1. UNDERLAYMENT SYSTEM DESIGNED TO SAVE TIME, MONEY ON SLAB WORK

Swedish Hospital and Medical Office Building, Issaquah, Wash., is a 600,000-sf campus developed by Hammes Company, with architect Collins Woerman and contractor Sellen Construction leading the Building Team. The project was completed ahead of schedule and nearly $35 million under budget through a combination of methods, including heavy use of Lean principles, BIM, and integrated delivery. One result of the teamwork was the choice of the SUPERCAP system to cap the concrete base slab, instead of using a traditional trowel-applied finish. The system combines a Greenguard-certified, low-alkali, self-leveling cement-base technology with a computer-controlled pump truck. At Swedish Hospital, the system eliminated concerns about flatness inherent to concrete slab work with structural steel buildings. Sellen placed about 20,000 sf/day of concrete, compared with 15,000 sf/day using conventional troweling. LATICRETE

2. TEXAS STUDENTS MOVE IN FASTER WITH RAPID-DRYING CONCRETE

The original schedule for Billy Earl Dade Middle School, a replacement school for the Dallas Independent School District, called for a 14-month construction period. When officials asked that the schedule be cut to 10 months so students could move in for the fall 2013 term, the Building Team knew concrete drying posed a potential problem. Aridus Rapid Drying Concrete, a ready-mix formulated to help prevent moisture-related flooring failures, was selected for its combination of fast drying time, high early strength, compressive strength, and low permeability. The project required 20,000 cubic yards of concrete, including 5,000 cubic yards of Aridus used to cover 120,000 sf of floors. Crews were able to install final flooring 21 days after the concrete was poured, compared with a typical drying time of at least four months. On the Building Team: Satterfield & Pontikes Construction (GC), Redi-Mix Concrete (concrete supplier), and KAI Texas (architect). U.S. Concrete

