When The Shed, a $435 million arts, education, and entertainment center in New York City, had its grand opening in the spring of 2019, it attracted attention for its 115-foot-tall moveable canopy that, when fully opened, adds 17,000 sf of light-, sound-, and temperature-controlled multipurpose space; and when fully retracted into the 200,000-sf building uncovers an open-air public plaza.

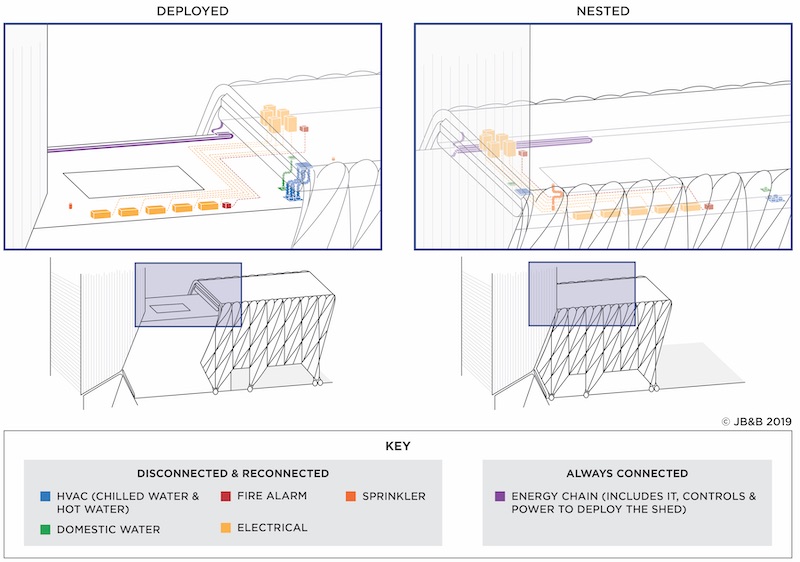

What’s less appreciated, perhaps, by The Shed’s visitors, students, and performers is its electrical interconnection system that powers the building’s nested and deployed positions, and that must be disconnected and connected every time the canopy opens and closes.

“I don’t know of any other moveable building in the world that’s like this. We built it like a Swiss watch,” says Mark Torre, PE, LEED AP, Managing Partner with Jaros, Baum and Bolles (JB&B), the project’s MEP and fire protection consultant.

As originally designed by Diller, Scofidio + Renfro in collaboration with Rockwell Group, The Shed had two moveable features, each of which would have needed to be heated and cooled. (Torre says that design was scotched as being too complex and costly.)

The project team also thought it would have more space below The Shed for its mechanical room, but that didn’t work out, either. At one point, there was some thought given to running air conditioning ducts through manholes, but that idea was rejected because the system would have cooled only about 15% of the performance space.

So the 850,000 lbs of mechanicals—including the building maintenance unit, HVAC, plumbing, conduit, and other equipment—are above the canopy’s lighting rig. Scott Lomax, Senior Principal with Thornton Tomasetti, the project’s structural engineer, says that based on The Shed’s current programming needs, the project team predicted that the 6.1 million-lb canopy will retract about once per month through the life of the building.

See Also: The Shed arts center includes a massive, telescoping outer shell

To facilitate that movement, JB&B created attachment points (both nested and not), which Torre says required precise installation of systems that would be disconnected and reconnected as needed. These systems include normal utility power, legally required standby power, emergency power, fire alarm power and communications, chilled and hot water supply and return, domestic water makeup (which addresses evaporation and maintenance issues), and sprinkler service for the mechanical deck above the event space. The connect/disconnect are performed manually and take about six hours to complete, says Torre. The Shed services that remain connected through the “power chain” include the building management system’s communications and power, information technology, and power for the canopy’s motors and kinetics control system.

Torre notes that nearly all of The Shed’s mechanical systems (for the moveable portions) required variances. These included the energy chain power (for permanent flexible power wiring) as well as the methods for connecting and disconnecting the moveable Shed.

Related Stories

Great Solutions | Jul 9, 2021

MojoDesk creates a new solution for managing open office distractions

The MojoDome allows for a private work space while also maintaining a collaborative environment.

Great Solutions | Mar 18, 2021

Follow the leader: New following technology better equips robots for the jobsite

New proof-of-concept from Piaggio Fast Forward and Trimble enables robots and machines to follow humans.

Great Solutions | Feb 11, 2021

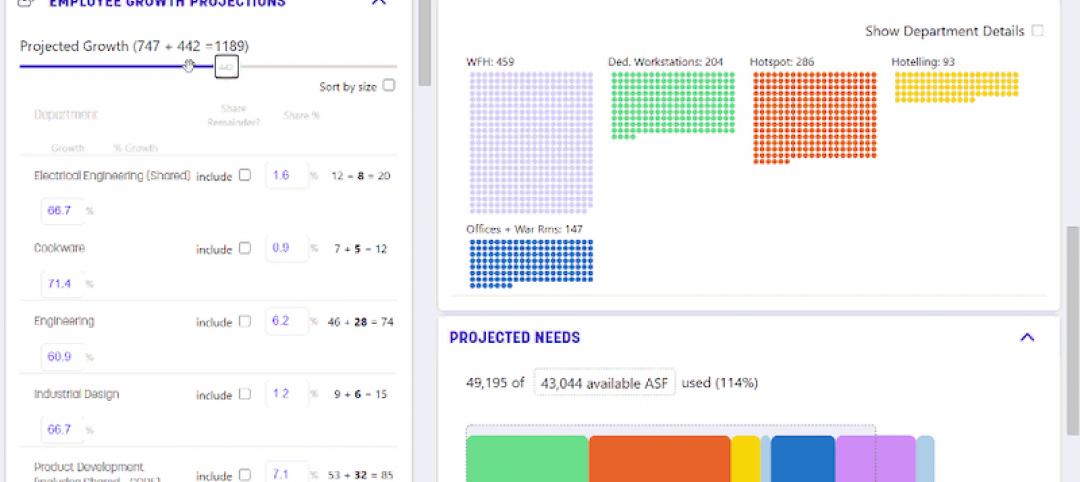

Simplifying the return to the office

A new web-based tool from Sasaki takes the guesswork out of heading back to the workplace.

Great Solutions | Oct 6, 2020

Could water-filled windows help buildings save energy?

New research shows how water-filled glass could help heat and cool buildings.

Great Solutions | Aug 10, 2020

From lobby to penthouse, elevators can be a 100% touch-free experience

The Toe-To-Go elevator system allows riders to operate the elevator entirely with their feet.

Great Solutions | Jul 13, 2020

Essential protection for businesses

Custom protective barriers help keep essential business employees safe.

Great Solutions | Apr 13, 2020

Family workstations highlight the new Fairfield Area Library

The workstations are the perfect remedy for squirming, restless children and toddlers.

Great Solutions | Dec 18, 2019

Robot uprising

Thyssenkrupp’s robotics interface platform helps robots use elevators like humans.

Great Solutions | Nov 12, 2019

Skanska designs personal protective equipment tailor-made for the female workforce

A safety vest is the first piece of equipment to undergo an update.

Great Solutions | Oct 3, 2019

REEF Technology wants to turn parking facilities into urban mobility hubs

The company currently operates 4,500 parking lots in 25 markets across North America.