A recent survey of AEC firms and real estate owners and developers found a strong majority that had deployed off-site construction in the previous 12 months and planned to utilize it to a greater extent going forward.

The Off-Site Construction Council of the National Institute of Building Sciences in Washington, D.C. conducted its 2018 Off-Site Construction Industry Survey as a follow-up to a 2014 survey to gauge the industry’s interest in off-site construction, which it defines as the planning, design, fabrication, and assembly of building elements at a location other than their final point of assembly onsite.

Ryan Smith of Washington State University and Kambaja Tarr of the University of Utah conducted and compiled the latest survey for NIBS.

“With the ongoing shortage of skilled craft workers (which exceeded two million in 2017), prefabrication in a controlled, off-site environment may become a necessity for many U.S. contractors attempting to remain competitive with a lower-skilled workforce,” the survey states. But as with any new process or technology innovation, and despite growing demand, ”uncertainties accompany the utilization of off-site construction.”

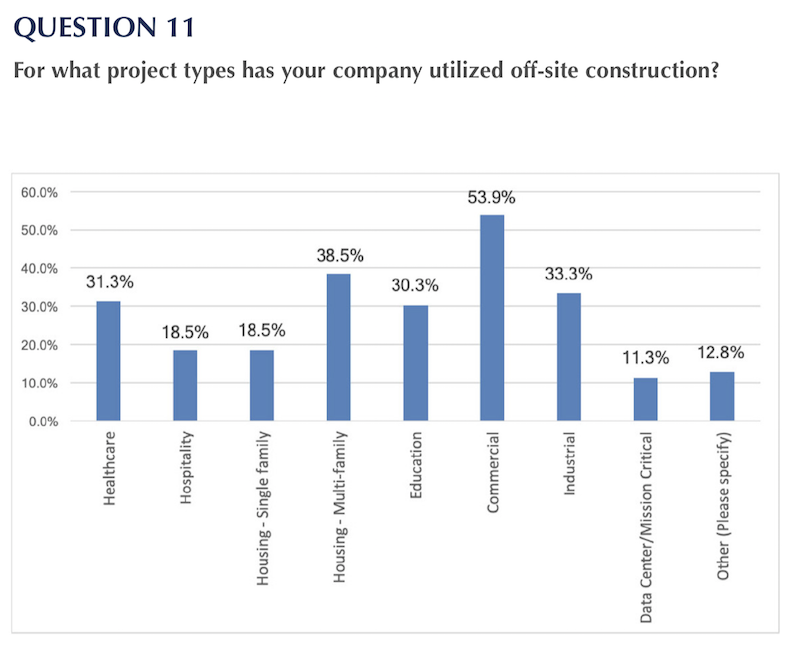

The commercial, multifamily and healthcare sectors are where off-site construction has been finding its greatest demand. Image: NIBS

A total of 205 participants responded to the 2018 Off-Site Construction Industry survey, versus 312 respondents to the 2014 poll. The participating companies provide a variety of different services, including construction management/general contracting (24.75% in 2018; 46.7% in 2014), engineering (21.72% and 38.3%), trade contracting (2.53% and 27.3%), architecture (87.88% and 15%), and owners/developers (10.1% and 8.3%).

Nearly nine of 10 respondents to the 2018 survey (87.72%) had used off-site fabricated components to some degree over the previous 12 months, and more than eight in 10 (81.63%) expected to engage off-site construction more often or the same amount in the following 12 months. (Both percentages were down slightly from the 2014 survey.)

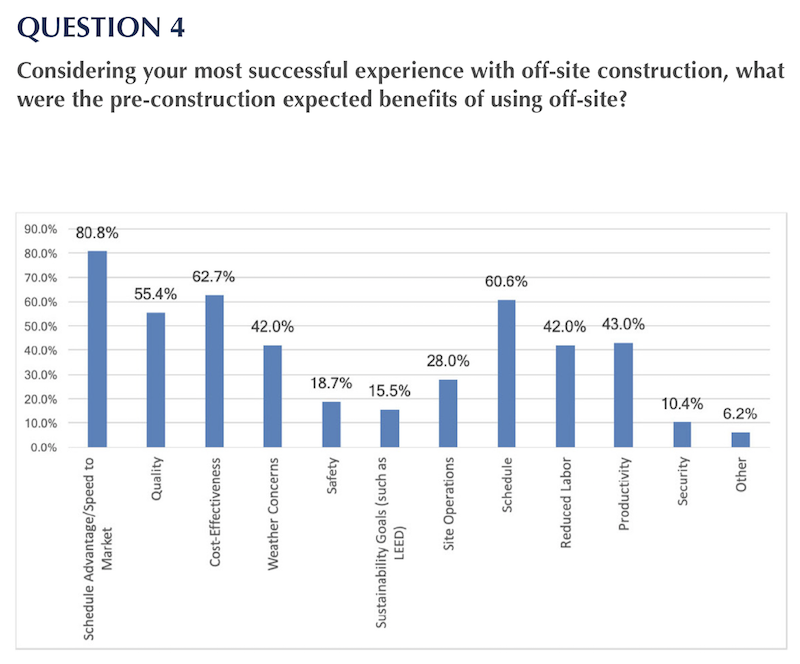

The primary benefit identified in both surveys is a reduced overall project schedule, specifically the duration of the construction phase.

