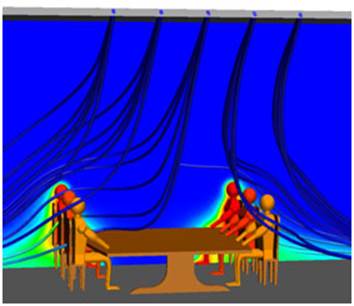

A misperception about computational fluid dynamics is that it is only effective when designing a jet plane, a formula one car, or an outer space rocket. Today, building designers can apply the same basic principles in fluid dynamics tested on these exotic high-flyers to common building airflows.

Here are three reasons why you might consider CFD for your next building project.

1. Best guess approach — Although guided by ASHRAE standards, current HVAC specs are usually “best guesses” based on experience with various equipment and designs. Most engineers oversize HVAC units because they just don’t “know” exactly where thermal differentials including cyclic variations, radiant temperature asymmetries, and drafts will happen in an operating building. Using CFD insight, you can right-size HVAC solutions to eliminate redundant equipment and save costs.

2. BIM modeling is standard — The widespread adoption of BIM has led to an unprecedented ability to model new designs. Now, engineers and designers routinely run time and light studies, finite element analyses and energy efficiency studies working with the BIM model. The extension of a building model to CFD analysis is not the leap it may have been ten years ago. Now, airflow designers can run through a number of scenarios for ventilation and heating using different strategies inside the actual building model.

5 benefits of CFD analysis

1. Assess ventilation effectiveness before construction

2. Eliminate equipment redundancy

3. Weigh equipment costs against performance and environmental requirements

4. Substantiate performance claims

5. Locate supply/return for optimal airflow

3. Seeing is believing — CFD analyses produce easy to understand visuals that show the impact of design alternatives, allowing architects to move walls, alter service conduit pathways and change glazing effects—among other things—to improve energy efficiency and occupant comfort. These visuals are crucial in explaining to owners the impact of design changes, airflow strategies and or equipment purchases. When everyone can easily grasp the results of the sophisticated math behind CFD, you can reach agreement more quickly and with a higher level of confidence.

Typically, designers do not have the time, knowledge or technology to perform a CFD analysis. The alternative is to work with outsourced CFD experts to generate the best airflow strategy for your project. The key here is to find the right fit. Make sure your CFD supplier has a demonstrated range of experience with the kind of building you are designing.

Your CFD partners should recognize precisely how to properly model an environment to reveal key performance insights—thermal stratification and restricted flows, for example. In addition, your CFD consultant should be collaborative—working with the design team to explore options for improvement.

No matter what kind of project you are designing—a new manufacturing plant, a new residential building or healthcare institution, or a retrofit of a landmark office complex—a proper CFD analysis will save money in initial capital costs and far more over time in building operating and energy costs. As a designer, you can provide your client with a better, less expensive solution.

About the Author

Jason Pfeiffer is Director CFD Analysis Consulting with IMAGINiT Technologies. He can be reached at jpfeiffer@rand.com.

Related Stories

| Mar 29, 2012

Roller shade operating system wins IF Product Design Award

Design experts in the iF jury recognized the engineering invested in the RB 500 Roller Shade, including a metal clutch with a patented construction, a durable zamac housing with polished finish, and a chain drive unit that excels in maximum operating comfort.

