When The Shed, a $435 million arts, education, and entertainment center in New York City, had its grand opening in the spring of 2019, it attracted attention for its 115-foot-tall moveable canopy that, when fully opened, adds 17,000 sf of light-, sound-, and temperature-controlled multipurpose space; and when fully retracted into the 200,000-sf building uncovers an open-air public plaza.

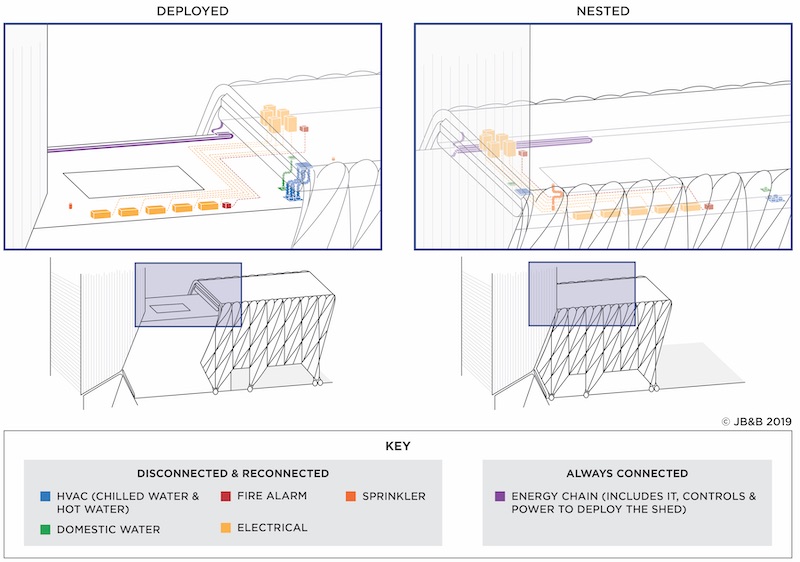

What’s less appreciated, perhaps, by The Shed’s visitors, students, and performers is its electrical interconnection system that powers the building’s nested and deployed positions, and that must be disconnected and connected every time the canopy opens and closes.

“I don’t know of any other moveable building in the world that’s like this. We built it like a Swiss watch,” says Mark Torre, PE, LEED AP, Managing Partner with Jaros, Baum and Bolles (JB&B), the project’s MEP and fire protection consultant.

As originally designed by Diller, Scofidio + Renfro in collaboration with Rockwell Group, The Shed had two moveable features, each of which would have needed to be heated and cooled. (Torre says that design was scotched as being too complex and costly.)

The project team also thought it would have more space below The Shed for its mechanical room, but that didn’t work out, either. At one point, there was some thought given to running air conditioning ducts through manholes, but that idea was rejected because the system would have cooled only about 15% of the performance space.

So the 850,000 lbs of mechanicals—including the building maintenance unit, HVAC, plumbing, conduit, and other equipment—are above the canopy’s lighting rig. Scott Lomax, Senior Principal with Thornton Tomasetti, the project’s structural engineer, says that based on The Shed’s current programming needs, the project team predicted that the 6.1 million-lb canopy will retract about once per month through the life of the building.

See Also: The Shed arts center includes a massive, telescoping outer shell

To facilitate that movement, JB&B created attachment points (both nested and not), which Torre says required precise installation of systems that would be disconnected and reconnected as needed. These systems include normal utility power, legally required standby power, emergency power, fire alarm power and communications, chilled and hot water supply and return, domestic water makeup (which addresses evaporation and maintenance issues), and sprinkler service for the mechanical deck above the event space. The connect/disconnect are performed manually and take about six hours to complete, says Torre. The Shed services that remain connected through the “power chain” include the building management system’s communications and power, information technology, and power for the canopy’s motors and kinetics control system.

Torre notes that nearly all of The Shed’s mechanical systems (for the moveable portions) required variances. These included the energy chain power (for permanent flexible power wiring) as well as the methods for connecting and disconnecting the moveable Shed.

Related Stories

Great Solutions | Sep 14, 2017

Hydraulic underground boardwalk and gangway system reunites the public with the coastline in Istanbul

The bespoke system is part of a master plan by Dror and Gensler that creates the world’s first underground cruise operation.

Great Solutions | Aug 14, 2017

Transmogrifying ‘E ink,’ energy-harvesting paint remove the ‘fiction’ from ‘science fiction’

These materials can turn an ordinary wall into dynamic real estate.

Great Solutions | Jul 12, 2017

The writing on the wall: Maker spaces encourage students to take an active role

Maker spaces, dry-erase walls, and flexible furniture highlight Kinkaid’s new Learning Center.

Great Solutions | Jun 6, 2017

Good vibrations: Portable tuned mass damper provides lightweight, cost-effective way to reduce structural vibrations

Developed by a team at Virginia Tech, the PTMD has been shown to reduce vibrations by as much as 75%.

Great Solutions | May 5, 2017

No nails necessary: Framing system comes together with steel zip ties and screws

Clemson University’s School of Architecture develops a patent-pending construction method that is gaining attention for its potential use in rapid, low-tech sustainable housing.

Great Solutions | Apr 6, 2017

Phone booths for the 21st century

Spotting a phone booth on a public street may not become any less rare, but they may soon become fixtures in the modern office.

Great Solutions | Mar 8, 2017

Pop-out balcony is a breath of fresh air for stuffy hotel rooms and apartments

In less than one minute, Bloomframe transforms from an insulated picture window to an open balcony.

Great Solutions | Feb 3, 2017

Drone-based hospitality concept looks to make nomads of us all

Driftscape could take the resort industry to places no hotel has ventured before.

AEC Tech | Sep 6, 2016

Innovation intervention: How AEC firms are driving growth through R&D programs

AEC firms are taking a page from the tech industry, by infusing a deep commitment to innovation and disruption into their cultural DNA.

Great Solutions | Aug 23, 2016

GBBN designers take on wellness research

In a new research paper, three healthcare specialists present factors that contribute to a psychological state that is receptive to healing.