On any given night, more than 500,000 Americans are homeless. Of that total, more than one-third of those homeless—35%—is unsheltered. And 47% of all unsheltered homeless live in California, which is four times higher than the state’s 12% share of the U.S. population.

Those estimates come from “The State of Homelessness in America,” which the White House’s Council of Economic Advisors released in September. That report notes that in the last two years, homelessness in Los Angeles alone had risen by 12% to more than 59,000 people. An estimated 44,000 of L.A.’s homeless eschew its shelter system, often preferring instead to live in outdoor tents that offer them more privacy and security.

Los Angeles isn’t oblivious to this situation. Proposition HHH, approved by voters in 2016, allocates $1.2 billion to build thousands of “supportive housing” units over the next decade. Los Angeles Mayor Eric Garcetti has also initiated a plan called A Bridge Home, which would help the homeless get into temporary housing in their preferred neighborhoods until they can be connected with a permanent home. The Mayor’s budget includes in excess of $460 million for supportive housing, bridge housing, and services. The state kicked in another $219 million this year.

Los Angeles is committed to creating 1,600 new units for the homeless by July 2020, and is considering a number of options, including DOME, a modular, unitized system that Perkins and Will designed specifically for interim and emergency housing.

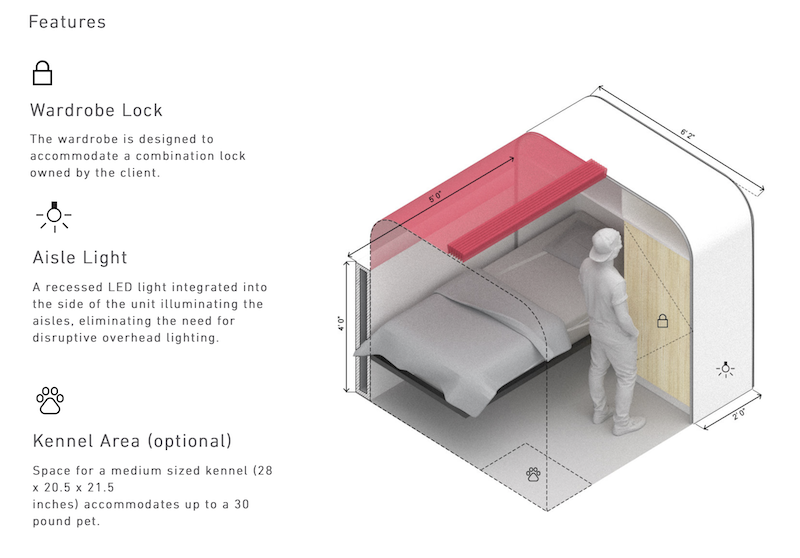

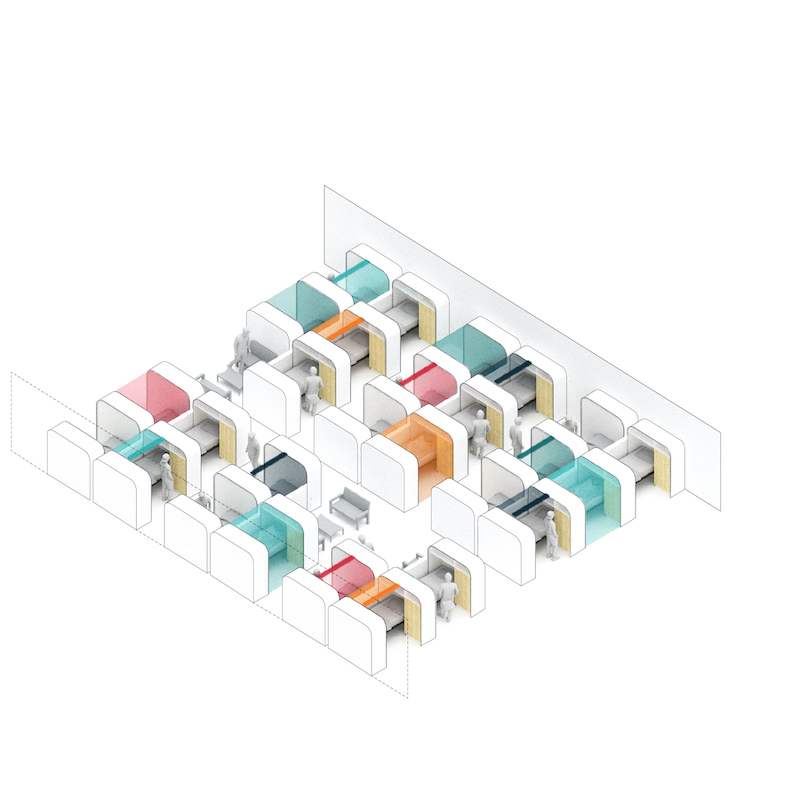

The unit, which ranges from 47 to 52 sf, includes a bed with room for storage underneath, a lockable wardrobe, partitions, access to an electrical outlet, and an optional fabric canopy that can be pulled down for additional privacy. A person can stand inside DOME. And the design allows for an optional medium-sized kennel that can accommodate a pet up to 30 lbs.

DOME units' installation maximizes space.

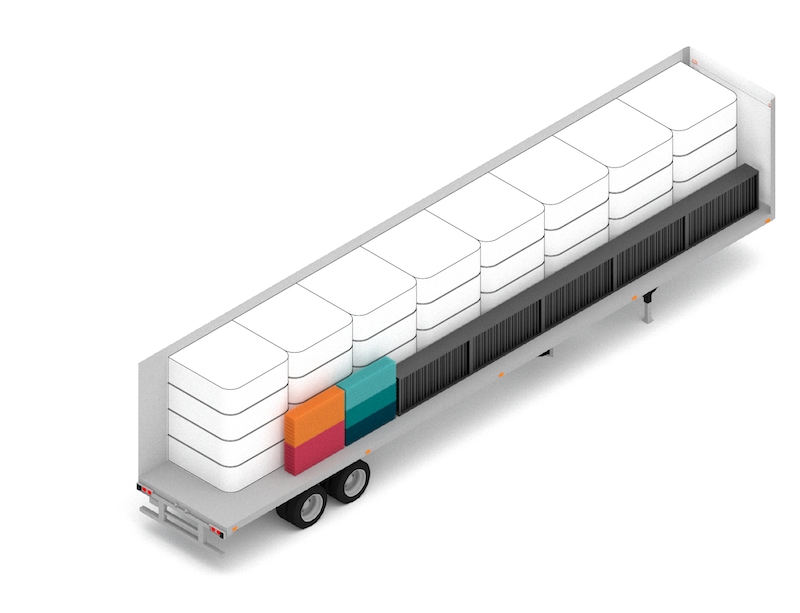

