With a new project on the horizon for Canada’s largest telecom, local structural engineering firm, Glotman-Simpson had an idea: The use of long-span composite steel decking could be ideal for such a large-scale project, contributing to an open, column-free design. So, they brought the idea to the attention of the architecture firm, Henriquez Partners.

Soon, a number of structural challenges became clear.

An open floor plan, controlled acoustics and floor vibration were significant obstacles. Another consideration was to maximize floor-to-ceiling height, while accounting for mechanical and electrical distribution. To address these concerns, New Millennium Building Systems was called upon to coordinate with the architect and engineer. Together, they arrived at a Deep-Dek® composite 6.0 steel deck profile to address all concerns.

The open floor plan and towering open spaces of the Telus Garden office project feature Deep-Dek® composite steel deck slab construction. Floor-to-ceiling heights were maximized by MEP integration and the elimination of drop ceiling costs.

Built-in advantages of composite deck

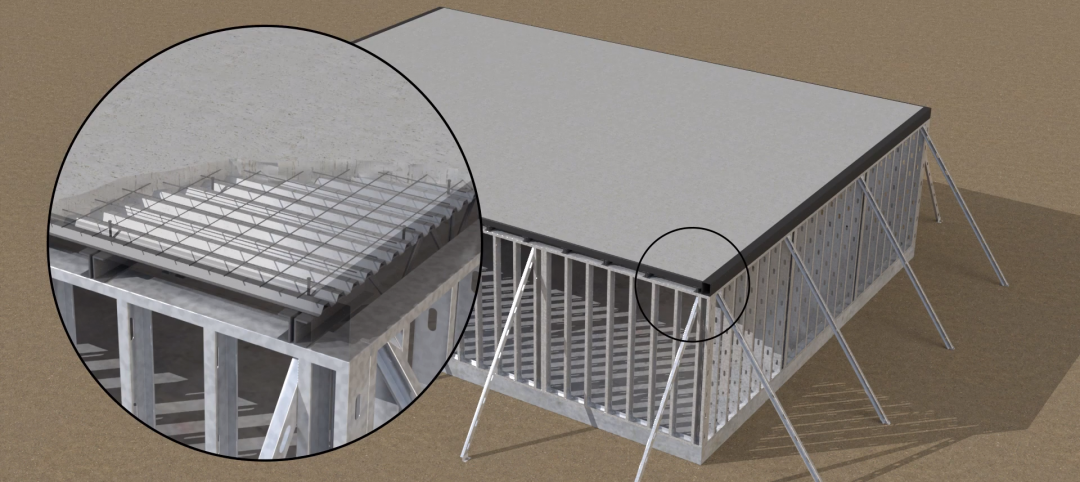

An important feature of the decking is the factory-produced closed ends of each deck section. The end closures enable the concrete to be poured continuously, as the tapered ends terminate at the supporting structure and increase its capacity to withstand large reactions at the bearing point. The steel decking integrates with the concrete for a UL-rated assembly. By adding a 5-inch normal weight concrete topping, the resulting 11-1/8-inch total slab depth has an unprotected 2-hour fire rating. Intumescent paint is required at the structural members only.

The factory closed ends of the Deep-Dek® allow for concrete to be poured continuously, increasing its capacity to withstand large reactions at the bearing point.

Vibration analysis

To meet the challenge of the open floor plan, the deck slab assembly cleared a remarkable span of 32-feet and is 30 to 35 percent lighter than an equal thin plate concrete slab. New Millennium provided vibration analysis and certified slab analysis that, unlike other composite designs, accounts for long-term deflection. While a cellular acoustical version of the composite deck is available, this was not pursued by the architect and engineering team.

During production, New Millennium pre-cut holes in the deck to accommodate junction boxes for electrical distribution. Mechanical piping and most ducts were run through the flutes of the deep deck profile. This maximized floor-to-ceiling heights, as typical high-rise construction can compromise ceiling heights by as much as five feet using dropped ceilings to conceal massive ducts. Also avoided were the costs for drop ceiling interstitial beams, material and labor.

For more information, please visit: www.newmill.com

Related Stories

Sponsored | BD+C University Course | May 10, 2022

Designing smarter places of learning

This course explains the how structural steel building systems are suited to construction of education facilities.

Sponsored | BD+C University Course | Apr 19, 2022

Multi-story building systems and selection criteria

This course outlines the attributes, functions, benefits, limits, and acoustic qualities of composite deck slabs. It reviews the three primary types of composite systems that represent the full range of long-span composite floor systems and examines the criteria for their selection, design, and engineering.

Contractors | Mar 28, 2022

Amid supply chain woes, building teams employ extreme procurement measures

Project teams are looking to eliminate much of the guesswork around product availability and price inflation by employing early bulk-purchasing measures for entire building projects.

Sponsored | BD+C University Course | Jan 30, 2022

Optimized steel deck design

This course provides an overview of structural steel deck design and the ways to improve building performance and to reduce total-project costs.

Sponsored | Steel Buildings | Jan 25, 2022

Structural Game Changer: Winning solution for curved-wall gymnasium design

Sponsored | Steel Buildings | Jan 25, 2022

Multifamily + Hospitality: Benefits of building in long-span composite floor systems

Long-span composite floor systems provide unique advantages in the construction of multi-family and hospitality facilities. This introductory course explains what composite deck is, how it works, what typical composite deck profiles look like and provides guidelines for using composite floor systems. This is a nano unit course.

Sponsored | BD+C University Course | Jan 12, 2022

Total steel project performance

This instructor-led video course discusses actual project scenarios where collaborative steel joist and deck design have reduced total-project costs. In an era when incomplete structural drawings are a growing concern for our industry, the course reveals hidden costs and risks that can be avoided.

Sponsored | BD+C University Course | Oct 15, 2021

7 game-changing trends in structural engineering

Here are seven key areas where innovation in structural engineering is driving evolution.