When embarking upon a roofing renovation project, one of the first decisions for the Building Team is whether to tear off and replace the existing roof or to overlay the new roof right on top of the old one.

“Typically, you’re reroofing because of leaks or damage to a roof,” says Shad Traylor, AIA, CDT, LEED AP BD+C, a LEED administrator with the design-build firm BRPH, Melbourne, Fla. “A tear-off allows you to inspect the condition of the roof substrate and is more favorable for roof warranties. If the load-bearing capacity of the roof substrate is in question, a tear-off also reduces the additional weight of a second roof.”

However, if the roof has minimal water damage, he adds, reroofing with an overlayment strategy can be the quickest, least expensive, and easiest solution because it eliminates tear-off costs and reduces replacement time. “Overlayment also allows owners to maintain a weather barrier if sensitive equipment and products are installed or stored below the roof,” adds Traylor.

Analysis and testing may be needed to determine if the existing roof structure is adequate to support the added weight of an overlay. This can involve core cuts in strategic areas to analyze material conditions, as well as thermal scans and insulation tests. According to Anthony Vross, owner of Simon Roofing, Youngstown, Ohio, a rule of thumb is that if more than 30-40% of the existing roof is wet, then a tear-off is in order. The same is true in situations where the existing roof system is ponding water and it is not possible to add drains or taper insulation with the perimeters or penetrations at least eight inches higher than the primary roof surface.

In some cases, the decision on the type of reroof may be dictated by the applicable building codes. For example, where two roofing systems are already in place, most jurisdictions won’t allow the addition of a third layer of overlayment. Consequently, a tear-off or full replacement is the only allowable option.

Another instance favoring tear-off is when mechanical equipment upgrades require the roof decking to be rebuilt, in which case tear-off provides the best continuity, says Mark Yanowitz, LEED AP, Assoc. AIA, UCSL, with design-build firm Verdeco Designs, Andover, Mass. “Although there have been significant improvements in new insulation adhesives that make quality overlay roofing projects more viable, tearing off an existing older roof almost always assures a better installation and fewer problems in the future,” he adds. “This is largely because there are no unknowns with attachment issues as to how the previous roof was installed and the integrity of the overall system.”

A number of other factors need to be taken into account, including the building type, location, building usage, roof access, roof traffic, penetrations, decking, and slope.

Other techniques similar to overlayment, such as spray-applied foam products, may be viable alternatives. Another retrofit path for green building projects is the use of a “cool roof” coating, which is fluid-applied directly to the exposed roofing material. Assuming that the roof’s surface is relatively smooth, moisture is not a major concern, and decent drainage is in place, these novel, light-colored roof coatings can be a cost-effective option.

“The extra benefit is that the coating type conforms to all shapes and sizes and seamlessly seals all potential water entry points that typically leak, including flashings, termination bars, corners, pipes, and curbs and the like, which don’t always conform to the shapes of traditional roofing materials,” explains David J. Welte, President of the consulting and commercial building maintenance contractor GreenPROChicago, Lake Forest, Ill.

Vegetated or planted roof coverings may also lend themselves to part of a reroofing strategy as overlayments. For extensive, unoccupied green roofs, a common strategy is to cover existing roofs with plantings in individual trays. With some products, it’s even possible to remove the dividers between the trays, once they’ve grown, at which point they become a seamless blanket of vegetation, says Blake Jackson, LEED AP, Sustainability Practice Leader with Tsoi/Kobus & Associates (www.tka-architects.com), Cambridge, Mass.

“This type of system is most appropriate when you want to cover a surface quickly,” says Jackson. “This will contribute to earning LEED credits and help in terms of building performance and rainwater management.”

In virtually every situation, the sequencing, phasing, and coordination of the roofing work is critical to successful, watertight tear-off installations. Contractors should work from the low point to the top of the roof to prevent back-lap areas that buck water, says David Cook, AIA, Principal Architect in structural and architectural evaluation with CTLGroup (www.C-T-L.com), Skokie, Ill. In addition, sections should be worked in a strategic sequence so that workers don’t have to walk across finished work surfaces.

Protecting the substrate or deck is another key point, says Jason Hand, Vice President of roofing contractor Property Development Solutions (www.pdscompany.com), Lubbock, Texas. This also goes for the building’s contents at times when sections of the roof are fully removed.

“Weather must be tracked and precautions made to dry-in the structure at a moment’s notice,” says Hand. He, too, emphasizes the importance of staging roof work in portions. “The building assemblies should also be torn off in stages to limit exposed area in the event of unexpected precipitation,” says Hand.

Craig R. Garey, owner of roofing contractor WeatherSure Systems (www.weathersuresystems.com), Sheridan, Colo., advises going from the inside of the facility outward in identifying liabilities, risks, deck conditions, and design prior to beginning any renovation. Once a sound plan is in place, a disposal chute is the best way to transfer debris from the roof to the ground, unless the building height exceeds 120 feet.

Yanowitz is a proponent of reusing insulation and stone products to the greatest extent possible once the membrane has been removed and replaced. In cases where on-site reuse isn’t practical, trash hauling companies with off-site recycling facilities are a good option so that contractors don’t have to spend the time segregating products on site.

A roofing retrofit that involves changing a flat roof to a steep slope system can present its own set of difficulties. For starters, the structural engineer must ensure that the weight of the new roof structure meets the proper load bearings and dead-load requirements, says Simon Roofing’s Vross. The architect must verify that the building’s new look meets aesthetic and building code demands.

