A recent survey of AEC firms and real estate owners and developers found a strong majority that had deployed off-site construction in the previous 12 months and planned to utilize it to a greater extent going forward.

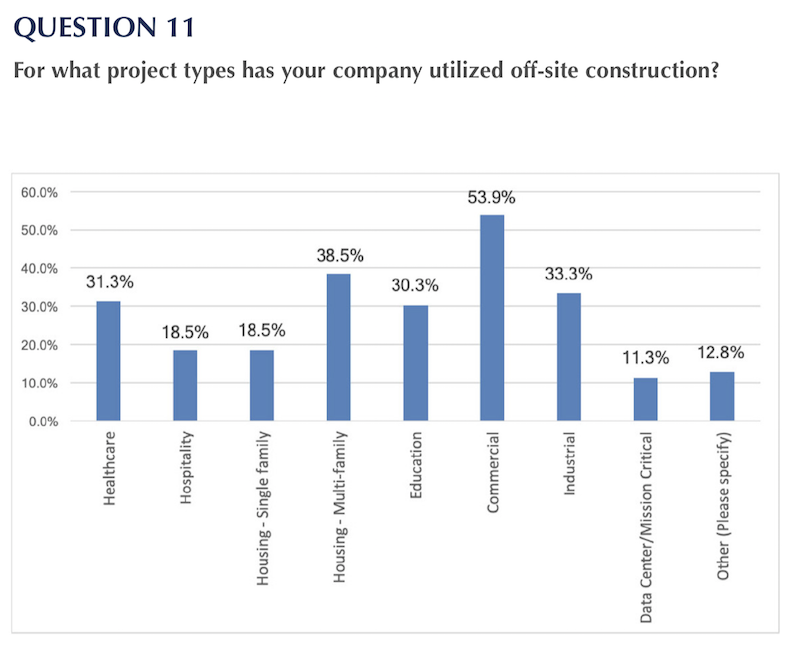

The Off-Site Construction Council of the National Institute of Building Sciences in Washington, D.C. conducted its 2018 Off-Site Construction Industry Survey as a follow-up to a 2014 survey to gauge the industry’s interest in off-site construction, which it defines as the planning, design, fabrication, and assembly of building elements at a location other than their final point of assembly onsite.

Ryan Smith of Washington State University and Kambaja Tarr of the University of Utah conducted and compiled the latest survey for NIBS.

“With the ongoing shortage of skilled craft workers (which exceeded two million in 2017), prefabrication in a controlled, off-site environment may become a necessity for many U.S. contractors attempting to remain competitive with a lower-skilled workforce,” the survey states. But as with any new process or technology innovation, and despite growing demand, ”uncertainties accompany the utilization of off-site construction.”

The commercial, multifamily and healthcare sectors are where off-site construction has been finding its greatest demand. Image: NIBS

A total of 205 participants responded to the 2018 Off-Site Construction Industry survey, versus 312 respondents to the 2014 poll. The participating companies provide a variety of different services, including construction management/general contracting (24.75% in 2018; 46.7% in 2014), engineering (21.72% and 38.3%), trade contracting (2.53% and 27.3%), architecture (87.88% and 15%), and owners/developers (10.1% and 8.3%).

Nearly nine of 10 respondents to the 2018 survey (87.72%) had used off-site fabricated components to some degree over the previous 12 months, and more than eight in 10 (81.63%) expected to engage off-site construction more often or the same amount in the following 12 months. (Both percentages were down slightly from the 2014 survey.)

