Right now, 33 states allow the sale of marijuana for medical purposes; another 14 allow it under more stringent medical supervision. Ten states have OK’d it for both medical and recreational use. Only Idaho, Nebraska, and South Dakota have a total ban on the sale of marijuana.

Cannabis is the source of THC (tetrahydrocannabinol)—the stuff that gets you high—and CBD (cannabidiol), which is used to treat anxiety, PTSD, sleep disorders, seizures, and pain. By law, CBD cannot contain more than 0.3% THC.

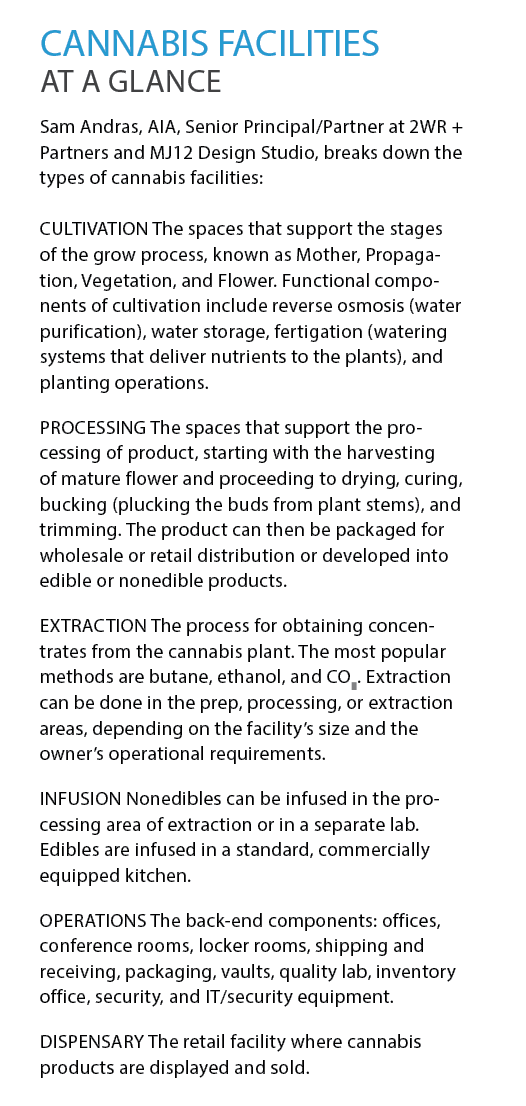

We talked to industry experts to learn what it takes to design and build cannabis facilities.

TAKING THE FIRST STEP

The first decision that must be made is whether to be on the “grow” side or the retail side of cannabis. (The accompanying chart describes the various types of cannabis facilities.) “The grow side is industrial, not flashy. It’s more about building science—the building envelope, HVAC, process flow, lighting, and insulation,” says Patrick Donaldson, LEED AP, CEM, CPHC, Principal Architect, Harka Architecture, Portland, Ore., who has designed half a dozen cultivation facilities.

Designers must consider such factors as the number of plants per square foot, the height of plants at harvest, the type of lighting, and the irrigation method, says Sam Andras, Senior Principal/Partner, MJ12 Design Studio, Columbus, Ga. You have to understand the flow of the functions and the required types of spaces as the cannabis plant moves through the production process. “Improper ratios of space, irrational flow, and flawed system design will adversely impact productivity,” says Andras, who has designed grow complexes as big as a million square feet.

Donaldson says his firm is working on its sixth dispensary. “There’s more of a design element to them” he says. “We ask clients, Are you going for a modern, clean, pharmacy look, or a laid-back, homey one?”

Satto Rugg, Owner/Principal in MerJ Architecture’s Santa Fe, N.M., office, says the trend is toward vertically integrated facilities that combine cultivation, extraction, post-processing, consumables manufacture, and quality assurance testing labs. “You have to understand every step of the process, from bringing seed into the facility up through a packaged product leaving the facility,” he says.

His firm is heading the work on two vertically integrated complexes, which can involve more than 20 subcontractors. “That’s the ideal role for the architect, to become the team leader in this process,” says Rugg.

Renovating an existing building and upgrading the envelope insulation will run $240/sf for a single-level cultivation facility with fixed benching, says Andras. The new thing, he says, is vertical indoor grows with multi-level “canopies”; these can cost $300–320/sf.

Dan Gustafik, President, Hybrid Tech LLC, West Linn, Ore., says maintaining temperature and airflow consistency is crucial in multi-level grows, to avoid shocking the plants.

