Editor's note: This article was originally published as part of an AIA/CES Discovery course: "EIFS: How to succeed with exterior insulation and finish systems." Take this free course at BDCUniversity.com.

Originally, EIFS was designed as a “perfect barrier” system; that is, one which provides waterproofing protection at the exterior face of the cladding. The idea of barrier cladding assemblies is to create a face-sealed façade that repels moisture to keep the building dry.

Unfortunately, barrier systems are rarely perfect. All it takes to compromise water tightness is a small breach in the exterior finish, such as a crack due to expansion, sealant failure at joints, or impact damage. Once water finds its way into a barrier system, it usually can’t find its way back out. Water trapped in the wall can lead to leaks, wet substrate, mold, deterioration of building components, and, eventually, collapse of the weakened cladding.

Any number of deficiencies can lead to EIFS failure. The major culprits are poor workmanship, damp climate, impact damage, building movement, and incompatible or unsound substrate.

How to avoid poor workmanship

There are numerous opportunities for installation errors and poor workmanship to ruin an EIFS job.

Sealant joints are a major source of problems with EIFS cladding. Incorrect selection or application of sealants, or missing sealants, provides an easy path for water entry and premature deterioration. Inappropriate sealant may even lead to cohesive failure of the EIFS finish coat. Sealant erroneously applied to the finish coat, rather than to the mesh-reinforced base coat, is a common source of problems.

Invasive probes, including test cuts of existing EIFS cladding, can uncover hidden deterioration conditions. A seemingly impervious exterior may mask wet or crumbling wall board beneath the surface. Image courtesy Hoffmann Architects

Flashings that are incorrectly installed or missing provide a conduit for water infiltration. Door and window openings should incorporate flashings to direct water away from headers and sills. At roof/wall intersections, drip-edge flashings should be installed to channel rainwater away from the wall face.

Base coat thicknesses that don’t meet the manufacturer’s guidelines are another source of trouble for EIFS façades. A base coat that is too thin provides insufficient waterproofing protection, whereas a base coat that is too thick may lead to cracking.

Reinforcing mesh that reads through at joint edges or terminations can indicate inadequate coating thickness. Alternatively, the mesh may have been insufficiently embedded in the base coat. Continuing the mesh-reinforced base coat around to the back of the insulation board, known as “backwrapping,” is critical to providing continuous waterproofing protection at edges, penetrations, and terminations. Where appropriate, factory-formed track may be used at foundation terminations instead of backwrapping.

Aesthetic joints (V-grooves) that align with insulation board joints can lead to cracks as the building moves. Mesh-reinforced base coat should be continuous at recessed features.

At the corners of windows, doors, and louvers, EIFS design should incorporate butterfly reinforcement, with diagonal pieces of mesh that provide additional reinforcing and prevent cracking. Image courtesy Hoffmann Architects

Window and door corners, like aesthetic joints, should not align with insulation board joints. “Butterfly” reinforcement, whereby rectangular pieces of reinforcing mesh are laid diagonally at the corners of windows, doorways, and other openings, is important to preventing cracking.

Expansion joints are too often neglected in EIFS construction, but they are no less critical here than with other types of cladding. Expansion joints should be used:

• At changes in building height

• At areas of anticipated movement

• At floor lines (particularly for wood frame construction)

• Where the substrate changes

• Where prefabricated panels abut one another

• At intersections with dissimilar materials

• Where expansion joints exist in the substrate or supporting construction

Insulation board should not bridge expansion joints in masonry or concrete substrates. Instead, an expansion joint should be created in the EIFS insulation over the underlying joint. Insulation board should meet the manufacturer’s recommended minimum thickness (usually 3/4 inch), even at aesthetic joints and recesses. Vertical joints in the insulation should be staggered in a running bond pattern in successive courses, with boards abutted tightly to one another.

Gaps between boards should never be filled with base coat or adhesive, which can cause cracking; rather, slivers of insulation may be wedged between boards where needed. Selecting a board adhesive that is compatible with both the insulation and the substrate is critical to successful performance of EIFS.

This infrared thermographic scan reveals trapped moisture at insulation board joints. Image courtesy Hoffmann Architects

Deal with climate factors

A humid climate with limited drying potential can devastate some EIFS assemblies, particularly when the rate of wetting exceeds the rate of drying. Poor design and installation exacerbate this problem by providing avenues for water to penetrate the cladding, while the humidity prevents damp walls from drying out.

The amount of rain deposited on a wall is dependent not only on climate, but also on the architecture and siting of the structure. Building height, overhangs, exposure, and façade details all affect the path of rainfall, channeling more or less moisture toward the cladding.

Cold climates may also lead to premature failure, particularly when EIFS coatings are applied at temperatures below the manufacturer’s design range.

