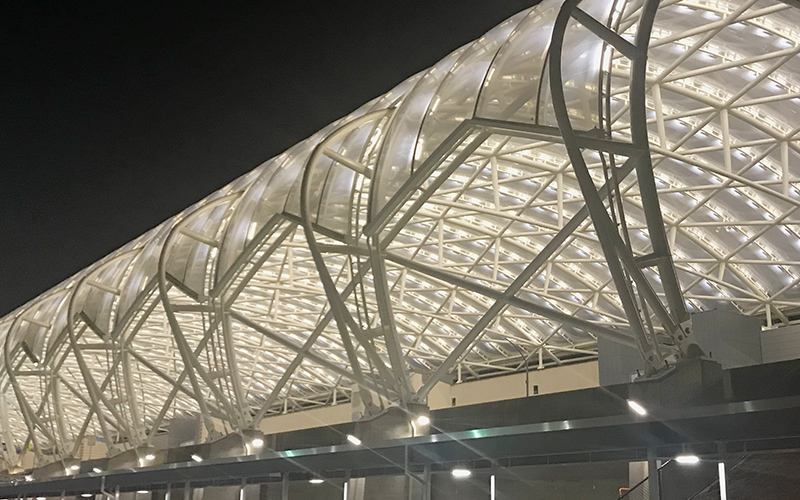

Hartsfield-Jackson Atlanta International, the world’s busiest airport, is in the midst of a $6 billion, 20-year expansion and modernization program. A major part of that program is an overhaul of the Central Passenger Terminal Complex (CPTC), which serves as the airport’s entrance and exit for all domestic traffic. As part of the CPTC updates, Atlanta commissioned architecture firm HOK to design a massive pair of canopies to stretch over curbside pickup and dropoff areas, protecting passengers from the elements and giving the airport a pair of iconic architectural pieces.

The Challenge

Building anything at the busiest airport in the world is bound to involve logistical challenges, but planners had a truly ambitious goal in mind for this project: Build two soaring canopies — 864 feet long, 72 feet tall and 194 feet wide, arching over eight lanes of traffic each — without disrupting airport operations or the 275,000 passengers who pass through daily. To accomplish this feat, designers had to figure out how to construct and install intricate steel diagrid lattices without closing traffic lanes or blocking airport entrances with construction work. Further, the new structures would have to be largely supported by existing construction, as installing extensive new supports or pilings would cause too much disruption to airport operations. That meant no new columns at the terminal curb and a limited ability to reinforce existing supports.

Modeling Minimizes Disruption

The first step was figuring out exactly how to design the lattice so it could be erected with as little disruption as possible. HOK’s designers used HOK STREAM, a proprietary parametric modeling and optimization tool, to plan the lattice’s structure, making the most of existing supports while minimizing the amount of retrofit work required. Additionally, analytic desktop models, wind tunnel testing and computational fluid dynamics were used to aid design, finding optimal structural load paths and planning for the large temperature variations between Atlanta’s hot summers and cool winters. Using these tools, designers were able to come up with a plan that would minimize required construction time and put two-thirds of the new load onto support piers that could be installed with minimal disruption, with the rest of the load carried by pre-existing columns.

Logistical Heavy Lifting

While every construction project has logistical components, the unique challenges facing the canopy designers meant logistics had to be top of mind from beginning to end. Major work was only possible during limited traffic shutdowns between 10:00 p.m. and 4:00 a.m. every day, so the steel had to be carefully fabricated to be rapidly erected in the available time. To make the best use of the time they had, the team created a 4D schedule that mapped out precisely when and where each piece had to be installed, detailed in a comprehensive 500-page plan. And to make sure that plan went off without a hitch, fabricators started working a full year before construction began, custom-making the components of the lattice’s 38 identical trusses out of more than 3,500 tons of domestic steel.

HSS Solve for Efficiency and Easy Erection

HSS from Atlas Tube helped designers find solutions to their logistical and structural challenges. Using 14", 18" and 20" HSS pipe for the trusses, fabricators were able to bend each section to precise tolerances and cut miters to exact specifications in order to minimize the time and material needed for on-site welding. The high strength-to-weight ratio of HSS helped as well, making it possible to design canopies strong enough to withstand structural and environmental forces with minimal new support.

