AECOM, an integrated global infrastructure firm, and Project Frog, an innovator in advanced component buildings, are forming a partnership to address the increasing need for data centers. The Rapid Deployment Team will construct modular buildings with the quality and flexibility of traditional construction methods.

Project Frog leverages the integration of components from off-site manufacturing that are designed for shipping and rapid on-site installation. The Converge data center kit results in an accelerated construction schedule which materially increases the speed to market of a revenue-producing data center anywhere in the world.

For more than 25 years, AECOM has planned, designed, and constructed data centers and mission critical facilities around the world. The company has a deep knowledge of the data center market and expertise in the turnkey provision of data center facilities. AECOM provides solutions that allow simplified installation processes that enable future expansion with cost, time, and maintenance benefits.

With customizable solutions for small (1 MW) to large data centers (50+ MW), the AECOM and Project Frog Rapid Deployment Team streamlines data center development. The solution allows for consistent and scalable roll out globally.

Related Stories

| Apr 25, 2014

A radiant barrier FAQ: Everything you wanted to know but were afraid to ask

There are many examples of materials developed for the space program making their way into everyday life and radiant barriers are just that. SPONSORED CONTENT

| Apr 23, 2014

Developers change gears at Atlantic Yards after high-rise modular proves difficult

At 32 stories, the B2 residential tower at Atlantic Yards has been widely lauded as a bellwether for modular construction. But only five floors have been completed in 18 months.

| Apr 17, 2014

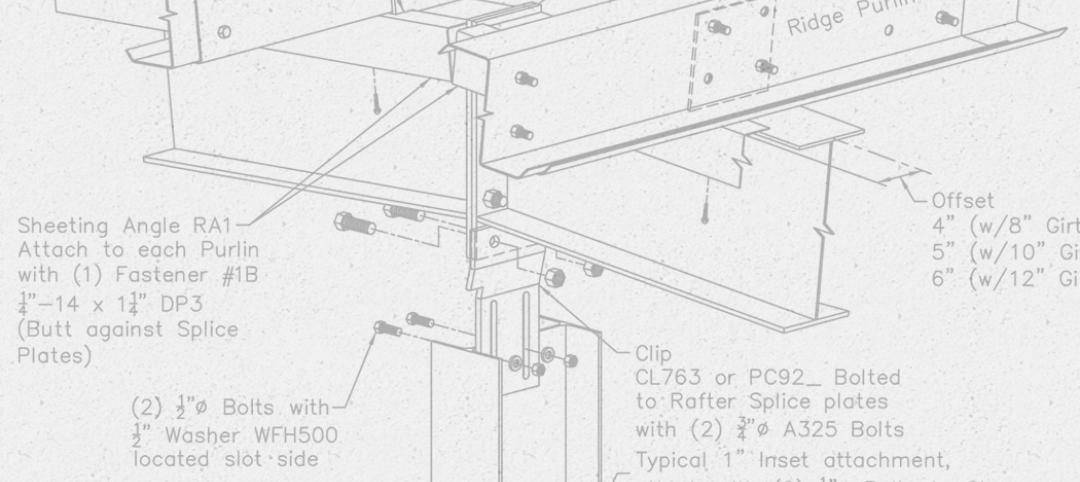

6 details that can throw off your schedule

In 1997, Apple told us to “Think Different.” So we did. We thought about what could happen if the world went mobile, if information was boundless, if we could carry our office in our back pocket. We’ve grown to love different and to expect change. And when it comes to Apple products, that’s not such a bad thing. When it comes to your building order, however, it’s not nearly as appealing.

| Apr 9, 2014

Steel decks: 11 tips for their proper use | BD+C

Building Teams have been using steel decks with proven success for 75 years. Building Design+Construction consulted with technical experts from the Steel Deck Institute and the deck manufacturing industry for their advice on how best to use steel decking.

| Apr 2, 2014

8 tips for avoiding thermal bridges in window applications

Aligning thermal breaks and applying air barriers are among the top design and installation tricks recommended by building enclosure experts.

| Mar 31, 2014

Tips for creating a competitive bid using codes and loads

Landing a project feels like winning a prize, sort of like finding that forgotten $20 bill in the pocket of a pair of jeans you haven’t worn in a while. But living on the “chance” of winning a job isn’t a great way to pay your electric bill. So, how do you swing the chances in your favor?