| Mar 29, 2012

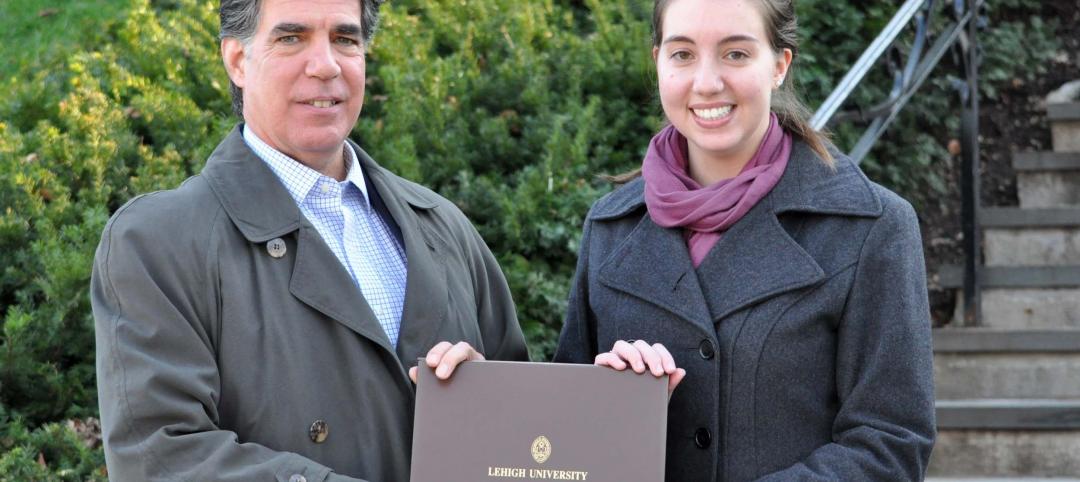

Lehigh engineering student wins Thornton Tomasetti Foundation Awards Scholarship

The scholarship is awarded annually to a graduate student in structural engineering deemed by the department to have the potential to make an impact in the field professionally.

| Mar 29, 2012

Construction completed on Las Vegas’ newest performing arts center

The Smith Center will be the first major multi-purpose performance center in the U.S. to earn Silver LEED certification.

| Mar 29, 2012

Apartments provide permanent housing for California homeless

Gonzalez Goodale Architects designed complex to embrace community and engender sense of pride among residents.

| Mar 28, 2012

40 Under 40, the Class of 2012

Chosen from 223 applicants, these 40 young AEC professionals represent the Class of 2012 in Building Design+Construction’s “40 UNDER 40” competition.

| Mar 28, 2012

Milestone reached for LEED-certified buildings?

Total number of major global green buildings now stands at 12,000.

| Mar 28, 2012

Holden Cancer Center opens at University of Iowa Hospitals and Clinics

The new cancer clinic provides a significant increase in patient space from the prior facility, which was located in an adjacent building.

| Mar 28, 2012

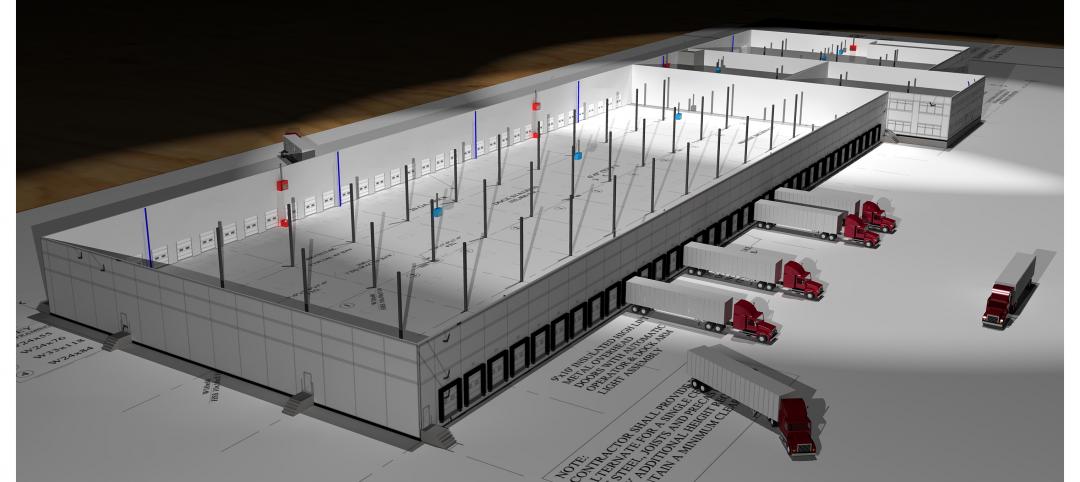

Meridian Design Build Begins work on 38 acre redevelopment project

The project includes construction of a new 150,585-sf cross dock facility that will include full service truck maintenance and repair bays, a truck wash, and approximately 20,000-sf of corporate office space.

| Mar 28, 2012

Tsoi/Kobis & Associates developing master plan for UT Southwestern Medical Center

Firm will spearhead strategies for transforming existing in-patient hospital into state-of-the-art ambulatory care facility.

| Mar 28, 2012

Ideas and input drive stories in online community, noraXchange

Community designed to help building and design professionals address challenges they face in their jobs.