When The Shed, a $435 million arts, education, and entertainment center in New York City, had its grand opening in the spring of 2019, it attracted attention for its 115-foot-tall moveable canopy that, when fully opened, adds 17,000 sf of light-, sound-, and temperature-controlled multipurpose space; and when fully retracted into the 200,000-sf building uncovers an open-air public plaza.

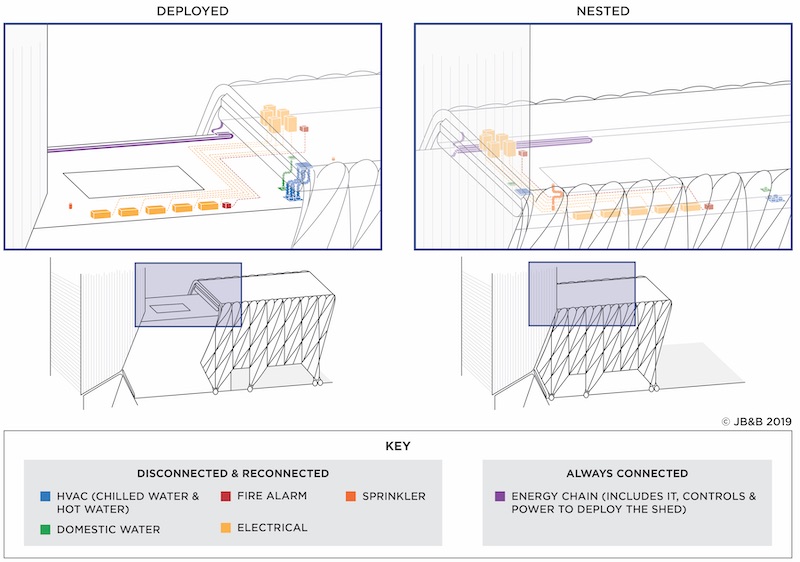

What’s less appreciated, perhaps, by The Shed’s visitors, students, and performers is its electrical interconnection system that powers the building’s nested and deployed positions, and that must be disconnected and connected every time the canopy opens and closes.

“I don’t know of any other moveable building in the world that’s like this. We built it like a Swiss watch,” says Mark Torre, PE, LEED AP, Managing Partner with Jaros, Baum and Bolles (JB&B), the project’s MEP and fire protection consultant.

As originally designed by Diller, Scofidio + Renfro in collaboration with Rockwell Group, The Shed had two moveable features, each of which would have needed to be heated and cooled. (Torre says that design was scotched as being too complex and costly.)

The project team also thought it would have more space below The Shed for its mechanical room, but that didn’t work out, either. At one point, there was some thought given to running air conditioning ducts through manholes, but that idea was rejected because the system would have cooled only about 15% of the performance space.

So the 850,000 lbs of mechanicals—including the building maintenance unit, HVAC, plumbing, conduit, and other equipment—are above the canopy’s lighting rig. Scott Lomax, Senior Principal with Thornton Tomasetti, the project’s structural engineer, says that based on The Shed’s current programming needs, the project team predicted that the 6.1 million-lb canopy will retract about once per month through the life of the building.

See Also: The Shed arts center includes a massive, telescoping outer shell

To facilitate that movement, JB&B created attachment points (both nested and not), which Torre says required precise installation of systems that would be disconnected and reconnected as needed. These systems include normal utility power, legally required standby power, emergency power, fire alarm power and communications, chilled and hot water supply and return, domestic water makeup (which addresses evaporation and maintenance issues), and sprinkler service for the mechanical deck above the event space. The connect/disconnect are performed manually and take about six hours to complete, says Torre. The Shed services that remain connected through the “power chain” include the building management system’s communications and power, information technology, and power for the canopy’s motors and kinetics control system.

Torre notes that nearly all of The Shed’s mechanical systems (for the moveable portions) required variances. These included the energy chain power (for permanent flexible power wiring) as well as the methods for connecting and disconnecting the moveable Shed.