Guard EIFS against impact

EIFS assemblies consist of a thin, brittle coating over a soft substrate and are easily damaged by impact. Holes, dents, or scrapes can lead to water infiltration, so it’s prudent to provide extra reinforcement at susceptible locations.

Areas needing impact protection should use heavy-duty mesh, usually 12 to 20 ounces, rather than standard 4.5-ounce mesh. For outside corners, the design professional may specify a heavier corner mesh to guard against excess wear and damage. Intricate decorative elements require a lightweight, flexible detail mesh, which conforms to fine contours and ornamental details while still providing some measure of impact protection.

Impact damage that is not repaired promptly provides a pathway for leaks. Image courtesy Hoffmann Architects

Account for building movement

Wood substrates tend to exhibit cross-grain shrinking, along with expansion and contraction from changes in humidity. For concrete, movement tends to come in the form of frame shortening, whereby concrete deforms over time due to shrinkage and creep. Steel structures are not immune to the effects of building movement, particularly at long-span beams, where transverse forces are greatest and deflection more likely. To prevent irregular cracking, sufficient provision for expansion and control joints should be part of your design.

Avoid use of incompatible or unsound substrate

Poor quality control in the production of oriented strand board (OSB), a common substrate for EIFS, has raised concerns about premature failure, so use a reputable manufacturer with a good track record. Gypsum board, often used with EIFS, tends to exhibit problems with moisture absorption, so avoid using it in damp or humid climates. Even if the substrate is of high quality and suitable for the building location, failure to correctly specify or install substrate attachment may lead to premature cladding problems.

Related Stories

| Jun 30, 2014

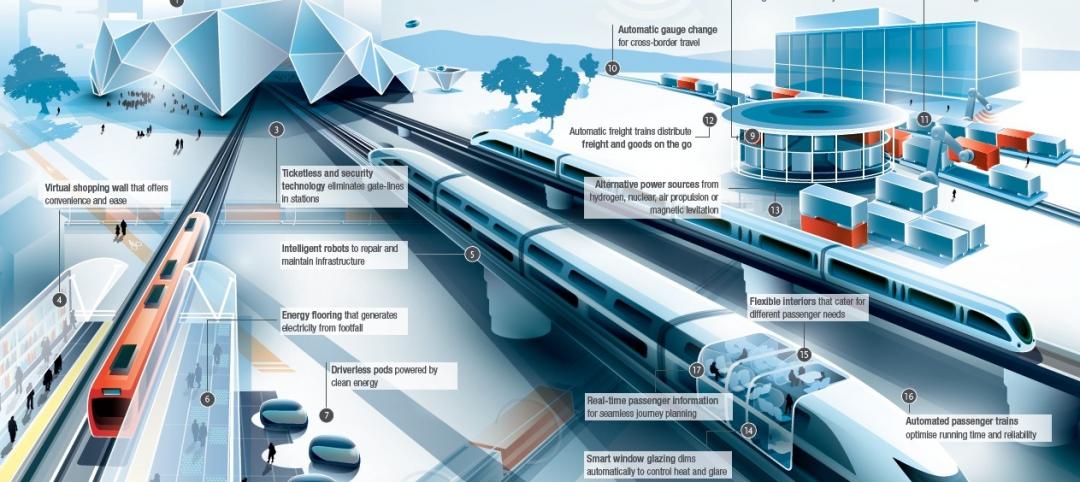

Arup's vision of the future of rail: driverless trains, maintenance drones, and automatic freight delivery

In its Future of Rail 2050 report, Arup reveals a vision of the future of rail travel in light of trends such as urban population growth, climate change, and emerging technologies.

