One of the largest public hospitals in the nation, and the largest ever to be built in one phase, the new Parkland Hospital in Dallas, Texas opened to patients in August 2015. This AIA award-winning, LEED Gold certified building doubles the size of the old, overcrowded Parkland. It incorporates the most advanced design features to serve the clinical and human needs of practitioners, patients and visitors. And it features a remarkable design adorned by more than more than 4.5 acres of ALPOLIC® materials.

The project was designed by Corgan, one of the country’s top 10 architectural firms, in collaboration with HDR, one of the leading healthcare designers. Construction was done through a fast-track collaboration between HDR+Corgan and BARA, a joint venture of Balfour Beatty Construction, Austin Commercial, H.J. Russell and Azteca Enterprises.

The new Parkland provides a 2.8 million-square-foot campus that houses state-of-the-art clinical facilities plus 862 single-patient rooms with private bathrooms and plenty of space for visitors. Among many features that contribute to a calm, healing stay are the abundant natural lighting, verdant wellness gardens and a unique hallway and elevator layout that keeps noisy clinical and housekeeping activities “off stage,” leaving patient areas calm and uncongested.

The exterior resembles two skyscrapers tipped over on their side and intersecting each other in an “L” formation. The 17-story acute care tower cantilevers over a second 10-story tower that houses the WISH: the women, infant and specialty hospital. At the intersection is a 180-foot open span that allows for natural daylight to reach the NICU rooms below. It also opens up the flat surfaces of the building to provide an intriguing sense of dimensionality.

The design features extensive glazing complemented by almost 200,000 square feet of ALPOLIC®/fr aluminum composite material in a custom three-coat Kynar® finish of PEX Pewter Metallic. The ALPOLIC® material was fabricated by NOW Specialties using their NOW 3100 route-and-return dry system, a gasketed design that requires virtually no maintenance.

Despite the sheer size of the project, Edgar Sanchez of NOW Specialties recalls, “There were no problems with delivery, and the color match was phenomenal. We didn’t have any variations between batch one, two and three. We know in the industry, with a metallic color, you need to isolate that depending on the number of shipments, but this was perfect.”

That level of consistency, performance and delivery is no surprise to Nate DeVore, project architect for Corgan. “ALPOLIC® materials is in our master spec for a reason,” he says. “We trust them and we have a history with them. There are other products out there, but we’ve used ALPOLIC® materials in the past on several large products, and we know they can deliver. It’s always a great look, a great outcome.”

ALPOLIC® materials in a shimmering metallic finish

ALPOLIC® materials in a shimmering metallic finish

Related Stories

Sponsored | Cladding and Facade Systems | Mar 24, 2015

Designers turn a struggling mall into a hub of learning and recreation

Architects help Nashville government transform a struggling mall into a new community space.

Brick and Masonry | Feb 5, 2015

3D-printed 'cool brick' may provide cooling solution for arid locations

Cool Brick is made of porous ceramic bricks set in mortar. The bricks absorb water, which cools the air as it passes through the unit.

| Dec 28, 2014

Robots, drones, and printed buildings: The promise of automated construction

Building Teams across the globe are employing advanced robotics to simplify what is inherently a complex, messy process—construction.

Sponsored | | Sep 25, 2014

Architects transform warehouse into office space while preserving its historic nature

When it came time for CSHQA, an award-winning, full-service architecture and engineering firm, to move office locations, they didn’t need to look far. The 20,000-square-foot warehouse was not only a mere three blocks away, its renovation would be an ideal demonstration piece to show existing and potential clients.

| Sep 7, 2014

Building the cladding palette: panels, rainscreens, and veneers [AIA course]

When it comes to cost, performance, and aesthetics—not to mention maintenance and long-term resilience—the evaluation of cladding materials and façade systems is more complex than ever. This course is worth 1.0 AIA CES HSW learning units.

| Jul 1, 2014

Sochi's 'kinetic façade' may steal the show at the Winter Olympics

The temporary pavilion for Russian telecom operator MegaFon will be wrapped with a massive digital "pin screen" that will morph into the shape of any face.

| May 27, 2014

Fire Rated Glass contributes to open lab environment at JSNN

Openness and transparency were high priorities in the design of the Joint School of Nanoscience & Nanoengineering within the Gateway University Research Park in Greensboro, N.C. Because the facility’s nanobioelectronics clean room houses potentially explosive materials, it needed to be able to contain flames, heat, and smoke in the event of a fire. SPONSORED CONTENT

| Mar 26, 2014

Zaha Hadid's glimmering 'cultural hub of Seoul' opens with fashion, flair [slideshow]

The new space, the Dongdaemun Design Plaza, is a blend of park and cultural spaces meant for the public to enjoy.

| Mar 20, 2014

Common EIFS failures, and how to prevent them

Poor workmanship, impact damage, building movement, and incompatible or unsound substrate are among the major culprits of EIFS problems.

| Mar 7, 2014

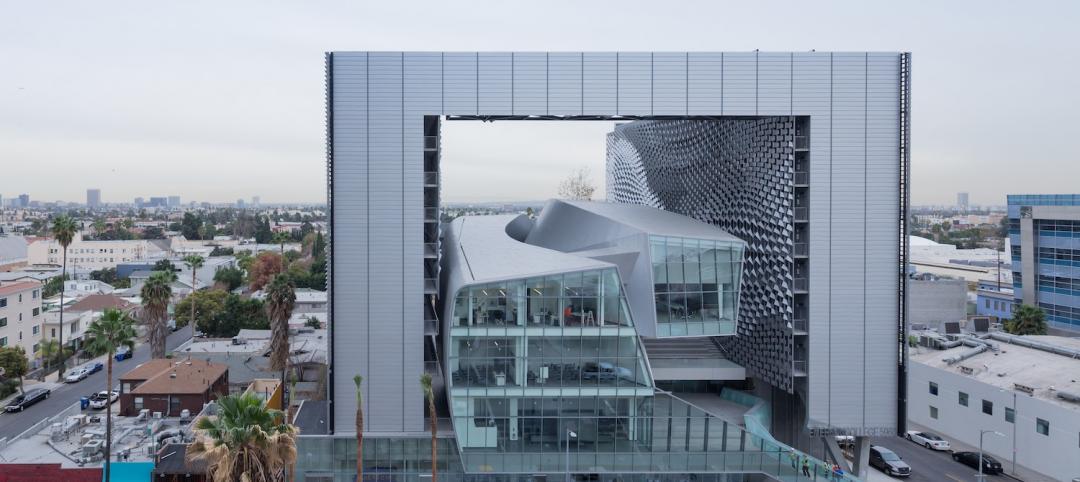

Thom Mayne's high-tech Emerson College LA campus opens in Hollywood [slideshow]

The $85 million, 10-story vertical campus takes the shape of a massive, shimmering aircraft hangar, housing a sculptural, glass-and-aluminum base building.