When the general contractor learned that this newly constructed building’s concrete substrate had an average of one-inch deflection, the flooring contractor recommended a cementitious self-leveling underlayment to correct and flatten the floor. The GC anticipated that solving the problem would negatively affect the project schedule - they needed a fast and reliable solution.

Traditional installation methods would be time-consuming, costly and introduce unacceptable levels of respirable silica dust to the jobsite and to worker safety. The flooring contractor, Allegheny Contract, challenged using old, traditional SLU installation methods and recommended using the LATICRETE SUPERCAP system.

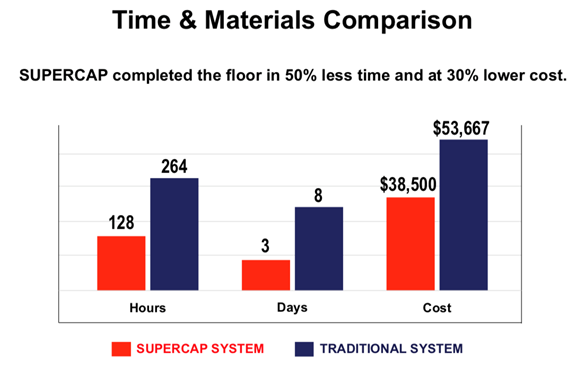

Allegheny Contract offered to conduct a monitored side-by-side comparison test using two different premium SLU products.

The General Contractor agreed and selected 2 identical 11,000 SF floor plates:

- Floor 4: Was installed with 50lb small bags of self-leveling underlayment loaded into the building on pallets and delivered through a traditional barrel mixing system.

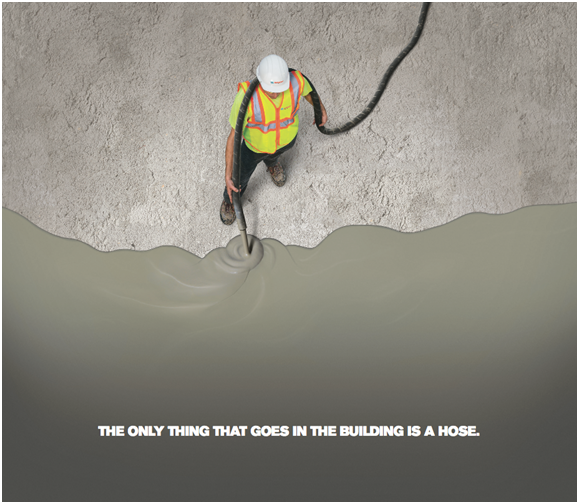

- Floor 5: Was installed with the LATICRETE SUPERCAP System, using 2,300lb supersacks of SC500 material mixed outside the building in a mobile blending unit and pumped through a hose into the building.

The Results:

The LATICRETE SUPERCAP System had the speed and volume, the mobile blending unit can pump up to 60 stories high, up to 50,000 SF in one day, at a rate of 30,000 lbs. per hour (equivalent to 600 small bags an hour). The only thing that goes into the building is a hose, no silica dust inside or outside the building. The projects LVT and wood floor flatness specs were easily met and the project stayed on schedule. The goal of providing a fast and cost-effective solution was achieved.

For more information, contact LATICRETE SUPERCAP at (866) 704-2247 or email us at info@laticretesupercap.com, or visit www.laticretesupercap.com

To view a project video of another LATICRETE SUPERCAP System Solution, visit: https://laticretesupercap.com/en/features-support/project-spotlights/colorado-mills-mall

Related Stories

| Jan 3, 2012

VDK Architects merges with Harley Ellis Devereaux

Harley Ellis Devereaux will relocate the employees in its current Berkeley, Calif., office to the new Oakland office location effective January 3, 2012.

| Dec 10, 2011

10 Great Solutions

The editors of Building Design+Construction present 10 “Great Solutions” that highlight innovative technology and products that can be used to address some of the many problems Building Teams face in their day-to-day work. Readers are encouraged to submit entries for Great Solutions; if we use yours, you’ll receive a $25 gift certificate. Look for more Great Solutions in 2012 at: www.bdcnetwork.com/greatsolutions/2012.

| Nov 28, 2011

Nauset Construction completes addition for Franciscan Hospital for Children

The $6.5 million fast-track, urban design-build projectwas completed in just over 16 months in a highly sensitive, occupied and operational medical environment.

| Nov 8, 2011

WEB EXCLUSIVE: Moisture-related failures in agglomerated floor tiles

Agglomerated tiles offer an appealing appearance similar to natural stone at a lower cost. To achieve successful installations, manufacturers should provide design data for moisture-related dimensional changes, specifiers should require in-situ moisture testing similar to those used for other flooring materials, and the industry should develop standards for fabrication and installation of agglomerated tiles.

| Oct 17, 2011

Big D Floor covering supplies to offer Johnsonite Products??

Strategic partnership expands offering to south and west coast customers.

| Oct 5, 2011

GREENBUILD 2011: Tile manufacturer attains third-party certification for waste recycling processes

Crossville has joined with TOTO to recycle that company’s pre-consumer fired sanitary ware.

| Oct 4, 2011

GREENBUILD 2011: Johnsonite features sustainable products

Products include rubber flooring tiles, treads, wall bases, and more.

| Sep 30, 2011

Design your own floor program

Program allows users to choose from a variety of flooring and line accent colors to create unique floor designs to complement any athletic facility.

| Sep 20, 2011

Jeanne Gang wins MacArthur Fellowship

Jeanne Gang, a 2011 MacArthur Fellowship winner described by the foundation as "an architect challenging the aesthetic and technical possibilities of the art form in a wide range of structures."