The buckling restrained braced frame system was introduced to the U.S. construction market in 1999 as a solution for meeting hardened building codes following the 1994 Northridge earthquake. Since then, BRBF has been used to stabilize hundreds of buildings along the West Coast, especially in earthquake-prone California.

As seismic codes play a larger role in building projects east of the Sierras, Building Teams across the country are turning to seismic design solutions like BRBF that were perfected in the West to meet increasingly stringent code requirements.

The latest example is the five-story, 179,000-sf Adult Behavioral Health Center, recently completed as part of the Dormitory Authority of the State of New York’s rebuilding of the Bronx Psychiatric Center campus, on behalf of the New York State Office of Mental Health.

Unlike many large-scale New York City structures built on solid rock foundations, the 156-bed Bronx healthcare facility is situated on wetlands that had been filled in with four million cubic yards of material generated from the construction of the Cross Bronx Expressway from 1948 to 1972. The poor soil conditions resulted in a Site Class F categorization and a Seismic Design Category D for the site. It called for an expanded geotechnical investigation and assessment, as well as seismic mitigation measures that were recently implemented under the New York State Building Code.

Situated on wetlands, the five-story, 179,000-sf Adult Behavioral Health Center in the Bronx, N.Y., required special seismic mitigation measures. Buckling restrained braces were the most economical, efficient solution.

Situated on wetlands, the five-story, 179,000-sf Adult Behavioral Health Center in the Bronx, N.Y., required special seismic mitigation measures. Buckling restrained braces were the most economical, efficient solution.

The structural design team, led by STV, first considered a traditional concentric braced frame lateral system. The solution met seismic requirements, but posed space-planning concerns for the client. Its relatively sizable structural elements and supporting walls would have bumped up against the health center’s programmatic requirements for rooms and circulation and would have jeopardized the architect’s open, airy indoor design scheme.

The final design approach, developed in conjunction with engineers in STV’s Los Angeles office, called for a BRBF system—a first for the Northeast—to enhance the structural performance of the building and greatly reduce steel frame member sizes. It also minimized the number of supporting walls needed for the project, and saved approximately $500,000 in material costs, according to Chris Cerino, PE, SECB, VP and Director of Structural Engineering, Building & Facilities Division, with STV. The firm also served as the design architect and electrical, civil, geotechnical, and telecom engineer on the project.

With the BRBF approach, certain braced frame steel columns could be downsized from W14x426 to W14x342, and select braced frame steel beams were reduced from W36x150 to W24x68.

“Smaller frame members gave STV designers flexibility in considering the movement of staff, residents, and food and building services,” says Cerino. “It also improved sightlines in all staff and resident areas to reduce the dependency on electronic monitoring.”

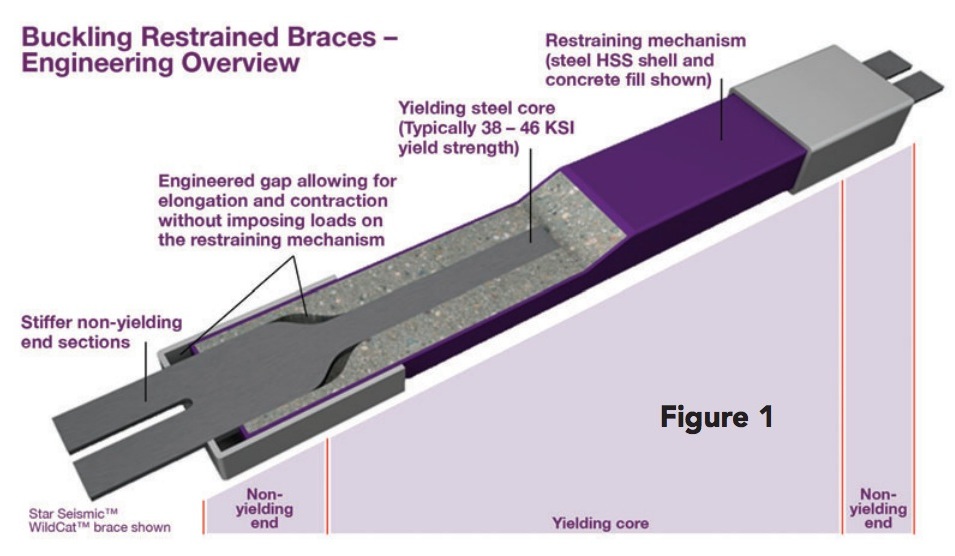

Buckling restrained braces (BRBs) vary slightly based on the manufacturer, but all BRBs include five basic components: a steel-plate core shaped like a kayak paddle (1) is placed within a hollow steel tube (2) that is coated with a low-friction material (3), which is then grouted in place (4) and capped (5). The grouted steel tube design prevents the steel core from buckling when in compression, while the coating prevents axial load from being transferred to the encasement.