“Going to a steep slope from a flat roof will change the drainage design, so an engineer will need to be consulted to make sure the existing drainage system can handle the increased flow of the water entering the drains,” he explains. “Due to the amount of air space between the structure and the flat roof, the proper amount of insulation needs to be installed to meet the building code and prevent condensation.”

Related Stories

K-12 Schools | Feb 13, 2024

K-12 school design trends for 2024: health, wellness, net zero energy

K-12 school sector experts are seeing “healthiness” for schools expand beyond air quality or the ease of cleaning interior surfaces. In this post-Covid era, “healthy” and “wellness” are intersecting expectations that, for many school districts, encompass the physical and mental wellbeing of students and teachers, greater access to outdoor spaces for play and learning, and the school’s connection to its community as a hub and resource.

Codes | Feb 9, 2024

Illinois releases stretch energy code for building construction

Illinois is the latest jurisdiction to release a stretch energy code that provides standards for communities to mandate more efficient building construction. St. Louis, Mo., and a few states, including California, Colorado, and Massachusetts, currently have stretch codes in place.

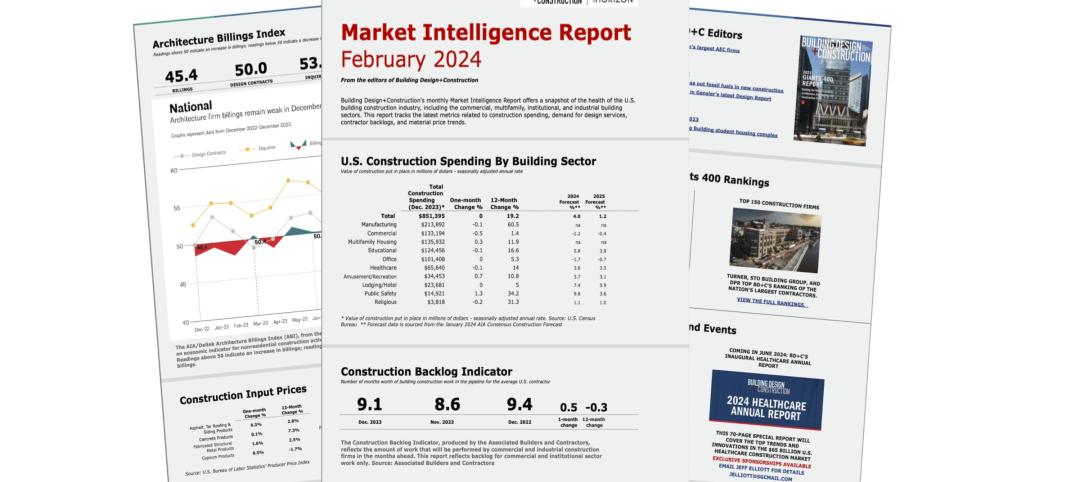

Market Data | Feb 7, 2024

New download: BD+C's February 2024 Market Intelligence Report

Building Design+Construction's monthly Market Intelligence Report offers a snapshot of the health of the U.S. building construction industry, including the commercial, multifamily, institutional, and industrial building sectors. This report tracks the latest metrics related to construction spending, demand for design services, contractor backlogs, and material price trends.

Retail Centers | Feb 4, 2024

‘Safe bathroom’ technology prevents fatal drug overdoses in public restrooms

‘Safe bathroom’ technology developed by a Massachusetts electrician has been proven to prevent fatal drug overdoses in public restrooms across the country. The systems use ultrasonic and infrared motion sensors connected to timers that detect slight body movements. When a system doesn’t sense motion within a set time period, it raises an alarm alerting emergency medical teams.

Standards | Feb 1, 2024

Prioritizing water quality with the WELL Building Standard

In this edition of Building WELLness, DC WELL Accredited Professionals Hannah Arthur and Alex Kircher highlight an important item of the WELL Building Standard: water.

Industry Research | Jan 23, 2024

Leading economists forecast 4% growth in construction spending for nonresidential buildings in 2024

Spending on nonresidential buildings will see a modest 4% increase in 2024, after increasing by more than 20% last year according to The American Institute of Architects’ latest Consensus Construction Forecast. The pace will slow to just over 1% growth in 2025, a marked difference from the strong performance in 2023.

Construction Costs | Jan 22, 2024

Construction material prices continue to normalize despite ongoing challenges

Gordian’s most recent Quarterly Construction Cost Insights Report for Q4 2023 describes an industry still attempting to recover from the impact of COVID. This was complicated by inflation, weather, and geopolitical factors that resulted in widespread pricing adjustments throughout the construction materials industries.

Hotel Facilities | Jan 22, 2024

U.S. hotel construction is booming, with a record-high 5,964 projects in the pipeline

The hotel construction pipeline hit record project counts at Q4, with the addition of 260 projects and 21,287 rooms over last quarter, according to Lodging Econometrics.

Modular Building | Jan 19, 2024

Virginia is first state to adopt ICC/MBI offsite construction standards

Virginia recently became the first state to adopt International Code Council/Modular Building Institute off-site construction standards.

Mixed-Use | Jan 19, 2024

Trademark secures financing to develop Fort Worth multifamily community

National real estate developer, investor, and operator, Trademark Property Company, has closed on the land and secured the financing for The Vickery, a multifamily-led mixed-use community located on five acres at W. Vickery Boulevard and Hemphill Street overlooking Downtown Fort Worth.