Related Stories

Great Solutions | Aug 23, 2016

Visual energy model database demystifies net-zero design

Diamond Schmitt Architects’ ecoMetrics tool allows its designers to quickly analyze solutions based on models from 44 LEED-certified projects.

Great Solutions | Aug 23, 2016

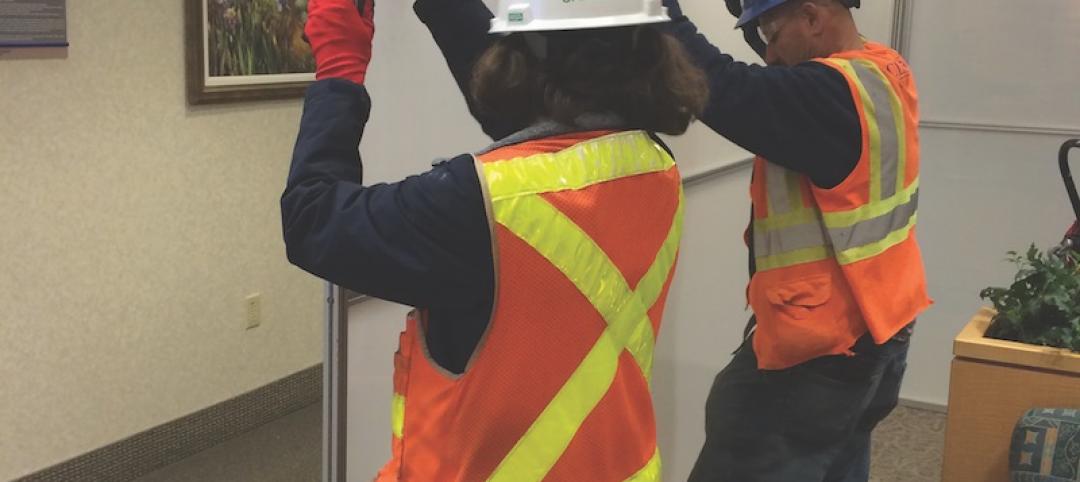

Reusable infection control barriers ease hospital renovation

Clark Construction Group pilots the Edge Guard system on the Fair Oaks (Va.) Hospital reconstruction project.

Great Solutions | Aug 23, 2016

Novel construction approach speeds K-12 school projects

The Folia system uses pre-engineered components to deliver school buildings at 20% less cost.

Great Solutions | Aug 23, 2016

Mobile emergency room arrives just in time for Alabama hospital

The MED-1 Mobile Hospital Unit serves as a lower-cost solution during construction of new ED.

Great Solutions | Aug 23, 2016

Durable coffeemaker brings a bit of comfort to job sites

The CoffeeBoxx is lightweight rust proof, dust proof, water resistant, and ultra durable.

Great Solutions | Aug 23, 2016

Reclaimed wood paneling adds color to retail and hospitality projects

Colorburst panels are available in four stock options—Robin Egg Blue, Viridian Green, Haute Pink, and Cascade White—as well as custom colors.

Great Solutions | Aug 23, 2016

Biophilic pods beat the shade when it comes to outdoor cooling

The Xylem concept by CallisonRTKL regulates outdoor thermal comfort through shading, air movement, water circulation, and a vegetated roof.

Great Solutions | Aug 23, 2016

Mini-grant R&D program pays off in a big way for AE firm

Created through funding from Little’s LaceUp program, the Center for Building Performance has helped the design firm win 14 new jobs since its inception.

Great Solutions | Aug 23, 2016

At Beyer Blinder Belle everyone’s seeing RED

The firm’s R&D initiative inspires its designers to develop ideas that could positively disrupt the practice.

Great Solutions | Aug 23, 2016

Virtual care facility serves remote patients, may reduce readmissions

Mercy’s new high-tech medical center equips its medical professionals to deliver care at the bedside of patients anywhere.