The construction engineering firm Clayco is vetting manufacturers to produce what it’s calling the “hard hat of the future,” which Clayco has developed with a team of 14 students and two faculty members at the Savannah (Ga.) College of Arts and Design (SCAD).

The global hard-hat market is expected to hit $3.19 billion in sales in 2025, from $2.1 billion in 2016. Clayco has been investigating improvements in hard-hat design for more than a year, starting with a evaluation of different design trends worldwide. “We concluded that we might be better off designing a new helmet ourselves,” says Todd Friis, Clayco’s Vice President of Risk Management.

Clayco had been involved in numerous construction projects with SCAD, and also supports the school’s sustainability efforts, says Paul Runko, Collaboration Manager at SCADpro, the school’s industry partnership department.

To gain a better understanding on how construction workers use their hard hats, the students visited Clayco’s jobsite for a 14-story residence hall at SCAD’s Atlanta campus to observe and interview the labor. “For many of our students, this was the first time they had ever put on a hard hat,” says Runko.

SCAD also created an online survey that received 188 responses from workers at various locations around the country.

What the research found was that while existing hard hats are safe, too often workers aren’t wearing them because, they say, the hats are uncomfortable or too hot. What the student team also discovered was how avidly workers personalize their hats, usually with stickers. And many of the workers polled or interviewed wear sunglasses on the job, which can affect the wearability of the helmets.

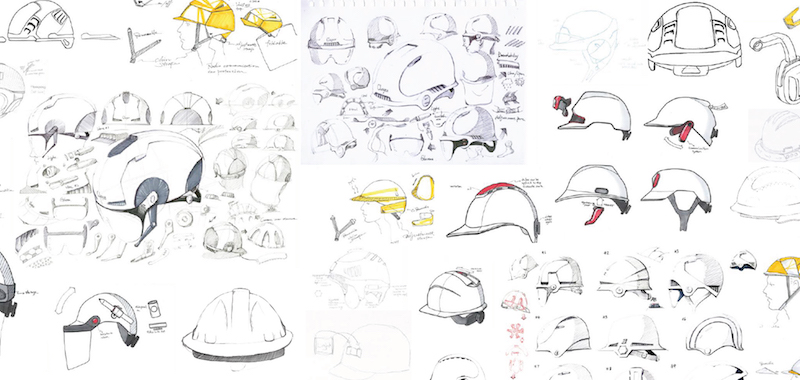

Charu Pardasani a researcher, planner, and documentarian on the Clayco-SCAD team, says that the students came up with 10 conceptual and abstract ideas, from which they developed eight hard hat concepts. Clayco has selected two prototypes on which to move forward:

Clayco has selected two hard hat designs, The Captain and Pollux, to manufacture. These were chosen from eight concepts. Image: Clayco

Pollux, whose design was based on workers’ need for adaptability. The customizable design allows users to attach a magnetic LED light or mount a GoPro camera. Pollux has a rotatable, transparent full brim that provides shade and visibility. The prototype includes a chin strap, not exactly a feature workers were clamoring for, but one that is included to enhance users’ comfort and to keep the hats on their heads, especially in high-wind situations.

Captain, the second prototype, features a completely different design. It’s more like a helmet, with vents at the top and the brim. This hat also has portals for multiple accessory attachments.

Friis says that, in choosing these two models, Clayco considered weight, ventilation, lighting, and attachments. (Neither of the prototypes has a face shield, but one can be attached to each.) He adds that Clayco paid particular attention to back-of-head protection during the design phase.

The cost of the new hard hats, and when they might be available for sale, has yet to be determined. Runko notes that during the 10-week design period, a group of students was dedicated to selecting materials with an eye toward affordability.

Clayco’s involvement can be seen as part of its broader effort to improve jobsite safety. That effort got a boost from a $1 million five-year grant that Clayco and the Washington University School of Medicine in St. Louis received from the National Institute of Occupational Safety and Health and CPWR The Center for Construction Research and Training.

In 2013-2014, Clayco and the school had conducted a study of three of Clayco’s jobsites in St. Louis to observe and measure how ergonomic programs were being administered and complied with. Ann Marie Dale, an Associate Professor at the medical school, explains that ergonomic injuries occur over time from the gradual and repetitive wear and tear on the body. They can include such injuries as lower-back strain, rotator cuff tears, and trigger finger deterioration.