An Award-winning Effort

Ultimately, all the planning paid off, and the second canopy was completed a month ahead of schedule in October 2019. By using high-efficiency HSS and advanced computer modeling, the team was able to create a pair of iconic landmarks for Atlanta’s gateway to the world without impeding the airport’s efficiency. And the world has taken notice, with the canopies winning several awards, including the American Institute of Steel Construction’s 2020 IDEAS² Award for Sculptures / Art Installations / Non-building Structures and an NCSEA Excellence in Structural Engineering Award in 2019.

Related Stories

| May 10, 2011

AISC honors top steel industry professionals

Roberto Leon, William Segui, Atorod Azizinamini, David Platten, Reidar Bjorhovde, Karl Frank, David I. Ruby, and Jon Magnusson are honored by the American Institute of Steel Construction (AISC) for their great contributions to the advancement of the structural steel design and construction industry. The award recipients will be recognized on May 11 at the 2011 NASCC: The Steel Conference in Pittsburgh.

| May 3, 2011

Demand for steel grows, led by developing economies

According to the World Steel Association's short range outlook for 2011 and 2012, steel use will increase by 5.9% in 2011, and an additional 6% in 2012. This forecast suggests that by 2012, steel use in the developed world will still be 14% below 2007 levels, whereas in the emerging and developing economies, it will be 38% above. In 2012, emerging and developing economies will account for 72% of world steel demand in contrast to 61% in 2007.

| Apr 5, 2011

SSPC, AISC announce joint standard for paint shop certification

SSPC: The Society for Protective Coatings and the American Institute of Steel Construction (AISC) are pleased to announce a joint certification standard for shop application of protective coatings. The standard, "Certification Standard for Shop Application of Complex Protective Coating Systems," describes requirements for certification of firms that shop apply complex painting systems.

| Mar 10, 2011

Steel Joists Clean Up a Car Wash’s Carbon Footprint

Open-web bowstring trusses and steel joists give a Utah car wash architectural interest, reduce its construction costs, and help green a building type with a reputation for being wasteful.

| Nov 16, 2010

CityCenter’s new Harmon Hotel targeted for demolition

MGM Resorts officials want to demolish the unopened 27-story Harmon Hotel—one of the main components of its brand new $8.5 billion CityCenter development in Las Vegas. In 2008, inspectors found structural work on the Harmon didn’t match building plans submitted to the county, with construction issues focused on improperly placed steel reinforcing bar. In January 2009, MGM scrapped the building’s 200 condo units on the upper floors and stopped the tower at 27 stories, focusing on the Harmon having just 400 hotel rooms. With the Lord Norman Foster-designed building mired in litigation, construction has since been halted on the interior, and the blue-glass tower is essentially a 27-story empty shell.

| Nov 5, 2010

New Millennium’s Gary Heasley on BIM, LEED, and the nonresidential market

Gary Heasley, president of New Millennium Building Systems, Fort Wayne, Ind., and EVP of its parent company, Steel Dynamics, Inc., tells BD+C’s Robert Cassidy about the Steel Joist Manufacturer’s westward expansion, its push to create BIM tools for its products, LEED, and the outlook for the nonresidential construction market.

| Nov 3, 2010

Dining center cooks up LEED Platinum rating

Students at Bowling Green State University in Ohio will be eating in a new LEED Platinum multiuse dining center next fall. The 30,000-sf McDonald Dining Center will have a 700-seat main dining room, a quick-service restaurant, retail space, and multiple areas for students to gather inside and out, including a fire pit and several patios—one of them on the rooftop.

| Oct 13, 2010

Prefab Trailblazer

The $137 million, 12-story, 500,000-sf Miami Valley Hospital cardiac center, Dayton, Ohio, is the first major hospital project in the U.S. to have made extensive use of prefabricated components in its design and construction.

| Oct 12, 2010

University of Toledo, Memorial Field House

27th Annual Reconstruction Awards—Silver Award. Memorial Field House, once the lovely Collegiate Gothic (ca. 1933) centerpiece (along with neighboring University Hall) of the University of Toledo campus, took its share of abuse after a new athletic arena made it redundant, in 1976. The ultimate insult occurred when the ROTC used it as a paintball venue.

| Oct 11, 2010

MBMA Releases Fire Resistance Design Guide for metal building systems

The Metal Building Manufacturers Association (MBMA) announces the release of the 2010 Fire Resistance Design Guide for Metal Building Systems. The guide provides building owners, architects, engineers, specifiers, fire marshals, building code officials, contractors, product vendors, builders and metal building manufacturers information on how to effectively meet fire resistance requirements of a project with metal building systems.