For the 2018 AIA Convention and Trade Show, Building, Design + Construction magazine debuted its Design Showcase exhibit—a one-of-a kind tiny house, representing the “Workplace of the Future.” This unique structure, designed and constructed by Tiny House Northeast saw more than 1000 visitors during the two-day trade show, which was held in New York in June.

As the exterior sponsor, ALPOLIC turned to Metal Design Systems (MDS) in Cedar Rapids, Iowa to come up with a way to fabricate its Timber Series metal composite material —finished in Walnut— for this unique venture. Unlike most ALPOLIC projects, the tiny house required an install capable of staying in place while the structure it was applied to was actually rolling down a highway.

“We had to really think outside the box on how the fabrication and installation would need to be because, by necessity, this was a very different application for MCM,” said MDS Project Manager Lee Velky.

To achieve the best results, Velky and the MDSI team fabricated nearly 1,000 square feet of ALPOLIC’s 3mm metal composite material into 10” x 12’ strips, and then hand rolled the bottom edge of each piece. They did a test run on a mock up inside the facility to ensure the product not only looked great, but installed as easily as they’d hoped. It did.

On site at the tiny house build, the Walnut MCM was layered, much like residential vinyl, with a one inch overlap, helping to create a water-resistant siding. And just like vinyl, the ALPOLIC material didn’t require special tools or equipment to install. Workers were able to cut, shape and trim the product to fit the home’s dimensions on site with regular carpentry tools.

“We were so pleased with the end result. It’s always exciting to see our product used in an innovative, creative way,” said David Kearney, sales and marketing director for ALPOLIC. “And, this obviously provides new design options for customers, both residential and commercial.”

Related Stories

Sponsored | Cladding and Facade Systems | Mar 15, 2023

Metal cladding trends and innovations

Metal cladding is on a growth trajectory globally. This is reflected in rising demand for rainscreen cladding and architectural metal coatings. This course covers the latest trends and innovations in the metal cladding market.

Codes | Mar 2, 2023

Biden Administration’s proposed building materials rules increase domestic requirements

The Biden Administration’s proposal on building materials rules used on federal construction and federally funded state and local buildings would significantly boost the made-in-America mandate. In the past, products could qualify as domestically made if at least 55% of the value of their components were from the U.S.

AEC Innovators | Feb 28, 2023

Meet the 'urban miner' who is rethinking how we deconstruct and reuse buildings

New Horizon Urban Mining, a demolition firm in the Netherlands, has hitched its business model to construction materials recycling. It's plan: deconstruct buildings and infrastructure and sell the building products for reuse in new construction. New Horizon and its Founder Michel Baars have been named 2023 AEC Innovators by Building Design+Construction editors.

Sponsored | Metals | Jan 16, 2023

Breaking The Mold: ALPOLIC MCM Accomplishes A+ Design for Ohio School

From the start, the vision for Dayton’s Northridge Local Schools included a standout architectural element. Taking inspiration from the polar bear mascot, Levin Porter Architects created an unforgettable iceberg feature with the help of ALPOLIC. Custom white MCM panels shimmer and provide a local landmark for the community.

75 Top Building Products | Nov 30, 2022

75 top building products for 2022

Each year, the Building Design+Construction editorial team evaluates the vast universe of new and updated products, materials, and systems for the U.S. building design and construction market. The best-of-the-best products make up our annual 75 Top Products report.

Sponsored | Metals | Nov 10, 2022

Largest Tulip Bulb Forcing Farm Rebuilds from Ground Up

Metl-Span insulated metal panels delivered the optimal solution for the new Pioneer Flower Farms facility to rebuild after a fire. The warehouse included the installation of movable freezers and cold storage areas.

Sponsored | Metals | Nov 9, 2022

Making a Difference: Lakeshore Lofts Brings Sustainability and Support with Inspiring Designs

Lakeshore Lofts sets a new standard for affordable housing providing expansive services and support and inspiring sustainable design made possible with ALPOLIC.

Building Materials | Nov 2, 2022

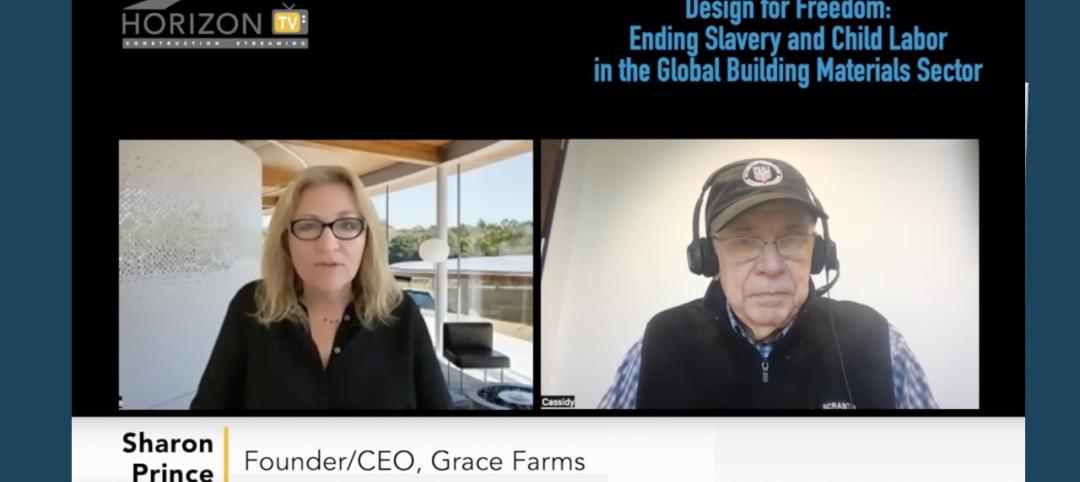

Design for Freedom: Ending slavery and child labor in the global building materials sector

Sharon Prince, Founder and CEO of Grace Farms and Design for Freedom, discusses DFF's report on slavery and enforced child labor in building products and materials.

Sponsored | Metals | Oct 13, 2022

The Benefits of Insulated Metal Panels Over Tilt-Up Walls

When it comes time to choose a building envelope material, project teams can select from a wide array of options. Tilt-up walls can offer some savings, but one system leads the industry for installation, energy, and cost efficiencies: Insulated metal panels.