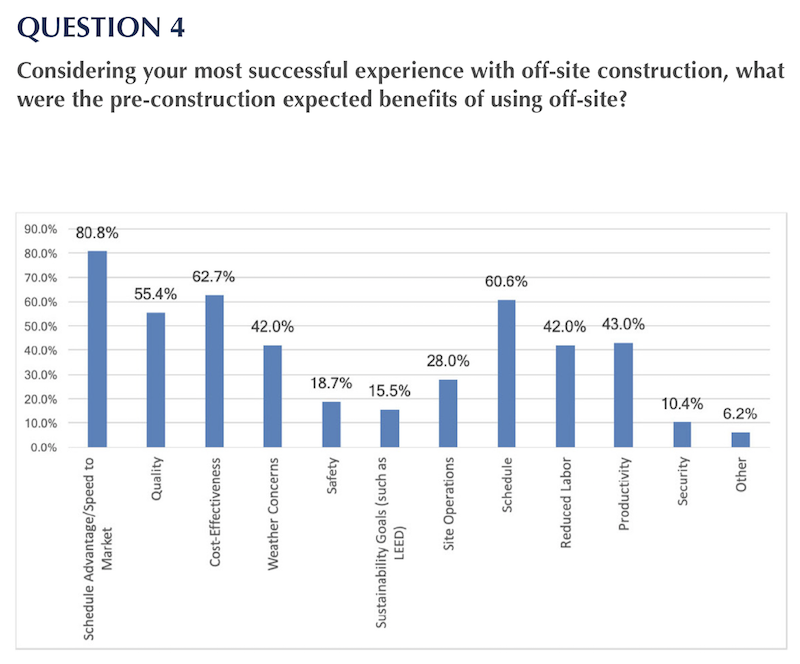

The primary benefit identified in both surveys is a reduced overall project schedule, specifically the duration of the construction phase.

For more than three fifths of respondents (63.22%) designers, architects and engineers were the primary decision makers about when off-site construction is implemented, followed by construction managers or general contractors (47.67%), clients (41.97%), and others, primarily subcontractors (21.24%).

Keeping projects on schedule is where companies that deploy off-site construction have been seeing the greatest benefit. Image: NIBS

Interestingly, however, respondents stated that the most significant barrier to off-site construction is the culture of design and construction in general. Comments indicated that late design changes, lack of collaboration and an adversarial climate for project delivery leads to difficulties in realizing the benefits of off-site construction.

The survey notes that the building component fabrication industry is still maturing and needs more time to integrate effectively with site-built work. In addition, contractors are still learning how to manage off-site products for assembly on-site.

Transportation is another significant barrier: specifically, how far away a factory is located from the construction site.

Respondents in both surveys qualitatively noted that some projects, particularly those with long spans, may not be suited for the use of pre-fabricated elements, and that each project has unique requirements that must be met through an appropriate technical solution.

Related Stories

Hotel Facilities | May 31, 2022

Checking out: Tips for converting hotels to housing

Many building owners are considering repositioning their hotels into another property type, such as senior living communities and rental apartments. Here's advice for getting started.

Museums | May 31, 2022

University of Texas at Dallas breaks ground on new 12-acre cultural district

The University of Texas at Dallas (UT Dallas) recently broke ground on the Crow Museum of Asian Art, the first phase of a new 12-acre cultural district on campus.

BAS and Security | May 26, 2022

Can your intelligent building outsmart hackers?

ESD's security services studio leader Coleman Wolf offers tips, advice, and lessons for protecting real estate assets from cyberattacks.

Sports and Recreational Facilities | May 26, 2022

WNBA practice facility will offer training opportunities for female athletes and youth

The Seattle Storm’s Center for Basketball Performance will feature amenities for community youth, including basketball courts, a nutrition center, and strength and conditioning training spaces.

Engineers | May 25, 2022

Epstein: The next 100 years

Multidisciplinary design and construction firm Epstein turned 100 in 2021. Two of its Directors discuss the firm's future, and what other AEC firms can learn from Epstein's experience. Darrin McCormies, Director of Industrial Services, and Ed Curley, AIA, Director of Architecture + Interiors, talk with BD+C's Rob Cassidy.

Multifamily Housing | May 25, 2022

9 noteworthy multifamily developments to debut in 2022

A 1980s-era shopping mall turned mixed-use housing and a mid-rise multifamily tower with unusual rowhomes highlight the innovative multifamily developments to debut recently.

Coronavirus | May 20, 2022

Center for Green Schools says U.S. schools need more support to fight COVID-19

The Center for Green Schools at the U.S. Green Building Council released a new report detailing how school districts around the country have managed air quality within their buildings during the second year of the COVID-19 pandemic.

Regulations | May 20, 2022

Biden’s Clean Air in Buildings Challenge aims to reduce COVID-19 spread

The Biden Administration recently launched the Clean Air in Buildings Challenge that calls on all building owners and operators, schools, colleges and universities, and organizations to adopt strategies to improve indoor air quality in their buildings and reduce the spread of COVID-19.

Building Team | May 20, 2022

Caltech breaks ground on a new center to study climate and sustainability

The California Institute of Technology (Caltech) recently broke ground on its Resnick Sustainability Resource Center.

Laboratories | May 20, 2022

Brutalist former Berkeley Art Museum transformed into modern life science lab

After extensive renovation and an addition, the former Berkeley Art Museum and Pacific Film Archive at the University of California, Berkeley campus reopened in May 2022 as a modern life science lab building.