London-based design firm Bryden Wood, with offices in Singapore, Barcelona, and Milan, will bolster its presence in the United States when it opens new headquarters in Boston this summer.

Founded in 1995, the firm now specializes in a value-oriented kit-of-parts “Platform” approach to design for manufacturing and assembly (DfMA). Bryden Wood’s North American expansion is being led by directors Jaimie Johnstone and Phil Langley, its head of global systems and creative technologies, respectively.

In an interview with BD+C last week, Johnston said that Bryden Wood’s plans to expand into the U.S. in 2020 were postponed because of the coronavirus pandemic. Prior to its moving into Boston, Bryden Wood had done some work in the U.S. for the pharmaceutical firm GlaxoSmithKline. Among the AEC and service-provider firms currently teaming with Bryden Wood on industrial projects in the U.S. are The Boldt Company, Amazon Web Services, and DPR Construction.

The timing of its expansion, said Johnston, was motivated by the slow-moving pace in the U.K. toward adopting offsite manufacturing as an element of commercial construction. “There have been pockets of excellence, but also more of a focus on volumetric modular for homebuilding.” The opposite is occurring in the U.S., he observed, where nonresidential developers and their AEC have been embracing prefabrication. Bryden Wood’s goal is to establish a North American supply network for industrial components.

Johnston noted that while “a lot of people” in the U.S. are prefabricating MEP components, that competitive advantage “can be diluted over time.” What Bryden Wood offers, he explained, is a merging of volumetric design with manufacturing for better and quicker results.

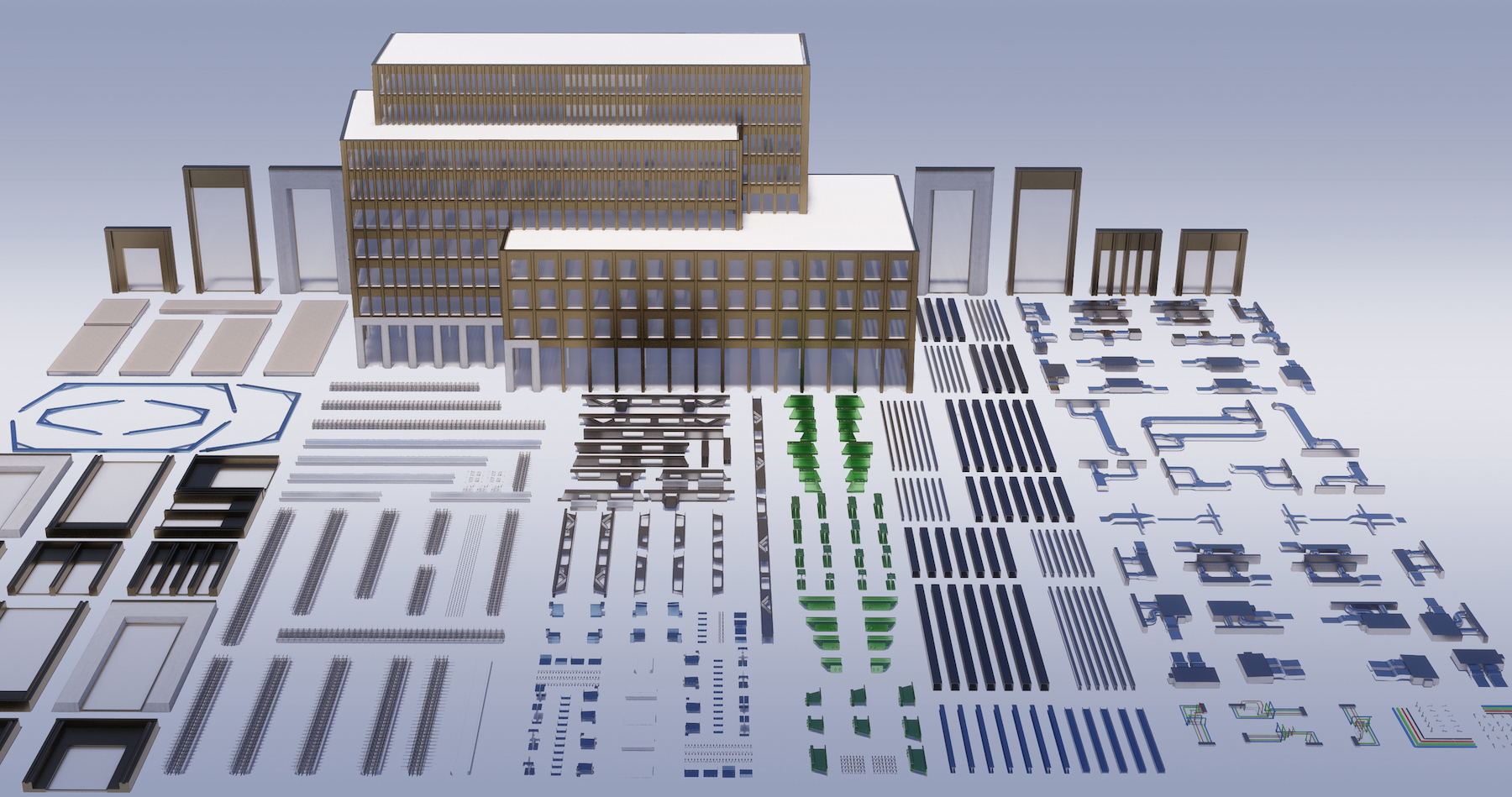

Bryden Wood’s Platform approach standardizes manufactured components that are made offsite and assembled onsite, thereby assuring greater certainty about schedules and budgets. Platforms also embed materials reuse and reductions in carbon into early stages of design.

