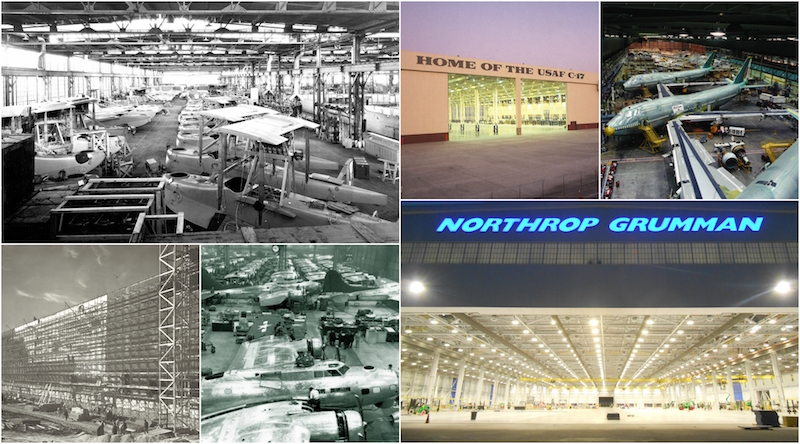

One hundred years ago, in 1916, The Austin Company began design and construction on its first of many aircraft assembly plants – the Curtiss Aeroplane and Motor Company plant in Buffalo, N.Y. This was just the beginning of a long list of innovative and successfully designed and constructed complex aircraft facilities that were often completed on a fast-track basis.

Austin’s many innovations along the way contributed to the success of our clients by enabling them to operate in more efficient environments, optimize the flexibility of their operations, and meet aggressive schedules. Austin architects, engineers, and constructors devised many innovations for the aviation sector since its inception, such as bi-fold hangar doors, metal-saving fiberglass wall panels for WWII bomber plants, induced airflows to improve ventilation in large plants, rolling work platforms to speed schedules, and more.

It is a proud history. We like to say that Austin has aviation in our DNA. While Samuel Austin was our founder and established high standards of ethics, values, and quality in our work, his son Wilbert was the innovator and visionary for aviation. Tragically, Wilbert died in a plane crash in Chicago in 1940, but by then, the DNA was well established.

Austin has held a formative role in this dynamic industry: airplanes, airports, engines, hangars, flight kitchens, cargo facilities, rockets, satellites. We have created these facilities in the U.S., Canada, Mexico, Italy, Australia, Greece, UK, Japan, and other locations.

In 100 years, manned flight has evolved from single engine bi-planes to supersonic travel, satellites, and space tourism. Design and construction has gone from pencils, linen, and slide rules to lasers, GPS, and integrated software platforms. Some things remain constant, however; a passion for this industry, an excitement toward how this market inspires and challenges us to innovate and achieve higher goals, and an appreciation of how this market drives us to technical excellence. This is where the DNA shows up, and it carries over into every market and industry we serve.

This historical timeline highlights some of the many aviation and aerospace projects Austin has completed over the past 100 years. It is a proud legacy that we carry on in our daily work.

Learn more at: http://www.theaustin.com/aerospace-defense-aviation

Related Stories

| Jul 7, 2014

7 emerging design trends in brick buildings

From wild architectural shapes to unique color blends and pattern arrangements, these projects demonstrate the design possibilities of brick.

| Jul 2, 2014

Emerging trends in commercial flooring

Rectangular tiles, digital graphic applications, the resurgence of terrazzo, and product transparency headline today’s commercial flooring trends.