| Jun 18, 2014

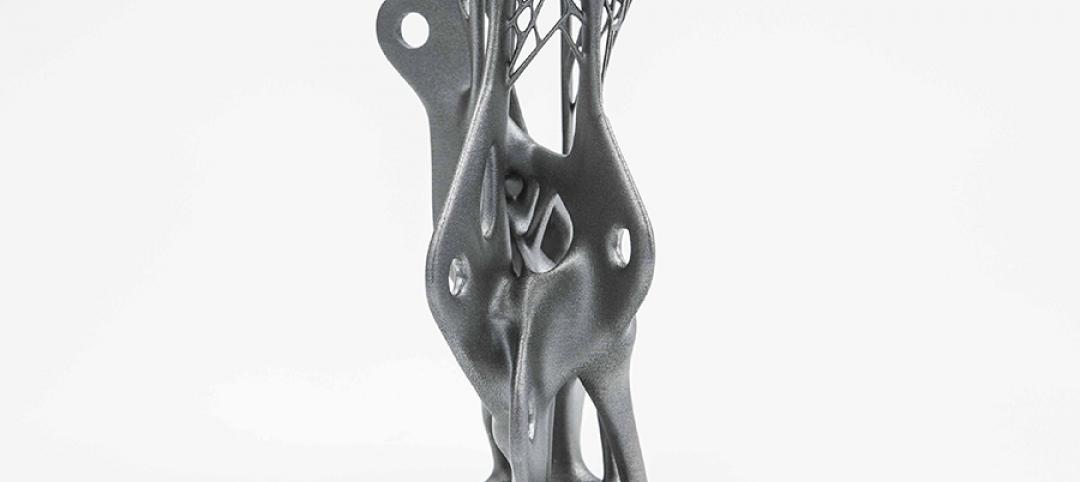

Arup uses 3D printing to fabricate one-of-a-kind structural steel components

The firm's research shows that 3D printing has the potential to reduce costs, cut waste, and slash the carbon footprint of the construction sector.

| Jun 12, 2014

Austrian university develops 'inflatable' concrete dome method

Constructing a concrete dome is a costly process, but this may change soon. A team from the Vienna University of Technology has developed a method that allows concrete domes to form with the use of air and steel cables instead of expensive, timber supporting structures.

| Jun 2, 2014

Parking structures group launches LEED-type program for parking garages

The Green Parking Council, an affiliate of the International Parking Institute, has launched the Green Garage Certification program, the parking industry equivalent of LEED certification.

| May 29, 2014

7 cost-effective ways to make U.S. infrastructure more resilient

Moving critical elements to higher ground and designing for longer lifespans are just some of the ways cities and governments can make infrastructure more resilient to natural disasters and climate change, writes Richard Cavallaro, President of Skanska USA Civil.

| May 23, 2014

Top interior design trends: Gensler, HOK, FXFOWLE, Mancini Duffy weigh in

Tech-friendly furniture, “live walls,” sit-stand desks, and circadian lighting are among the emerging trends identified by leading interior designers.

| May 20, 2014

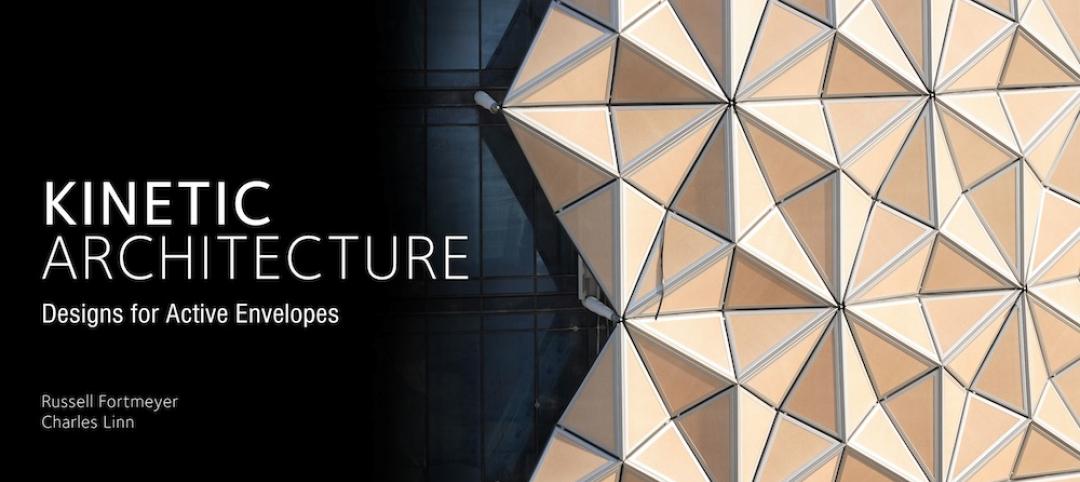

Kinetic Architecture: New book explores innovations in active façades

The book, co-authored by Arup's Russell Fortmeyer, illustrates the various ways architects, consultants, and engineers approach energy and comfort by manipulating air, water, and light through the layers of passive and active building envelope systems.

| May 19, 2014

What can architects learn from nature’s 3.8 billion years of experience?

In a new report, HOK and Biomimicry 3.8 partnered to study how lessons from the temperate broadleaf forest biome, which houses many of the world’s largest population centers, can inform the design of the built environment.

| May 13, 2014

19 industry groups team to promote resilient planning and building materials

The industry associations, with more than 700,000 members generating almost $1 trillion in GDP, have issued a joint statement on resilience, pushing design and building solutions for disaster mitigation.

| May 11, 2014

Final call for entries: 2014 Giants 300 survey

BD+C's 2014 Giants 300 survey forms are due Wednesday, May 21. Survey results will be published in our July 2014 issue. The annual Giants 300 Report ranks the top AEC firms in commercial construction, by revenue.