Cultivation facilities can range in size from 3,000 sf to 1,000,000 sf or more and come in anywhere from $208/sf to $425/sf, says Gustafik. Processing and manufacturing facilities come in at $495–1,250/sf, depending on size and the amount of equipment, he says.

Construction costs for a dispensary run about the same as for an urgent-care center—about $200–250/sf, depending on how high-end the client wants go, says Sean Whalen, Senior Vice President, South Coast Improvement Co., Marion, Mass. He says a typical dispensary runs anywhere from 3,000 to 7,000 sf and can be built in 8–12 weeks.

Zoning regulations can be a huge obstacle, particularly for dispensaries. Design-build firm South Coast is completing a gut renovation on a $2 million dispensary for Commonwealth Alternative Care in Brockton, Mass., 25 miles south of Boston. The city requires such facilities to be 2,500 feet from schools, houses of worship, or areas of high use by children, says Whalen.

Parking can be a headache. “On Saturdays, there’s 300 cars outside these dispensaries,” says Whalen. Signage is heavily restricted by local jurisdictions. Translucent or opaque glazing is usually required. Boulder, Colo., now requires 100% wind-generated power for cannabis facilities, says MerJ Architecture’s Rugg.

Lighting is the single biggest operational cost in cannabis cultivation. Double-headed high-pressure sodium lamps are “still the go-to,” says Harka Architecture’s Donaldson, but LEDs are coming along. LECs—light-emitting ceramics, also known as ceramic metal halide (CMH) lamps—are also gaining interest from growers.

Correctly directing the lighting to avoid parts of the plants getting too much light and other parts not enough is crucial. Getting the “perfect spectrum” of lighting is also an art form, says Donaldson. “We’re finding that certain strains of marijuana like LEDs, some don’t.”

Heat buildup can be enormous. A single HPS lamp can produce 35,000 Btu/hour—heat that must be removed by the HVAC system.

Grow facilities have to be precisely controlled for humidity, lighting, airflow, and temperature to prevent mold or mildew growth or pest infestation that can ruin a whole crop or lead to a quality test failure. Environment control must be nearly up to clean room standards. “Creating a very stable environment with repeatable results provides the best product,” says Gustafik.

Contamination can demolish a whole crop. Employees must not drag spores, spider mites, pesticides, or bugs into the grow area from the outside or from locker rooms. Airflow between grow rooms must be contained.

Odor is “a big issue,” says Andras. Flowering cannabis plants give off a pungent smell. Charcoal filtration and bipolar ionization systems can mitigate the odor, but Gustafik says many operators neglect “scent control” in their initial planning, only to have it become their first stumbling block en route to permitting.

Fire protection is paramount in the extraction process, which uses extremely dangerous, high-pressure flammable gases like butane.

Denver has some of the strictest regulations in the country, says Nicole Delmage, AIA, Owner/Principal, MerJ Architecture, Denver. That leads to horrendous backlogs of permit applications awaiting approval by the fire marshal.

Security is tight for these facilities, says Andras. They must have controlled access to the site and to individual buildings, interior/exterior video, enhanced site lighting, and secure product storage.

Flexibility is also important. Harka Architecture is doing the interior design for a medical dispensary in Connecticut but is allowing space for retail use in the future. South Coast has set aside half the space in the medical dispensary it’s building outside Boston for the day when the client gets its recreational use license.

Everyone I talked to is eagerly anticipating federal decriminalization of cannabis in the next few years—and the bonanza it will bring in national and even international product distribution. The recently passed 2018 Farm Bill removes many of the federal restrictions against hemp, a fast-growing source of CBD. Nearly $600 million of hemp-derived CBD was sold in 2018, but that figure could reach $5 billion this year, according to the Brightfield Group.

Be warned. The cannabis business is risky. It’s estimated that 80% of projects fail in the first two years: half never get a license, the other half fail due to design and buildout problems, says Gustafik. Heightened competition is also driving down the final sales price of cannabis products in mature markets like Colorado—from $4,000/lb a few years ago, to $1,000/lb today.

Although a 2017 Quinnipiac poll found 94% support for medical use of marijuana nationwide, and other surveys have shown nearly 60% support for recreational use, cannabis is still a Schedule I drug under federal law. Until that onus is lifted, banks will be reluctant to lend to build cannabis facilities, and investors will have to come up with cash—and that can lead to underfunding and eventual failure.

If and when federal decriminalization of cannabis happens, it will attract players with almost limitless resources—notably pharmaceutical and tobacco giants—into the game.