The firm works with tech clients to develop design technologies such as “digital configurators” that rely on genetic algorithms to generate thousands of design and engineering solutions for sites around the world. By developing solutions that allow appropriate levels of repeatability in such building types as data centers, without sacrificing quality, “we’re helping [clients] transform their businesses,” said Johnston in a prepared statement.

THE FORGE SHOWCASES PLATFORM-DRIVEN SAVINGS

The Forge has been much quicker and more accurate.

The first major commercial project being delivered using the Platform approach to DfMA is The Forge, which topped out last December, and is scheduled for completion in the fourth quarter of this year. The Forge is comprised of two sustainably focused nine-story commercial buildings—90,000 and 49,000 sf, respectively—in central London, built around an accessible courtyard. Its projected efficiencies include a nearly 20 percent reduction in embodied carbon per square meter, a 36.4 percent reduction in the substructure, and a 20.2 reduction in superstructure and façade materials. Johnston said that the buildings’ façade panels could be installed in just 7½ minutes each, and with greater accuracy.

The Forge’s developer, Landsea, anticipates a 9.5 percent reduction in capital costs from this platform kit-of-parts approach. The Forge is also the U.K’s first net-zero energy project. The building team includes a joint venture between the construction firms Sir Robert McAlpine and Mace, and NG Bailey as the MEP engineer.

Johnston expected Bryden Wood to focus its attention in North American on projects for healthcare, data centers, pharma, and industrial, “wherever there’s a high degree of complexity and repetition.” On its website, Bryden Wood said it has been designing data centers since 1999, and has been delivering 30-40 percent reductions in capital build costs per kilowatt, and an average 40 percent increase in IT yield per square meter.

Scalability via industrialized construction for these building types is where clients are most likely to benefit from improvements in design and delivery, the firm contended. Johnston also foresaw Bryden Wood doing a bit more multifamily design in the U.S. than it does within its home market.

A few years ago, the firm launched a free-to-use and open-source housing design application called PRiSM that, it claims, brings together central and regional government, investors, developers, and manufacturers, with the goal of driving improved productivity and quality. The updated version of PRiSM incorporates Bryden Wood’s Platforms approach to DfMA.

Related Stories

Architects | Mar 5, 2024

Riken Yamamoto wins 2024 Pritzker Architecture Prize

The Pritzker Architecture Prize announces Riken Yamamoto, of Yokohama, Japan, as the 2024 Laureate of the Pritzker Architecture Prize, the award that is regarded internationally as architecture’s highest honor.

Office Buildings | Mar 5, 2024

Former McDonald’s headquarters transformed into modern office building for Ace Hardware

In Oak Brook, Ill., about 15 miles west of downtown Chicago, McDonald’s former corporate headquarters has been transformed into a modern office building for its new tenant, Ace Hardware. Now for the first time, Ace Hardware can bring 1,700 employees from three facilities under one roof.

Green | Mar 5, 2024

New York City’s Green Economy Action Plan aims for building decarbonization

New York City’s recently revealed Green Economy Action Plan includes the goals of the decarbonization of buildings and developing a renewable energy system. The ambitious plan includes enabling low-carbon alternatives in the transportation sector and boosting green industries, aiming to create more than 12,000 green economy apprenticeships by 2040.

Lighting | Mar 4, 2024

Illuminating your path to energy efficiency

Design Collaborative's Kelsey Rowe, PE, CLD, shares some tools, resources, and next steps to guide you through the process of lighting design.

MFPRO+ News | Mar 1, 2024

Housing affordability, speed of construction are top of mind for multifamily architecture and construction firms

The 2023 Multifamily Giants get creative to solve the affordability crisis, while helping their developer clients build faster and more economically.

Multifamily Housing | Feb 29, 2024

Manny Gonzalez, FAIA, inducted into Best in American Living Awards Hall of Fame

Manny Gonzalez, FAIA, has been inducted into the BALA Hall of Fame.

K-12 Schools | Feb 29, 2024

Average age of U.S. school buildings is just under 50 years

The average age of a main instructional school building in the United States is 49 years, according to a survey by the National Center for Education Statistics (NCES). About 38% of schools were built before 1970. Roughly half of the schools surveyed have undergone a major building renovation or addition.

MFPRO+ Research | Feb 28, 2024

New download: BD+C's 2023 Multifamily Amenities report

New research from Building Design+Construction and Multifamily Pro+ highlights the 127 top amenities that developers, property owners, architects, contractors, and builders are providing in today’s apartment, condominium, student housing, and senior living communities.

AEC Tech | Feb 28, 2024

How to harness LIDAR and BIM technology for precise building data, equipment needs

By following the Scan to Point Cloud + Point Cloud to BIM process, organizations can leverage the power of LIDAR and BIM technology at the same time. This optimizes the documentation of existing building conditions, functions, and equipment needs as a current condition and as a starting point for future physical plant expansion projects.

Data Centers | Feb 28, 2024

What’s next for data center design in 2024

Nuclear power, direct-to-chip liquid cooling, and data centers as learning destinations are among the emerging design trends in the data center sector, according to Scott Hays, Sector Leader, Sustainable Design, with HED.