The problems resulting from building deflection have likely troubled builders since the very first multistory building. Deflection is the bending of joists, trusses or rafters associated with overloaded structures. Typically, deflection causes unsightly cracks in the drywall along the inside corners where the wall meets the ceiling. Over time, deflection can worsen causing visual concerns, additional maintenance costs and structural problems.

Typical damage caused by building deflection. Without Deflection Bead, building deflection is absorbed by the walls, causing cracking and blisters.

Typical damage caused by building deflection. Without Deflection Bead, building deflection is absorbed by the walls, causing cracking and blisters.

In Chicago, Denk & Roche Builders noticed that some previously constructed multistory buildings had inside corner cracking due to deflection. When commissioned to complete two 11-story retirement community buildings, Denk & Roche Builders wished to combat unsightly cosmetic damage and structural concerns caused by deflection. To prevent deflection damage, Denk & Roche Builders turned to Trim-Tex Wall Mounted Deflection Bead.

Trim-Tex Wall Mounted Deflection Bead features a coextruded flexible gasket that compresses under deflection pressure, preventing drywall cracks and blisters. To effectively combat deflection troubles, Deflection Bead is installed at the head of wall detail where it can withstand up to 7/16” of deflection movement. If the floor system springs back up the gasket expands back up, keeping it tight against the ceiling. Trim-Tex Deflection Bead protects the inside corner from cracks and pressure due to building deflection without compromising the design of the building. Deflection Bead also saves the building owner money by lowering building maintenance costs and reducing the likelihood of future deflection-related repairs.

For more information, visit www.trim-tex.com.

Related Stories

| Dec 28, 2014

Robots, drones, and printed buildings: The promise of automated construction

Building Teams across the globe are employing advanced robotics to simplify what is inherently a complex, messy process—construction.

Sponsored | | Dec 5, 2014

Best practices for force transfer around openings

As wood-frame construction is continuously evolving, designers in many parts of the U.S. are optimizing design solutions that require the understanding of force transfer between elements in the lateral load-resisting system.

Sponsored | | Nov 19, 2014

Robust structural frame supports historic building renovation in Newport, R.I.

The Audrain Building on Newport’s celebrated Bellevue Avenue was designed by New York architect Bruce Price in the early 1900s with intricate exterior detailing that exudes an enduring sense of luxury and tradition.

| Nov 6, 2014

Demountable structural steel could up the ante on sustainability

Demountable structural steel assemblies would be a greener way to make use of steel in the construction industry than recycling.

Sponsored | | Nov 5, 2014

How to maximize affordability and sustainability through all-wood podiums

Wood podium construction takes an age-old material and moves it into the 21st century.

| Nov 3, 2014

AISC seeks entries for 2015 IDEAS2 Awards

These prestigious awards recognize outstanding achievement in engineering and architecture on structural steel projects across the country.

Sponsored | | Oct 13, 2014

CLT, glulam deliver strength, low profile, and aesthetics for B.C. office building

When he set out to design his company’s new headquarters building on Lakeshore Road in scenic Kelowna, B.C., Tim McLennan of Faction Projects knew quickly that cross-laminated timber was an ideal material.

| Oct 13, 2014

Department of Agriculture launches Tall Wood Building Competition

The competition invites U.S. developers, institutions, organizations, and design teams willing to undertake an alternative solution approach to designing and building taller wood structures to submit entries for a prize of $2 million.

Sponsored | | Oct 7, 2014

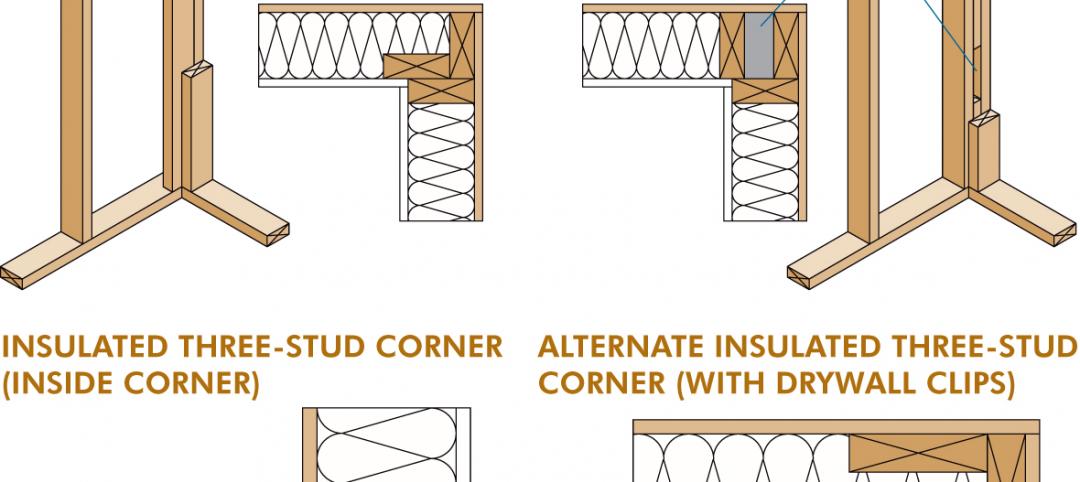

Boost efficiency with advanced framing

As architects continue to search for ways to improve building efficiencies, more and more are turning to advanced framing methods, particularly for multifamily and light commercial projects.

| Jul 24, 2014

MIT researchers explore how to make wood composite-like blocks of bamboo

The concept behind the research is to slice the stalk of bamboo grass into smaller pieces to bond together and form sturdy blocks, much like conventional wood composites.