| Jun 30, 2014

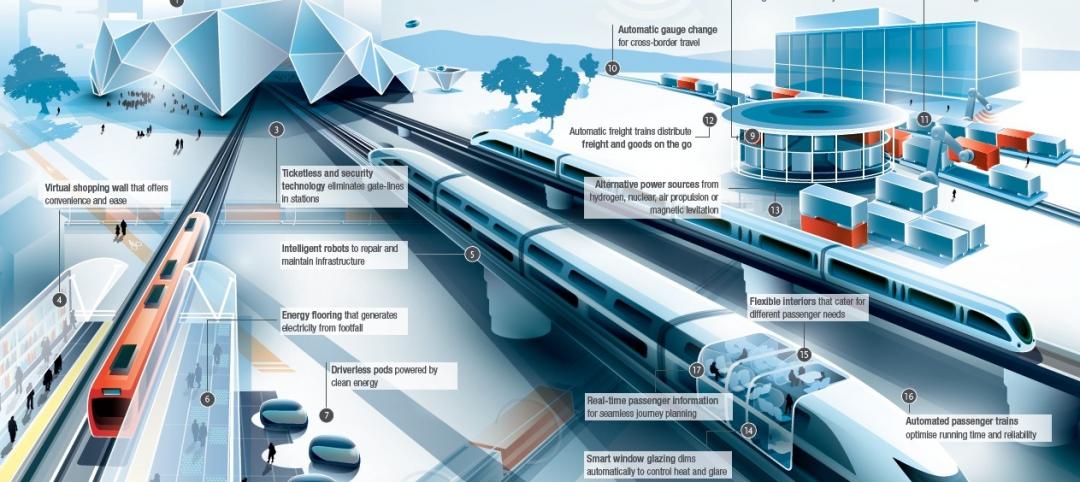

Arup's vision of the future of rail: driverless trains, maintenance drones, and automatic freight delivery

In its Future of Rail 2050 report, Arup reveals a vision of the future of rail travel in light of trends such as urban population growth, climate change, and emerging technologies.

| Jun 18, 2014

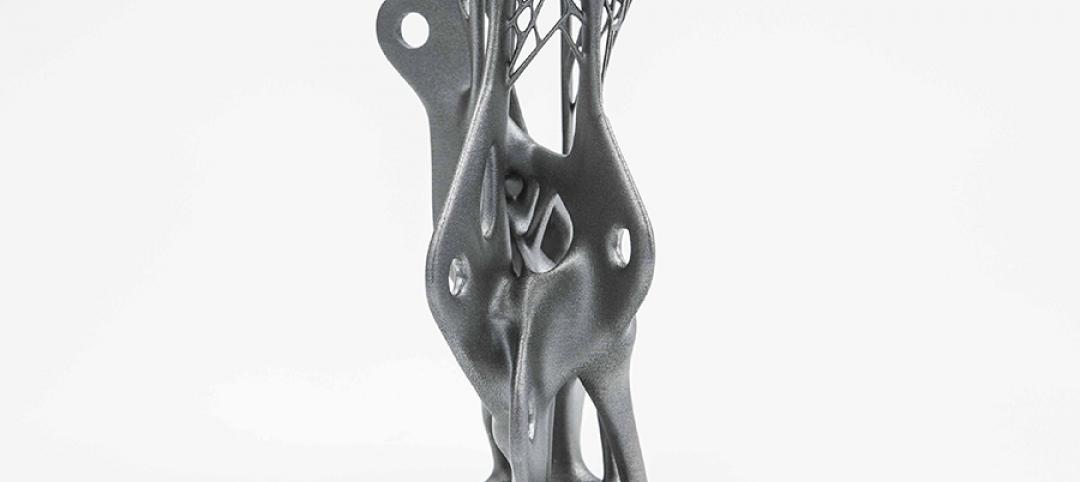

Arup uses 3D printing to fabricate one-of-a-kind structural steel components

The firm's research shows that 3D printing has the potential to reduce costs, cut waste, and slash the carbon footprint of the construction sector.

| Jun 12, 2014

Austrian university develops 'inflatable' concrete dome method

Constructing a concrete dome is a costly process, but this may change soon. A team from the Vienna University of Technology has developed a method that allows concrete domes to form with the use of air and steel cables instead of expensive, timber supporting structures.

| Jun 2, 2014

Parking structures group launches LEED-type program for parking garages

The Green Parking Council, an affiliate of the International Parking Institute, has launched the Green Garage Certification program, the parking industry equivalent of LEED certification.

| May 29, 2014

7 cost-effective ways to make U.S. infrastructure more resilient

Moving critical elements to higher ground and designing for longer lifespans are just some of the ways cities and governments can make infrastructure more resilient to natural disasters and climate change, writes Richard Cavallaro, President of Skanska USA Civil.

| May 23, 2014

Top interior design trends: Gensler, HOK, FXFOWLE, Mancini Duffy weigh in

Tech-friendly furniture, “live walls,” sit-stand desks, and circadian lighting are among the emerging trends identified by leading interior designers.

| May 20, 2014

Kinetic Architecture: New book explores innovations in active façades

The book, co-authored by Arup's Russell Fortmeyer, illustrates the various ways architects, consultants, and engineers approach energy and comfort by manipulating air, water, and light through the layers of passive and active building envelope systems.

| May 19, 2014

What can architects learn from nature’s 3.8 billion years of experience?

In a new report, HOK and Biomimicry 3.8 partnered to study how lessons from the temperate broadleaf forest biome, which houses many of the world’s largest population centers, can inform the design of the built environment.