The result is a “full, balanced response in relation to the forces being applied,” says Cerino. “Because the steel core is restrained, it develops nearly uniform axial strains across the section, resulting in efficient energy dissipation.”

This balanced energy dissipation, in turn, permits design teams to use much smaller beam sizes than with a standard braced frame.

On the Adult Behavioral Health Center project, Cerino’s team specified a proprietary system manufactured by Star Seismic. According to Cerino, Star’s Wildcat BRB system, which features single-pin connections, reduced erection time because it eliminated the need for stiffener plates. “Its patented collar reduces welding, since simple fillets can be used,” says Cerino. “That factored into the overall monetary savings.”

Cerino offers a few tips for Building Teams evaluating BRBFs:

- Watch out for the added special seismic requirements and details that become triggered when using a high-performance seismic system. “Not that a BRBF has different triggers than a special concentrically braced frame system, but since much of the design is deferred to the specialty brace contractor, some of the details can become out of sight, out of mind,” he says.

- Decide on the system early so you can address any client/procurement obstacles. “If it becomes too late, it can simply be easier to do nothing,” says Cerino. “That doesn’t help the project.”

Buckling restrained braces include several basic components: a steel-plate core is placed within a hollow steel tube that is coated with a low-friction material and then grouted in place and capped. The grouted steel tube design prevents the steel core from buckling when in compression, while the coating prevents axial load from being transferred to the encasement.

Buckling restrained braces include several basic components: a steel-plate core is placed within a hollow steel tube that is coated with a low-friction material and then grouted in place and capped. The grouted steel tube design prevents the steel core from buckling when in compression, while the coating prevents axial load from being transferred to the encasement.

Related Stories

Building Tech | Feb 17, 2021

PCL Construction introduces The PURE Portal for quickly sanitizing surfaces

The solution uses FAR-UV light technology.

Contractors | Dec 4, 2020

‘Speed to market’ defines general contractor activities in 2020

Contractors are more receptive than ever to ways that help get projects done faster.

Smart Buildings | Nov 20, 2020

The Weekly show: SPIRE smart building rating system, and pickleball court design tips

The November 19 episode of BD+C's The Weekly is available for viewing on demand.

AEC Tech | Oct 28, 2020

Meet Jaibot, Hilti's new construction robot

The semi-autonomous robot is designed to assist MEP contractors with ceiling-drilling applications.

Smart Buildings | Oct 26, 2020

World’s first smart building assessment and rating program released

The SPIRE Smart Building Program will help building owners and operators make better investment decisions, improve tenant satisfaction, and increase asset value.

Building Tech | Jun 16, 2020

thyssenkrupp Elevator launches forward-looking technologies for a more comfortable and secure mobility experience

To ensure peace of mind for passengers, the company is focusing on three pillars: hygiene, social distancing and touchless technologies.

Healthcare Facilities | Mar 9, 2020

Mobile wayfinding platform helps patients, visitors navigate convoluted health campuses

Gozio Health uses a robot to roam hospital campuses to capture data and create detailed maps of the building spaces and campus.

University Buildings | Mar 9, 2020

Auburn University, Robins & Morton open Construction Field Laboratory

Robins & Morton and Auburn University’s College of Architecture, Design and Construction (CADC) recently celebrated the dedication of the Robins & Morton Construction Field Laboratory.

Green | Mar 9, 2020

BuroHappold commits to all new building projects achieving net-zero carbon by 2030

The engineering firm also launched a long-term partnership with ILFI.

Modular Building | Feb 16, 2020

On the West Coast, prefab gains ground for speedier construction

Gensler has been working with component supplier Clark Pacific on several projects.