Yan Krymsky, design director of Perkins and Will's Los Angeles studio, calls DOME “a sleeping cabinet.” DOME’s microsite provides details about the unit and its installation, which slots together onsite and is collapsible; 32 units could fit onto a 53-ft-long trailer. P&W estimates DOME’s cost at $4,749 per unit.

A prototype of DOME, built by Shield Casework in Kansas City, Mo., has been installed in the Los Angeles Architecture & Design Art Museum, where interested parties can evaluate its design, construction and utility, and offer comments.

Krymsky says that P&W has also been talking with shelter operators such as the Salvation Army and People Assisting the Homeless (PATH) to gauge interest in DOME and to see if they are willing to test it out. DOME’s design is flexible enough to bend to different operators philosophies about partitions (some like them, others don’t, for security reasons). The prototype could also be made bigger (some operators prefer longer beds, for example.)

P&W got interested in this project when it was retained by the city to do research on interim housing. As such, it learned that this kind of housing typically provides extended-stay shelter, anywhere from six months to two years. P&W also learned that there wasn’t much out there that could provide bridge housing. “For us, that’s unusual in other typologies,” says Krymsky.

Shield Casework, a five-year-old company, specializes in making products using acrylic solid surface. Its two primary markets are healthcare and sports, for which it prefabricates everything from headwalls to custom lockers.

32 DOME units can be shipped on a single 53-ft trailer.

Stephen Hopkins, Shield’s president, says that he and Krymsky had worked on previous projects, including a dorm-pod concept for the University of Utah that didn’t get built for code reasons but set the stage for the two companies’ alliance on DOME.

“For us, the challenge was how do we hone the design to its basic components” so that it could be produced simply and efficiently, says Hopkins, who is an architect.