Industry veterans like Sam Andras prefer to focus on how the availability of medical cannabis is changing people’s lives for the better. “When you talk to parents whose children have epilepsy,” he says, “the improvement in their lives thanks to medical cannabis is amazing.”

MODULAR CULTIVATION AND EXTRACTION UNITS SPEED UP TIME TO MARKET

Investors rushing into the exploding cannabis market want to get their operations up and running as fast as possible. But building new or reconstructing existing buildings can take 12–24 months. That’s too long a wait.

Four years ago, Denver-based entrepreneurs Dano Keys and Bruce Granger started FlexMOD, which builds and installs plug-and-play cannabis grow and extraction modules. The company now has five factories in the U.S. and one in Montreal.

The cultivation units measure 20 or 40 feet in length by 8 feet in width, can be fitted with lighting to the customer’s specification, and are built practically to cleanroom standards. “You have to grow under very strict, almost pharmaceutical-like conditions,” says Will Goodin, LEED AP, FlexMOD’s Director of Business Development. The company states it can deliver modules in 4–6 weeks.

Courtesy Flexmod.

Courtesy Flexmod.

FlexMOD extraction labs are built to meet NEC, OSHA, MED, and NFPA requirements. They come with one-hour fire-rated walls and are sparkproof and blastproof. The cost: $130,000. “Some investors balk at the price, but I know guys who tried to build it themselves, and it took eight months to get a permit and cost a quarter-million,” says Goodin.

FlexMOD supplies customers with an initial design and will refer them to a select set of architecture firms (MJ12 Design Studio being one) for help with the intricacies of workflow, automation, and space requirements for the various stages of the cannabis plant cycle. “That saves the client money in the long run,” says Goodin.

Related Stories

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

AEC Innovators | Jun 15, 2023

Rogers-O'Brien Construction pilots wearables to reduce heat-related injuries on jobsites

Rogers-O'Brien Construction (RO) has launched a pilot program utilizing SafeGuard, a safety-as-a-service platform for real-time health and safety risk assessment. Non-invasive wearables connected to SafeGuard continuously monitor personnel to prevent heat exhaustion on jobsites, reducing the risk of related injuries. RO is the first general contractor to pilot this program.

Office Buildings | May 15, 2023

Sixteen-story office tower will use 40% less energy than an average NYC office building

This month marks the completion of a new 16-story office tower that is being promoted as New York City’s most sustainable office structure. That boast is backed by an innovative HVAC system that features geothermal wells, dedicated outdoor air system (DOAS) units, radiant heating and cooling, and a sophisticated control system to ensure that the elements work optimally together.

K-12 Schools | May 12, 2023

In Virginia, a new high school building helps reimagine the experience for 1,600 students

In Virginia, the City of Alexandria recently celebrated the topping out of a new building for Alexandria City High School. When complete in 2025, the high-performance structure will accommodate 1,600 students.

Hotel Facilities | May 9, 2023

A new camping destination near Utah’s Zion National Park offers a variety of all-season lodgings and amenities

Outdoor lodging brand AutoCamp has opened a new camping destination near Utah’s Zion National Park. A 16-acre property, AutoCamp Zion is located between the Virgin River and the desert of Southern Utah.

Concrete Technology | Apr 24, 2023

A housing complex outside Paris is touted as the world’s first fully recycled concrete building

Outside Paris, Holcim, a Swiss-based provider of innovative and sustainable building solutions, and Seqens, a social housing provider in France, are partnering to build Recygénie—a 220-unit housing complex, including 70 social housing units. Holcim is calling the project the world’s first fully recycled concrete building.

Design Innovation Report | Apr 19, 2023

Reinforced concrete walls and fins stiffen and shade the National Bank of Kuwait skyscraper

When the National Bank of Kuwait first conceived its new headquarters more than a decade ago, it wanted to make a statement about passive design with a soaring tower that could withstand the extreme heat of Kuwait City, the country’s desert capital.

Design Innovation Report | Apr 19, 2023

HDR uses artificial intelligence tools to help design a vital health clinic in India

Architects from HDR worked pro bono with iKure, a technology-centric healthcare provider, to build a healthcare clinic in rural India.

Urban Planning | Apr 12, 2023

Watch: Trends in urban design for 2023, with James Corner Field Operations

Isabel Castilla, a Principal Designer with the landscape architecture firm James Corner Field Operations, discusses recent changes in clients' priorities about urban design, with a focus on her firm's recent projects.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.