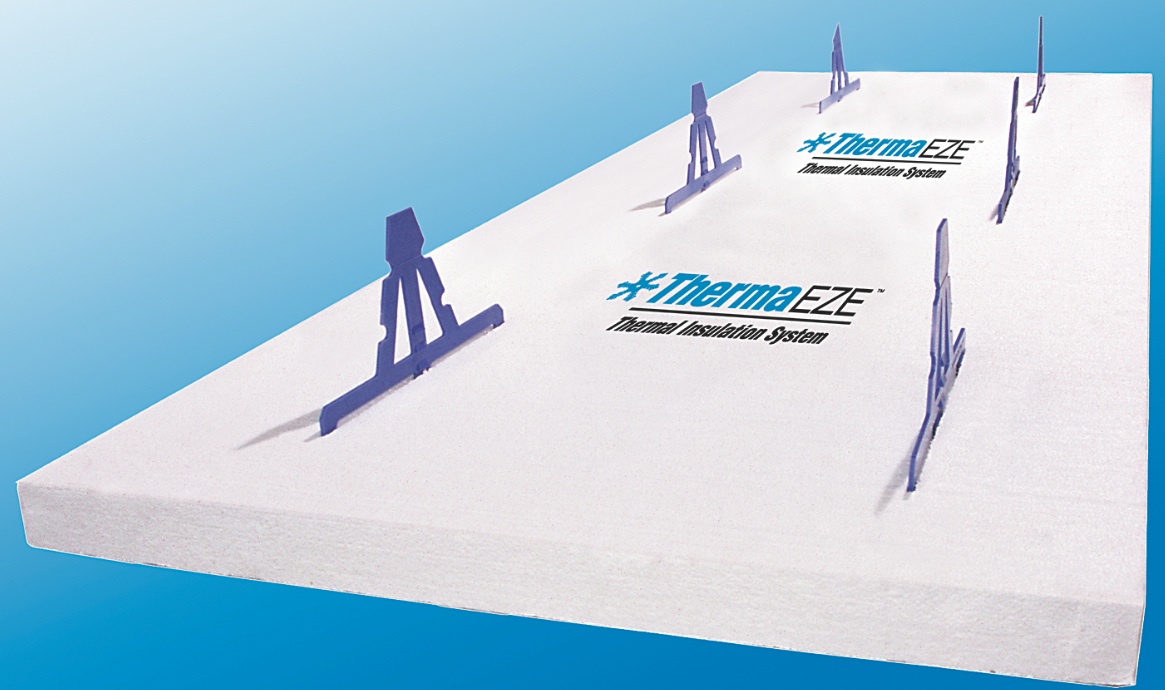

3. THERMAL INSULATION SYSTEM TAILORED TO POURED CONCRETE WALL CONSTRUCTION

ThermaEZE thermal insulation works with poured concrete walls—including foundation walls—for better insulation than conventional poured concrete, according to the manufacturer. The system consists of panels of expanded polystyrene foam, placed within the wall forms before the pour and held in place by a patented web structure that becomes embedded in the concrete. The resulting walls thus consist of a concrete layer and an attached insulation panel, with fastening strips on the exposed face to facilitate application of drywall or other finish materials. Depending on the thickness of the concrete, R-values range from 9.6 to 11.7. Panels are termite-resistant, odor-free, and contain no CFCs, HCFCs, HFCs, or formaldehyde. The UL-approved system is IECC code-compliant for foundation walls, and meets ASTM C578 Type 1 and ICC-ES EG239 requirements for below-grade use. North American Specialty Products

4. OPTIMIZATION SERVICE ADDS GREEN SPIN TO ONE WORLD TRADE CENTER CONSTRUCTION

In addition to sending a symbolic message of strength and freedom, One World Trade Center in New York City was designed to be an example of sustainability. The Port Authority of New York/New Jersey imposed strict requirements, including replacing a high percentage of portland cement with recycled materials. BASF Construction Chemicals’ Green Sense optimization service helped the Building Team, including concrete contractor Collavino Construction and concrete producer Eastern Concrete Materials, create mixes with appropriate compressive strength for the 1,776-foot skyscraper. The mix replaced 71% of the portland cement that would have been required in a conventional mix with recycled materials, non-cementitious fillers, and specialized admixtures to exceed performance targets specified by the stakeholders. The first 40 floors required 38,000 cubic yards of a special mix, providing compressive strength of at least 12,000 psi. BASF estimates that 25.4 million in kWh savings will be produced over the project’s life cycle in connection with the mix, as well as reductions in fossil fuel and greenhouse gas production, rain acidification potential, water, and solid waste. BASF Corporation

5. BIO-BASED COMPOSITE COMBINES HEMP AND LIME FOR HIGH PERFORMANCE

Tradical Hemcrete, developed in the U.K. by Lime Technology, incorporates hemp shiv (the woody core of industrial hemp) and a lime-based binder, Tradical HB. The resulting composite exhibits good thermal insulation and excellent thermal inertia, according to the manufacturer, creating environments that need minimal heating or cooling. The material has negative embodied carbon because CO2 that is captured by hemp as it grows is ultimately sequestered within the Hemcrete. Several design and construction methods are appropriate, including direct application to timber-framed structures and use with a rainscreen system. Because proper on-site drying can be tricky, the company recently developed systems that incorporate the material in factory-made panels, including Hembuild (for low-rise buildings) and Hemclad (for large-scale buildings with a primary structural frame). American Lime Technology

6. DRYING TIME FOR CONCRETE REDUCED BY POLYASPARTIC COATINGS

Rapid-curing polyaspartic coatings using raw materials from Bayer MaterialScience are designed for faster productivity without sacrificing high performance or durability. Usable for both metal and concrete surfaces, the coatings resist damage from ultraviolet light, chemical spills, and abrasion. They have ultra-low VOC emissions and high color stability and cleanability, according to the manufacturer. Formulations offer a fast curing time, with a typical start-to-finish cycle that fits within an eight-hour work day. Coatings made with polyaspartic esters can be applied at temperatures below 50°F and in high-humidity environments, extending the application season. The coatings can be applied over stains for attractive effects. Appropriate commercial projects include hotels, restaurants, retail space, healthcare, and other facilities with concrete floors. Bayer MaterialScience