Neither he nor Krymsky see DOME as a silver bullet for solving homelessness, given the magnitude of the problem. “It’s a Band-Aid, but one we’re happy to provide,” says Hopkins. If demand for DOME were to take off, Shield has the capacity to produce 1,000 or so units over a six-month period without disrupting its other orders.

Krymsky anticipates high interest in DOME, not only in L.A. but possibly from other cities desperately seeking housing options. Perkins + Will is also considering other housing designs, such as tiny houses (which California codes currently don’t allow). “Our frustration [with tiny houses] is that their pricing is total confusion,” with the lowest-priced model with electricity he’s seen costing around $20,000.

Related Stories

| Apr 25, 2014

A radiant barrier FAQ: Everything you wanted to know but were afraid to ask

There are many examples of materials developed for the space program making their way into everyday life and radiant barriers are just that. SPONSORED CONTENT

| Apr 23, 2014

Developers change gears at Atlantic Yards after high-rise modular proves difficult

At 32 stories, the B2 residential tower at Atlantic Yards has been widely lauded as a bellwether for modular construction. But only five floors have been completed in 18 months.

| Apr 17, 2014

6 details that can throw off your schedule

In 1997, Apple told us to “Think Different.” So we did. We thought about what could happen if the world went mobile, if information was boundless, if we could carry our office in our back pocket. We’ve grown to love different and to expect change. And when it comes to Apple products, that’s not such a bad thing. When it comes to your building order, however, it’s not nearly as appealing.

| Apr 9, 2014

Steel decks: 11 tips for their proper use | BD+C

Building Teams have been using steel decks with proven success for 75 years. Building Design+Construction consulted with technical experts from the Steel Deck Institute and the deck manufacturing industry for their advice on how best to use steel decking.

| Apr 2, 2014

8 tips for avoiding thermal bridges in window applications

Aligning thermal breaks and applying air barriers are among the top design and installation tricks recommended by building enclosure experts.

| Mar 31, 2014

Tips for creating a competitive bid using codes and loads

Landing a project feels like winning a prize, sort of like finding that forgotten $20 bill in the pocket of a pair of jeans you haven’t worn in a while. But living on the “chance” of winning a job isn’t a great way to pay your electric bill. So, how do you swing the chances in your favor?

| Mar 26, 2014

A sales and service showcase

High Plains Equipment, a Case IH dealership in Devils Lake, N.D., constructs a larger facility to better serve its customers.

| Mar 26, 2014

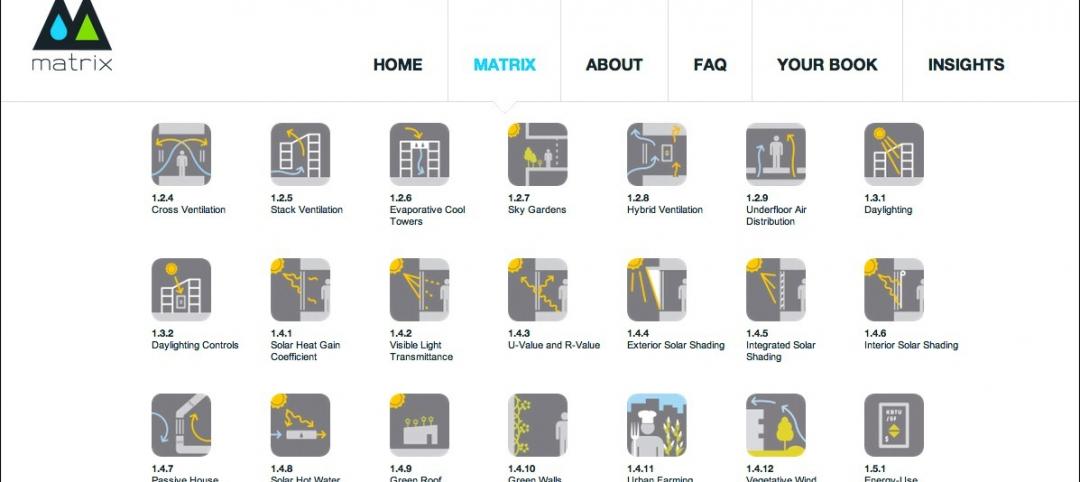

Callison launches sustainable design tool with 84 proven strategies

Hybrid ventilation, nighttime cooling, and fuel cell technology are among the dozens of sustainable design techniques profiled by Callison on its new website, Matrix.Callison.com.