After seeing the results of this survey, Dale and Friis met in the spring of 2017 to discuss “interventions” that might help reduce such injuries. A program for that purpose was rolled out to all of Clayco’s job sites over the course of the following year. Dale and her team continued to monitor progress at the three “control” jobsites in St. Louis. (She was accompanied on jobsites by ergonomics experts who could answer workers’ questions.)

Dale says that it took longer than anticipated to develop the safety literature to disseminate to the jobsites, as well as a training regimen. “This is not going to be a quick fix,” she concedes. Friis declined to disclose specific data about jobsite safety except to say that, as of May 2019, three-quarters of Clayco’s active construction projects were injury-free. “It’s not perfect, but the results speak for themselves.”

Dale adds that there is interest among other construction companies to adopt the Model program that UWash and Clayco have developed.

Related Stories

MFPRO+ News | Feb 15, 2024

Nine states pledge to transition to heat pumps for residential HVAC and water heating

Nine states have signed a joint agreement to accelerate the transition to residential building electrification by significantly expanding heat pump sales to meet heating, cooling, and water heating demand. The Memorandum of Understanding was signed by directors of environmental agencies from California, Colorado, Maine, Maryland, Massachusetts, New Jersey, New York, Oregon, and Rhode Island.

MFPRO+ News | Feb 15, 2024

Oregon, California, Maine among states enacting policies to spur construction of missing middle housing

Although the number of new apartment building units recently reached the highest point in nearly 50 years, construction of duplexes, triplexes, and other buildings of from two to nine units made up just 1% of new housing units built in 2022. A few states have recently enacted new laws to spur more construction of these missing middle housing options.

Green | Feb 15, 2024

FEMA issues guidance on funding for net zero buildings

The Federal Emergency Management Agency (FEMA) recently unveiled new guidance on additional assistance funding for net zero buildings. The funding is available for implementing net-zero energy projects with a tie to disaster recovery or mitigation.

Hospital Design Trends | Feb 14, 2024

Plans for a massive research hospital in Dallas anticipates need for child healthcare

Children’s Health and the UT Southwestern Medical Center have unveiled their plans for a new $5 billion pediatric health campus and research hospital on more than 33 acres within Dallas’ Southwestern Medical District.

Contractors | Feb 13, 2024

The average U.S. contractor has 8.4 months worth of construction work in the pipeline, as of January 2024

Associated Builders and Contractors reported today that its Construction Backlog Indicator declined to 8.4 months in January, according to an ABC member survey conducted from Jan. 22 to Feb. 4. The reading is down 0.6 months from January 2023.

Codes | Feb 9, 2024

Illinois releases stretch energy code for building construction

Illinois is the latest jurisdiction to release a stretch energy code that provides standards for communities to mandate more efficient building construction. St. Louis, Mo., and a few states, including California, Colorado, and Massachusetts, currently have stretch codes in place.

Giants 400 | Feb 8, 2024

Top 10 Telecommunications Building Construction Firms for 2023

AECOM, LeChase Construction Services, Robins & Morton, and Salas O'Brien top BD+C's ranking of the nation's largest telecommunications building general contractors and construction management (CM) firms for 2023, as reported in Building Design+Construction's 2023 Giants 400 Report.

Giants 400 | Feb 8, 2024

Top 20 Integrated Project Delivery (IPD) Construction Firms for 2023

Barton Malow, DPR Construction, Hensel Phelps, and Whiting-Turner top BD+C's ranking of the nation's largest integrated project delivery (IPD) construction firms for 2023, as reported in Building Design+Construction's 2023 Giants 400 Report.

Giants 400 | Feb 8, 2024

Top 90 Design-Build Construction Firms for 2023

Hensel Phelps, Ryan Companies US, Gray Construction, Haskell, and Burns & McDonnell top BD+C's ranking of the nation's largest design-build construction firms for 2023, as reported in Building Design+Construction's 2023 Giants 400 Report.

Giants 400 | Feb 8, 2024

Top 20 Public Library Construction Firms for 2023

Gilbane Building Company, Skanska USA, Manhattan Construction, McCownGordon Construction, and C.W. Driver Companies top BD+C's ranking of the nation's largest public library general contractors and construction management (CM) firms for 2023, as reported in Building Design+Construction's 2023 Giants 400 Report.