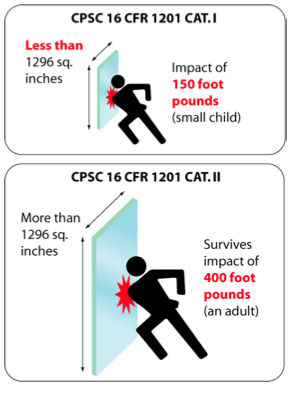

Wired glass was the only fire rated glass (FRG) product available for over 100 years. In traditional wired glass, the embedded wires hold annealed glass in place during the fire test to achieve a fire rating. While the wires give the illusion of increased strength and impact resistance, the opposite is true. Wired glass is not safety glazing. The wires actually weaken the glass, making it half as strong as ordinary window glass. Wired glass breaks easily on human impact, exposing razor sharp wires that can trap a victim’s limb in the opening and increase the severity of the injury. Alarmingly, wired glass is the most commonly used FRG product found in educational facilities, leading to over 2,500 wired glass impact injuries in schools every year. In 1977, the Consumer Product Safety Commission (CPSC) enacted a federal safety glazing standard (16 CFR 1201) to protect people from injury due to accidental impact with glazing. The building codes apply the CPSC standard to require that glazing used in hazardous locations, such as doors and sidelites, must meet minimum Category I and II impact standards, depending on the size of the glazing panel. Smaller glazing panels in sizes up to 1296 square inches must meet the Category I impact test of 150 ft. lbs. Larger glazing panels must meet the higher Category II standard impact test of 400 ft. lbs. of impact resistance. At the time the federal standard was enacted, wired glass manufacturers alleged they lacked the technology make a fire rated product that could meet the new CPSC standards. Since wired glass was the only FRG product available in 1977, the IBC granted wired glass a temporary exemption from meeting the CPSC standard. This exemption allowed wired glass used in fire assemblies to meet a lower ANSI Z97.1 impact standard of 100 ft. lbs., which the CPSC acknowledged was inadequate to protect anyone except children under five. For more information, click on the link below.

Related Stories

| Aug 11, 2010

NoricF4 custom metal ICF frames receive fire ratings, comply with antiterrorism standards for buildings

Reward Wall Systems' NoricF4 Custom Metal ICF Frames have received fire ratings of 1.5 hours to 3 hours and they have been evaluated to be in compliance with the prescriptive requirements of the Department of Defense Minimum Antiterrorism Standards for Buildings for blast/force protection.

| Aug 11, 2010

AIA Course: Enclosure strategies for better buildings

Sustainability and energy efficiency depend not only on the overall design but also on the building's enclosure system. Whether it's via better air-infiltration control, thermal insulation, and moisture control, or more advanced strategies such as active façades with automated shading and venting or novel enclosure types such as double walls, Building Teams are delivering more efficient, better performing, and healthier building enclosures.

| Aug 11, 2010

Glass Wall Systems Open Up Closed Spaces

Sectioning off large open spaces without making everything feel closed off was the challenge faced by two very different projects—one an upscale food market in Napa Valley, the other a corporate office in Southern California. Movable glass wall systems proved to be the solution in both projects.