When the general contractor learned that this newly constructed building’s concrete substrate had an average of one-inch deflection, the flooring contractor recommended a cementitious self-leveling underlayment to correct and flatten the floor. The GC anticipated that solving the problem would negatively affect the project schedule - they needed a fast and reliable solution.

Traditional installation methods would be time-consuming, costly and introduce unacceptable levels of respirable silica dust to the jobsite and to worker safety. The flooring contractor, Allegheny Contract, challenged using old, traditional SLU installation methods and recommended using the LATICRETE SUPERCAP system.

Allegheny Contract offered to conduct a monitored side-by-side comparison test using two different premium SLU products.

The General Contractor agreed and selected 2 identical 11,000 SF floor plates:

- Floor 4: Was installed with 50lb small bags of self-leveling underlayment loaded into the building on pallets and delivered through a traditional barrel mixing system.

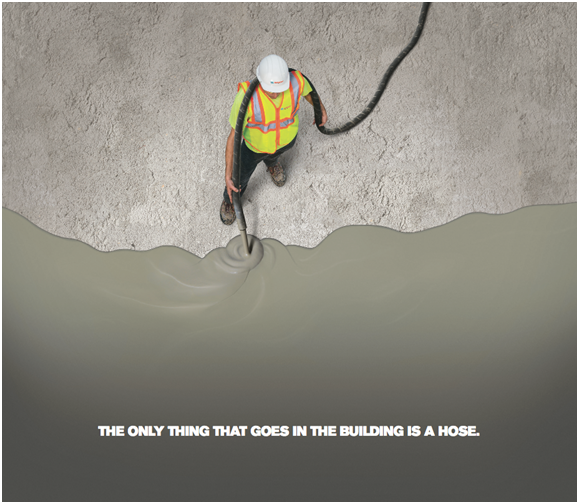

- Floor 5: Was installed with the LATICRETE SUPERCAP System, using 2,300lb supersacks of SC500 material mixed outside the building in a mobile blending unit and pumped through a hose into the building.

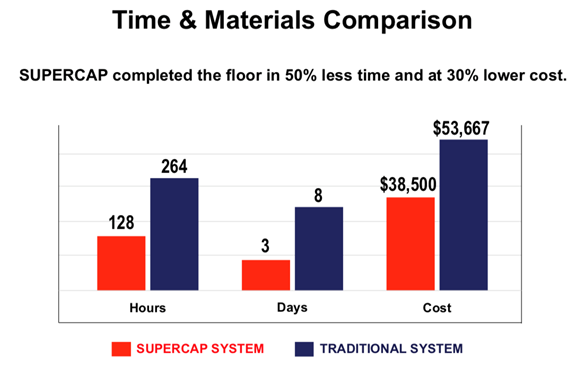

The Results:

The LATICRETE SUPERCAP System had the speed and volume, the mobile blending unit can pump up to 60 stories high, up to 50,000 SF in one day, at a rate of 30,000 lbs. per hour (equivalent to 600 small bags an hour). The only thing that goes into the building is a hose, no silica dust inside or outside the building. The projects LVT and wood floor flatness specs were easily met and the project stayed on schedule. The goal of providing a fast and cost-effective solution was achieved.

For more information, contact LATICRETE SUPERCAP at (866) 704-2247 or email us at info@laticretesupercap.com, or visit www.laticretesupercap.com

To view a project video of another LATICRETE SUPERCAP System Solution, visit: https://laticretesupercap.com/en/features-support/project-spotlights/colorado-mills-mall