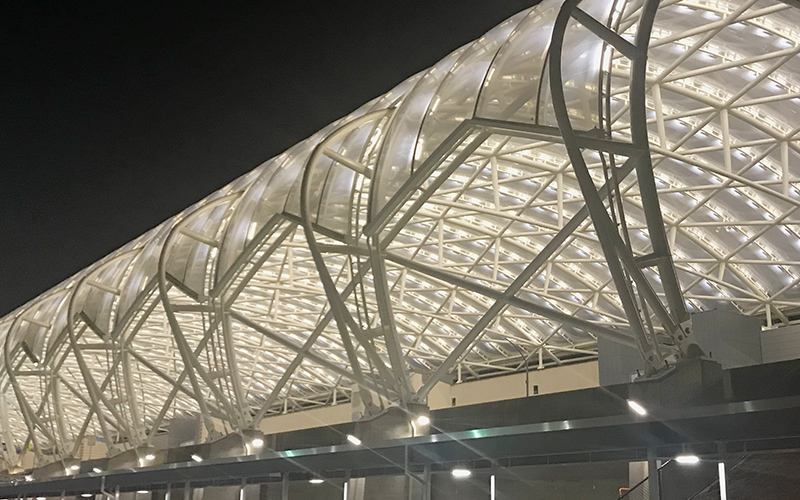

Hartsfield-Jackson Atlanta International, the world’s busiest airport, is in the midst of a $6 billion, 20-year expansion and modernization program. A major part of that program is an overhaul of the Central Passenger Terminal Complex (CPTC), which serves as the airport’s entrance and exit for all domestic traffic. As part of the CPTC updates, Atlanta commissioned architecture firm HOK to design a massive pair of canopies to stretch over curbside pickup and dropoff areas, protecting passengers from the elements and giving the airport a pair of iconic architectural pieces.

The Challenge

Building anything at the busiest airport in the world is bound to involve logistical challenges, but planners had a truly ambitious goal in mind for this project: Build two soaring canopies — 864 feet long, 72 feet tall and 194 feet wide, arching over eight lanes of traffic each — without disrupting airport operations or the 275,000 passengers who pass through daily. To accomplish this feat, designers had to figure out how to construct and install intricate steel diagrid lattices without closing traffic lanes or blocking airport entrances with construction work. Further, the new structures would have to be largely supported by existing construction, as installing extensive new supports or pilings would cause too much disruption to airport operations. That meant no new columns at the terminal curb and a limited ability to reinforce existing supports.

Modeling Minimizes Disruption

The first step was figuring out exactly how to design the lattice so it could be erected with as little disruption as possible. HOK’s designers used HOK STREAM, a proprietary parametric modeling and optimization tool, to plan the lattice’s structure, making the most of existing supports while minimizing the amount of retrofit work required. Additionally, analytic desktop models, wind tunnel testing and computational fluid dynamics were used to aid design, finding optimal structural load paths and planning for the large temperature variations between Atlanta’s hot summers and cool winters. Using these tools, designers were able to come up with a plan that would minimize required construction time and put two-thirds of the new load onto support piers that could be installed with minimal disruption, with the rest of the load carried by pre-existing columns.

Logistical Heavy Lifting

While every construction project has logistical components, the unique challenges facing the canopy designers meant logistics had to be top of mind from beginning to end. Major work was only possible during limited traffic shutdowns between 10:00 p.m. and 4:00 a.m. every day, so the steel had to be carefully fabricated to be rapidly erected in the available time. To make the best use of the time they had, the team created a 4D schedule that mapped out precisely when and where each piece had to be installed, detailed in a comprehensive 500-page plan. And to make sure that plan went off without a hitch, fabricators started working a full year before construction began, custom-making the components of the lattice’s 38 identical trusses out of more than 3,500 tons of domestic steel.

HSS Solve for Efficiency and Easy Erection

HSS from Atlas Tube helped designers find solutions to their logistical and structural challenges. Using 14", 18" and 20" HSS pipe for the trusses, fabricators were able to bend each section to precise tolerances and cut miters to exact specifications in order to minimize the time and material needed for on-site welding. The high strength-to-weight ratio of HSS helped as well, making it possible to design canopies strong enough to withstand structural and environmental forces with minimal new support.

An Award-winning Effort

Ultimately, all the planning paid off, and the second canopy was completed a month ahead of schedule in October 2019. By using high-efficiency HSS and advanced computer modeling, the team was able to create a pair of iconic landmarks for Atlanta’s gateway to the world without impeding the airport’s efficiency. And the world has taken notice, with the canopies winning several awards, including the American Institute of Steel Construction’s 2020 IDEAS² Award for Sculptures / Art Installations / Non-building Structures and an NCSEA Excellence in Structural Engineering Award in 2019.

Related Stories

| Apr 23, 2012

Thornton Tomasetti project wins AISC Merit Award

Thornton Tomasetti provided structural design services through construction administration to architect HOK for the 1.6-million-sf tower and tiara structure, which comprises 15 steel tube arches spanning approximately 158 feet horizontally and 130 feet vertically from the top of the main building roof.

| Apr 17, 2012

FMI report examines federal construction trends

Given the rapid transformations occurring in the federal construction sector, FMI examines the key forces accelerating these changes, as well as their effect on the industry.

| Mar 26, 2012

McCarthy tops off Math and Science Building at San Diego Mesa College

Designed by Architects | Delawie Wilkes Rodrigues Barker, the new San Diego Mesa College Math and Science Building will provide new educational space for students pursuing degree and certificate programs in biology, chemistry, physical sciences and mathematics.

| Mar 14, 2012

Hearing to decide fate of unfinished Harmon in Las Vegas under way

The testimony began with CityCenter consulting engineer Chukwuma Ekwueme methodically showing photo after photo of parts of the Harmon, where he and his team had chipped away the concrete pillars and beams to examine the steel reinforcing bars inside.

| Mar 6, 2012

Gensler and Skender complete new corporate headquarters for JMC Steel in Chicago

Construction was completed by Skender in just 12 weeks.

| Feb 20, 2012

All Steel names Breagy director of metro New York

Breagy is responsible for overseeing this region’s sales team while strategically coordinating the sales efforts of Allsteel dealers and representatives in the tri-state area.

| Feb 10, 2012

LAX Central Utility Plant project tops out

Construction workers placed the final structural steel beam atop the Plant, which was designed with strict seismic criteria to help protect the facility and airport utilities during an earthquake.

| Jan 9, 2012

METALCON International 2012 announced

METALCON 2012 is scheduled for Oct. 9-11 at the Donald E Stephens Convention Center, Hall A, Rosemont, Ill.

| Dec 20, 2011

BCA’s Best Practices in New Construction available online

This publicly available document is applicable to most building types and distills the long list of guidelines, and longer list of tasks, into easy-to-navigate activities that represent the ideal commissioning process.

| Dec 2, 2011

What are you waiting for? BD+C's 2012 40 Under 40 nominations are due Friday, Jan. 20

Nominate a colleague, peer, or even yourself. Applications available here.