self-isolate.

Coronavirus | Apr 2, 2020

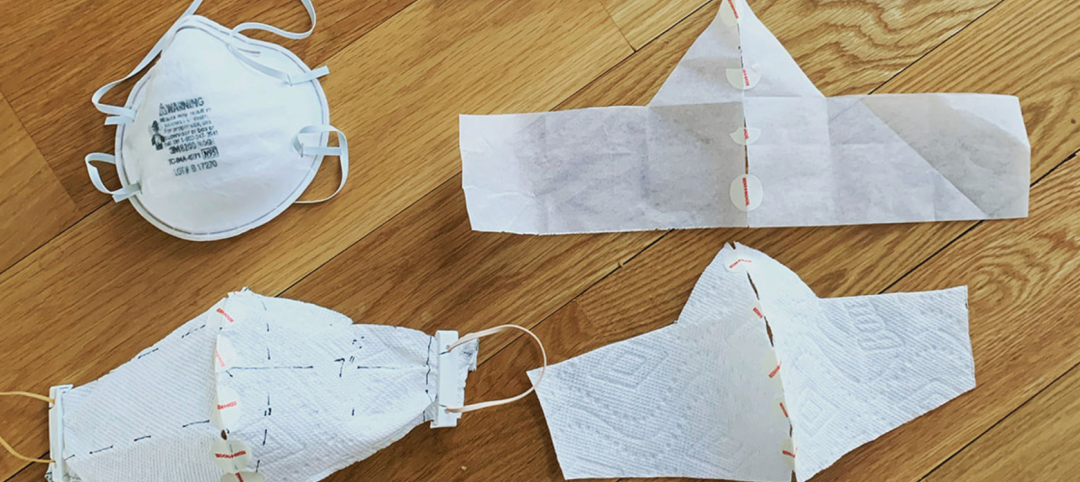

COVID-19: CannonDesign initiates industry coalition to make masks for healthcare providers

Coalition formed to make DIY face masks for healthcare workers in COVID-19 settings.

Coronavirus | Apr 2, 2020

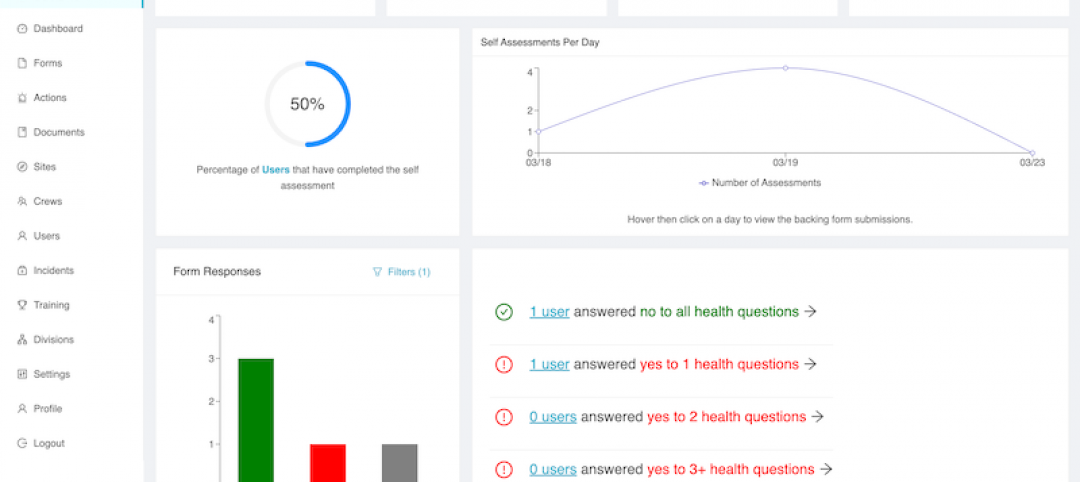

As virus spreads across North America, software providers step up with cost-free offerings

The goal is to keep construction projects moving forward at a time when jobs are being postponed or canceled.