| Mar 20, 2014

Common EIFS failures, and how to prevent them

Poor workmanship, impact damage, building movement, and incompatible or unsound substrate are among the major culprits of EIFS problems.

| Mar 19, 2014

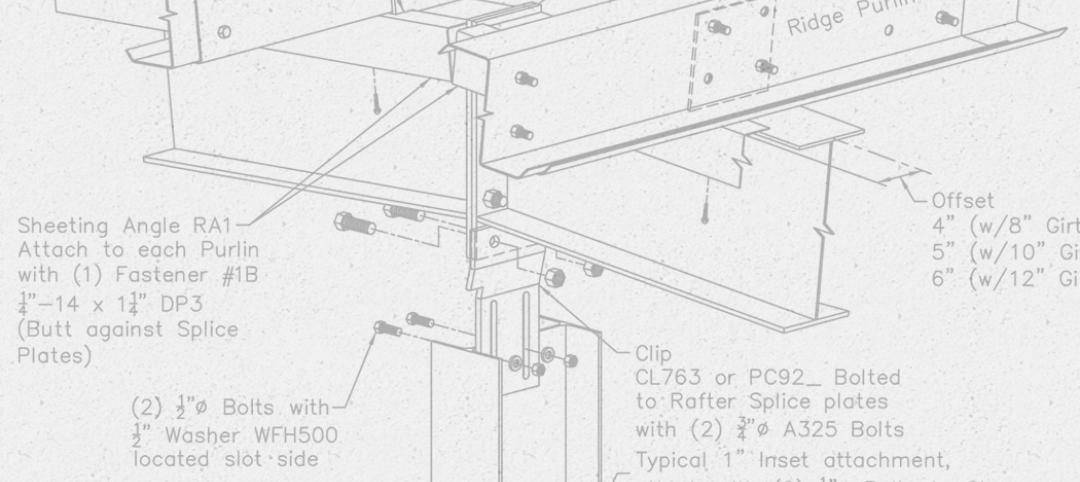

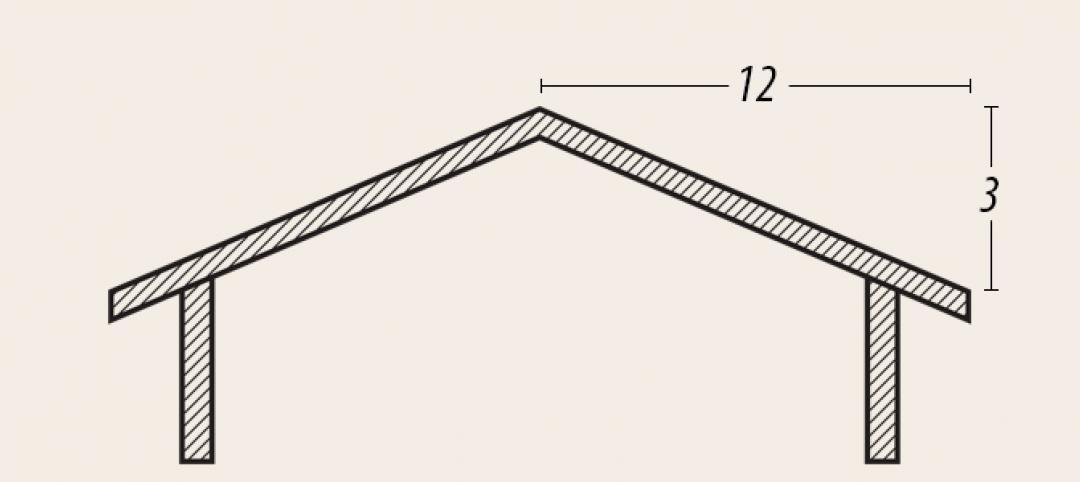

Frames: the biggest value engineering tip

In every aspect of a metal building, you can tweak the cost by adjusting the finish, panel thickness, and panel profile. These changes might make a few percentage points difference in the cost. Change the framing and you have the opportunity to affect 10-20 percent savings to the metal building portion of the project.