For more than three fifths of respondents (63.22%) designers, architects and engineers were the primary decision makers about when off-site construction is implemented, followed by construction managers or general contractors (47.67%), clients (41.97%), and others, primarily subcontractors (21.24%).

Keeping projects on schedule is where companies that deploy off-site construction have been seeing the greatest benefit. Image: NIBS

Interestingly, however, respondents stated that the most significant barrier to off-site construction is the culture of design and construction in general. Comments indicated that late design changes, lack of collaboration and an adversarial climate for project delivery leads to difficulties in realizing the benefits of off-site construction.

The survey notes that the building component fabrication industry is still maturing and needs more time to integrate effectively with site-built work. In addition, contractors are still learning how to manage off-site products for assembly on-site.

Transportation is another significant barrier: specifically, how far away a factory is located from the construction site.

Respondents in both surveys qualitatively noted that some projects, particularly those with long spans, may not be suited for the use of pre-fabricated elements, and that each project has unique requirements that must be met through an appropriate technical solution.

Related Stories

| Aug 11, 2010

New building focuses on public safety

The $40 million public safety building for the city of El Cajon, Calif., is under construction and slated for completion in June 2011. The five-story, 119,400-sf building will house the city’s administrative offices, a joint police and fire emergency operations center, central data center, indoor firing range, crime lab, and short-term custody facility.

| Aug 11, 2010

MOB added to new hospital project

A late-2009 ground breaking is planned for a $20 million medical office building on the grounds of the $211 million, 106-bed Loma Linda University Medical Center in Murrieta, Calif., which itself is under construction. Minneapolis-based Frauenshuh HealthCare Real Estate Solutions is developing the five-story, 160,000-sf MOB, which will accommodate 60 physician offices.

| Aug 11, 2010

Firm goes for Gold with office design

DLR Group is designing its new Omaha, Neb., headquarters to achieve LEED Gold. Sustainable features being incorporated into the three-story, 39,000-sf building, which is part of the city’s new Aksarben Village mixed-use development, include daylighting, outdoor workspaces, native landscaping, a green roof, and the pursuit of renewable energy credits.

| Aug 11, 2010

BU students move into high-rise dorm

Boston University’s newest residential building rises 26 stories above the Charles River. Part of the school’s 10-acre John Hancock Student Village, the 396,000-sf tower houses 962 students and has three apartments for faculty use. The tower also has a large multipurpose room on the top floor.

| Aug 11, 2010

Mixed-use Seattle high-rise earns LEED Gold

Seattle’s 2201 Westlake development became the city’s first mixed-use and high-rise residential project to earn LEED Gold. Located in Seattle’s South Lake Union neighborhood, the newly completed 450,000-sf complex includes 300,000 sf of Class A office space, 135 luxury condominiums (known as Enso), and 25,000 sf of retail space.

| Aug 11, 2010

Theater offers spectacular views inside and out

A 500-seat proscenium theater sits at the heart of the 35,000-sf Performing Arts Pavilion at the Jackson Hole Center for the Arts. The entertainment and cultural facility, designed by Stephen Dynia Architects, Jackson Hole, Wyo., also houses glass-walled rehearsal rooms that offer passersby views of the activity going on inside and multifunction lobby with views of Snow King Mountain.

| Aug 11, 2010

Corporate campus gets LEED stamp of Gold

The new 100,000-sf corporate headquarters for The Thornburg Companies in Santa Fe, N.M., earned LEED Gold. Designed in the “new-old Santa Fe style” by Legorreta + Legorreta, with local firms Dekker/Perich/Sabatini and Klinger Constructors on the Building Team, the green building sits on seven acres and features three distinct but interconnected office spaces with two courtyards and ...

| Aug 11, 2010

Expansion of chemistry facility no experiment

A September ground breaking at Wayne State University in Detroit puts the school’s A. Paul Schaap Chemistry Building and Lecture Hall on track for a December 2010 completion. The $37 million, 96,000-sf facility is the second phase of a two-phase project to expand and renovate the existing chemistry building.

| Aug 11, 2010

Design for Miami Art Museum triples gallery space

Herzog & de Meuron has completed design development for the Miami Art Museum’s new complex, which will anchor the city’s 29-acre Museum Park, overlooking Biscayne Bay. At 120,000 sf with 32,000 sf of gallery space, the three-story museum will be three times larger than the current facility.

| Aug 11, 2010

Courtyard connects new and remodeled schools

Good Fulton & Farrell Architects of Dallas designed a major expansion and renovation at the Dallas Academy in Texas. The 22,900-sf addition serves as the school’s new front door and includes a library, student assembly area, cafeteria, seven classrooms, and administrative offices. The school’s existing 14,560-sf building was renovated to accommodate a lower school component, and...