7. CONCRETE ROOF TILES EAT SMOG, COURTESY OF BONDED TITANIUM DIOXIDE

BoralPure Smog-Eating Tile, recipient of Popular Mechanics’ Breakthrough Award, removes nitrogen oxides from the atmosphere to improve environmental quality. The tiles include the photocatalyst titanium dioxide, which oxidizes with vehicle-emitted NOx and removes it from the atmosphere. The benign precipitate resulting from the chemical reaction washes away in the rain. The technology also uses naturally occurring UV light to help break down organic substances that can occur on roofs, such as mold and algae. Additional benefits cited by the manufacturer include high thermal mass, emissivity, and reflectivity, and an insulating air space between the tile and the roof deck. At the end of their service life, the tiles can be recycled for new structures or roadways. Boral Roofing

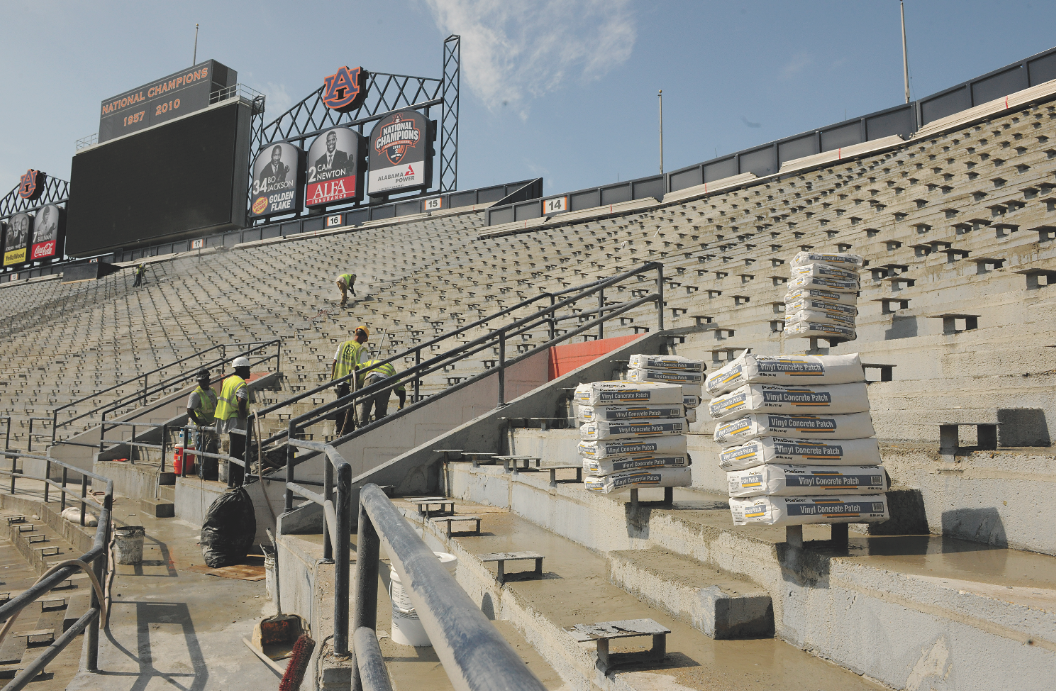

8. PRIMER-PATCH COMBO SOLVES WATER PROBLEM AT AUBURN STADIUM

Auburn University’s Jordan-Hare stadium, home of the football Tigers, needed repairs recently when settling of precast concrete risers caused cyclical flooding. Water pooled on the floors of the risers every time it rained, increasing the risk of concrete damage and forcing fans to cope with the puddles. Contractor Southeast Restoration & Fireproofing applied ProSpec Level Set Epoxy Primer with sand broadcast to address the water problem in hard-to-bond areas where the existing coating could not be removed. This created a strong bonding surface for a mix of ProSpec Vinyl Concrete Patch and B-730 Mortar/Acrylic Additive. The product was feather-edge sloped over the concrete flooring to fill in areas where pooling had typically occurred. The fix will help improve the longevity of the stadium and keep patrons’ feet drier during games. ProSpec / Bonsal American