| Mar 26, 2014

A sales and service showcase

High Plains Equipment, a Case IH dealership in Devils Lake, N.D., constructs a larger facility to better serve its customers.

| Mar 26, 2014

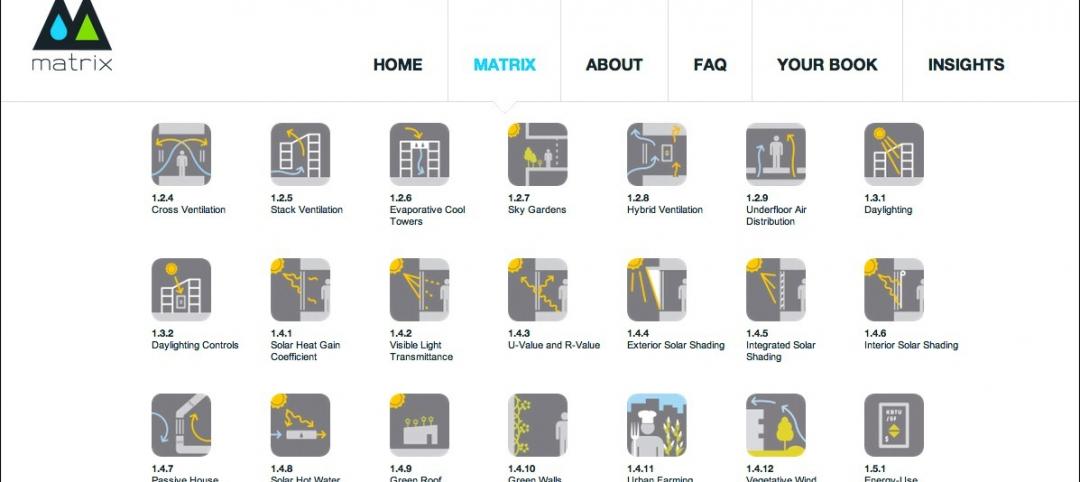

Callison launches sustainable design tool with 84 proven strategies

Hybrid ventilation, nighttime cooling, and fuel cell technology are among the dozens of sustainable design techniques profiled by Callison on its new website, Matrix.Callison.com.

| Mar 20, 2014

Common EIFS failures, and how to prevent them

Poor workmanship, impact damage, building movement, and incompatible or unsound substrate are among the major culprits of EIFS problems.

| Mar 19, 2014

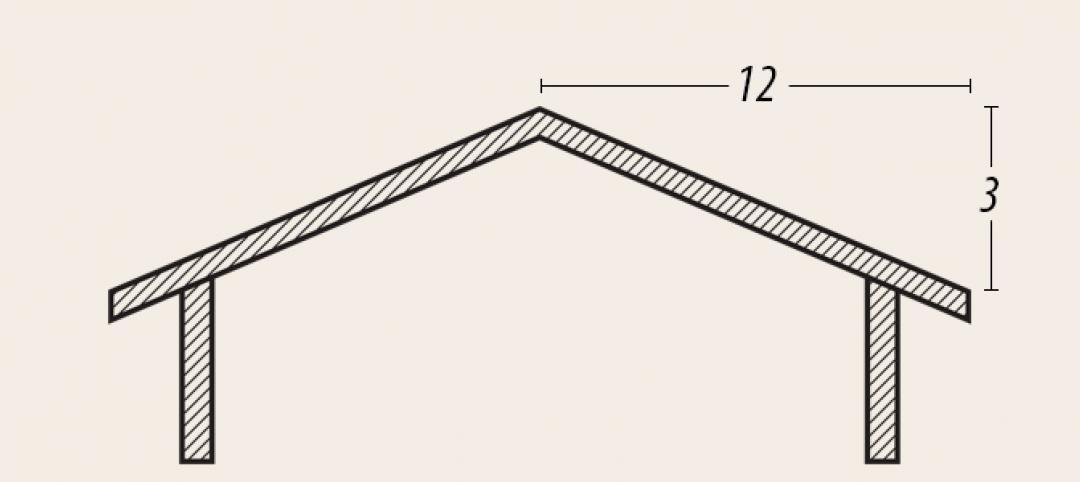

Frames: the biggest value engineering tip

In every aspect of a metal building, you can tweak the cost by adjusting the finish, panel thickness, and panel profile. These changes might make a few percentage points difference in the cost. Change the framing and you have the opportunity to affect 10-20 percent savings to the metal building portion of the project.