We asked four veteran acoustics experts how best to sound- proof apartment and condo projects. Here’s what they told us.

1. Take acoustic privacy seriously. Noise complaints can end up in court. Make sure your project team pays careful attention to acoustics throughout design and construction. Developers should be engaged on how to improve acoustics at the design stage, so that they can provide accurate information to estimators. Good acoustics and noise control suggests a higher level of construction quality to the renter or condo buyer, said ACENTECH’s Ben Markham. This could have a positive effect on the perceived marketable value of the property.

2. Avoid noise problems in schematic designs. It’s import- ant to consider acoustics in the early stages of design when many potential problems—and remedial expense—can be avoided. Don’t put spaces that produce loud noises next to living units. Don’t put a fitness room next above apartments. Your tenants don’t want to hear the sound of pounding feet from a Zumba class.

3. Take your target market into account. Those who purchase or rent luxury properties expect superior acoustic privacy. Plan to spend more to accommodate their expectations. For market-rate and low-income units, more economical solutions may be adequate, provided that acoustic standards are followed in design and adhered to in construction. Affordable housing must meet acous- tic performance requirements set by the International Building Code, said Felicia Doggett, INCE Bd. Cert., Metropolitan Acoustics: for air- borne sound transmission, an STC (sound transmission class) of not less than 45 (field tested) under ASTM E 90 and 45 STC (under ASTM E 492) for structure-borne sound.

See Also: Say 'Hello' to erudite machines

4. Understand the impact of background sound levels. Background sounds created by moving vehicles or air flow from HVAC fans can sometimes mask noise from televisions or stereos being played at reasonable volume in adjoining units. On the other hand, a quiet location in a semi-rural area may offer little noise masking, in which case you may need a more robust sound iso- lation plan.

5. Isolate loud, low-pitched sounds. If your project is near a rail line, highway, or airport, you’ll need to beef up your acous- tics. Loud, low-frequency noises such as the rumble of trains, airplanes, and truck engine brakes are the most difficult to muffle. More mass, such as a concrete masonry wall, can provide a pretty good acoustic barrier, but it is better to construct multi-layer walls with deep cavities filled with sound-absorbing insulation. Windows and glazing should have multiple layers to reduce low-frequency noise intrusion. Interior storm windows, with a deep air gap between the inner storm window and the exterior thermal window, can bring the window system closer to the noise-reduction performance level of the wall itself, said AECOM’s Mark Storm, INCE Bd. Cert.

6. Be aware that building to code may not be good enough. Building codes offer little in the way of acoustic privacy. From an acoustics standpoint, our expert panelists agreed, building to code is like getting a D on a test. Don’t rely on conformance to codes alone to achieve acceptable acoustic performance.

7. Don’t overbuild. If you’re not up to speed on acoustic priva- 7|cy, you might be tempted to over-design and over-spend on acoustics. Many new products are being marketed as having acoustic damping qualities, but if you don’t fully understand how the product is meant to be used, you may end up using a pricier product than necessary to meet your soundproofing needs.

8. Consider having an acoustic expert perform a sound sim- ulation. This applies if you have a project with a high degree of fenestration near a major noise source such as a mass transit line. An acoustic specialist can simulate the indoor acoustic environ- ment based on multiple window options. Since the highest-perform- ing acoustic fenestration can cost four times that of standard prod- ucts, this simulation will help you choose the most economical option.

9. Consider hiring an acoustic consultant in certain situa- tions. This applies when you are planning to use a construc- tion type, floor/ceiling assembly, or mechanical system that you’re not 100% familiar with. An acoustic expert who knows those systems can save you a lot of time and money by helping you avoid remedial soundproofing.

10. Know your options on interior wall design. The most basic interior wall assembly consists of drywall at- tached to both sides of a single set of studs. Resilient channels (Z-shaped metal strips), when installed properly between the sheetrock and studs, act as shock absorbers for sound waves. These are fairly effective and economic solutions when combined with sound-absorbing insulation. Unfortunately, incorrect installa- tion that degrades resilient channel performance is all too common.

When using this option, you need to have on-site inspection by someone who is well versed in its proper installation. Resilient chan- nels are not effective when plywood must be placed between drywall and studs as a shear panel. Sandwiching a resilient channel between a plywood shear panel and a sheet of gypsum board on a wall assem- bly is a big no-no, according to our experts.

A common design for more robust acoustic performance is to use a double wall with two rows of studs separated by an inch or so of sound-absorbing insulation in the void. This arrangement takes up more space and costs more, but is much more effective at reducing noise between units. Very high-end projects might separate the frame assemblies with a layer of masonry for additional sound privacy.

In addition, a wide range of new resilient elements and sound-damp- ing products is now available. These include resilient clips, laminated drywall, and damping compounds, all of which reduce the transmis- sion through layers of sheathing.

11. Understand floor/ceiling acoustic principles. Floor/ ceiling assemblies must isolate sounds from within units, but have the added responsibility to muffle footsteps to the space below. Footsteps create impact vibrations, which can be more difficult to isolate than even most airborne sounds.

The typical treatment employs an underlayment of material that can absorb vibrations from footfalls—usually rubber, cork, or fiber- glass—placed under the top layer of flooring. A key point to remem- ber is that the type of flooring used requires a specific type of under- layment. Footsteps create different sounds on vinyl, tile, and wood. Matching the material with the optimal underlayment is critical. Con- sult the manufacturer’s recommendations.