9. TREATMENTS IMPROVE DENSITY WHILE MAKING SURFACES MORE ATTRACTIVE

Two products in PROSOCO’s Consolideck line are designed to improve the density and surface appearance of concrete. Consolideck LS features a lower viscosity and more highly reactive silicates than conventional sodium or potassium silicate hardeners. These characteristics help the formula penetrate more deeply into the surface. Higher reactivity aids hardening without the aggressive scrubbing and rinsing needed with conventional hardeners, according to the manufacturer. Consolideck LSGuard is a high-gloss sealer, hardener, and densifier that further increases sheen, hardness, and stain resistance of floors treated with Consolideck LS. It produces a high-gloss finish that maximizes light reflectance, eliminating the need for floor waxes, liquid polishers, and conventional resin coatings. PROSOCO (Image: Chris Robertson Photography)

Related Stories

Architects | Mar 5, 2024

Riken Yamamoto wins 2024 Pritzker Architecture Prize

The Pritzker Architecture Prize announces Riken Yamamoto, of Yokohama, Japan, as the 2024 Laureate of the Pritzker Architecture Prize, the award that is regarded internationally as architecture’s highest honor.

Office Buildings | Mar 5, 2024

Former McDonald’s headquarters transformed into modern office building for Ace Hardware

In Oak Brook, Ill., about 15 miles west of downtown Chicago, McDonald’s former corporate headquarters has been transformed into a modern office building for its new tenant, Ace Hardware. Now for the first time, Ace Hardware can bring 1,700 employees from three facilities under one roof.

Green | Mar 5, 2024

New York City’s Green Economy Action Plan aims for building decarbonization

New York City’s recently revealed Green Economy Action Plan includes the goals of the decarbonization of buildings and developing a renewable energy system. The ambitious plan includes enabling low-carbon alternatives in the transportation sector and boosting green industries, aiming to create more than 12,000 green economy apprenticeships by 2040.

Lighting | Mar 4, 2024

Illuminating your path to energy efficiency

Design Collaborative's Kelsey Rowe, PE, CLD, shares some tools, resources, and next steps to guide you through the process of lighting design.

MFPRO+ News | Mar 1, 2024

Housing affordability, speed of construction are top of mind for multifamily architecture and construction firms

The 2023 Multifamily Giants get creative to solve the affordability crisis, while helping their developer clients build faster and more economically.

Multifamily Housing | Feb 29, 2024

Manny Gonzalez, FAIA, inducted into Best in American Living Awards Hall of Fame

Manny Gonzalez, FAIA, has been inducted into the BALA Hall of Fame.

K-12 Schools | Feb 29, 2024

Average age of U.S. school buildings is just under 50 years

The average age of a main instructional school building in the United States is 49 years, according to a survey by the National Center for Education Statistics (NCES). About 38% of schools were built before 1970. Roughly half of the schools surveyed have undergone a major building renovation or addition.

MFPRO+ Research | Feb 28, 2024

New download: BD+C's 2023 Multifamily Amenities report

New research from Building Design+Construction and Multifamily Pro+ highlights the 127 top amenities that developers, property owners, architects, contractors, and builders are providing in today’s apartment, condominium, student housing, and senior living communities.

AEC Tech | Feb 28, 2024

How to harness LIDAR and BIM technology for precise building data, equipment needs

By following the Scan to Point Cloud + Point Cloud to BIM process, organizations can leverage the power of LIDAR and BIM technology at the same time. This optimizes the documentation of existing building conditions, functions, and equipment needs as a current condition and as a starting point for future physical plant expansion projects.

Data Centers | Feb 28, 2024

What’s next for data center design in 2024

Nuclear power, direct-to-chip liquid cooling, and data centers as learning destinations are among the emerging design trends in the data center sector, according to Scott Hays, Sector Leader, Sustainable Design, with HED.