Different types of buildings—cast-in-place concrete towers, steel- framed mid-rises, and wood-framed four-story apartment build- ings—have very different floor/ceiling assemblies but all need some kind of material that can absorb the vibrations of pattering feet.

12. Be sure to seal all gaps. The same kinds of sealants that provide thermal insulation and vapor and smoke barriers between spaces also improve acoustic isola- tion. Any small cracks or holes that are not sealed act as channels that transmit sound. This problem can be especially acute in projects that convert very old buildings to residential units, where the original flooring has shrunk over the years due to moisture loss, leaving huge gaps between the boards. Acousticians often specify more flexible, non-hardening sealants to close the gaps between the edges of an interior wall and another room surface, said AECOM’s Storm.

13. Minimize noise from mechanical and electrical sys- tems. HVAC manufacturers test their systems for noise, thus providing data that acousticians use to develop appropriate noise-control and sound-abatement measures. Ideally, mechanical equipment selected should operate at the point of highest efficiency: a fan should operate at or close to its most aero- dynamically efficient point. Low efficiency means the fan’s blades are spinning but less work is realized, which means more turbulence that produces unnecessary noise. The same goes for pumps and compres- sors. Try to select mechanical equipment so that it normally runs on lower speeds, unless higher speeds move the blade passage frequency into a range that’s easier to abate with acoustical absorption.

Related Stories

| Dec 20, 2013

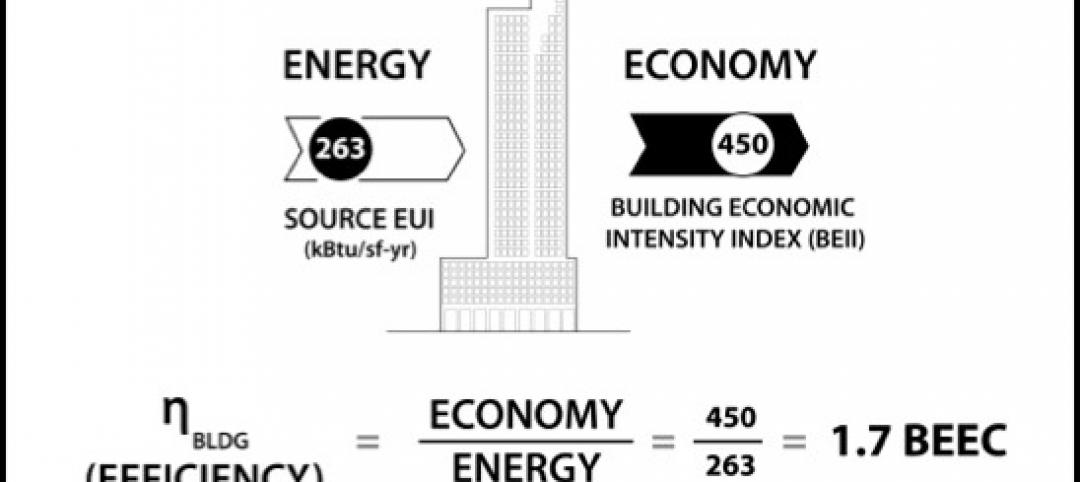

Can energy hogs still be considered efficient buildings? Yes, say engineers at Buro Happold

A new tool from the engineering firm Buro Happold takes into account both energy and economic performance of buildings for a true measure of efficiency.

| Dec 13, 2013

Safe and sound: 10 solutions for fire and life safety

From a dual fire-CO detector to an aspiration-sensing fire alarm, BD+C editors present a roundup of new fire and life safety products and technologies.

| Dec 10, 2013

16 great solutions for architects, engineers, and contractors

From a crowd-funded smart shovel to a why-didn’t-someone-do-this-sooner scheme for managing traffic in public restrooms, these ideas are noteworthy for creative problem-solving. Here are some of the most intriguing innovations the BD+C community has brought to our attention this year.

| Dec 4, 2013

First look: Dubai's winning bid for World Expo 2020 [slideshow]

Dubai has been chosen as the site of the 2020 World Expo. HOK led the design team that developed the master plan for the Expo, which is expected to draw more than 25 million visitors from October 2020 through April 2021.

| Nov 27, 2013

Exclusive survey: Revenues increased at nearly half of AEC firms in 2013

Forty-six percent of the respondents to an exclusive BD+C survey of AEC professionals reported that revenues had increased this year compared to 2012, with another 24.2% saying cash flow had stayed the same.

| Nov 27, 2013

Wonder walls: 13 choices for the building envelope

BD+C editors present a roundup of the latest technologies and applications in exterior wall systems, from a tapered metal wall installation in Oklahoma to a textured precast concrete solution in North Carolina.

| Nov 26, 2013

Construction costs rise for 22nd straight month in November

Construction costs in North America rose for the 22nd consecutive month in November as labor costs continued to increase, amid growing industry concern over the tight availability of skilled workers.

| Nov 25, 2013

Building Teams need to help owners avoid 'operational stray'

"Operational stray" occurs when a building’s MEP systems don’t work the way they should. Even the most well-designed and constructed building can stray from perfection—and that can cost the owner a ton in unnecessary utility costs. But help is on the way.

| Nov 19, 2013

Top 10 green building products for 2014

Assa Abloy's power-over-ethernet access-control locks and Schüco's retrofit façade system are among the products to make BuildingGreen Inc.'s annual Top-10 Green Building Products list.

| Nov 15, 2013

Greenbuild 2013 Report - BD+C Exclusive

The BD+C editorial team brings you this special report on the latest green building trends across nine key market sectors.