All kinds of recycled waste goes into public roads these days, including blast furnace slag, scrap tires, and roofing shingles, according to the Federal Highway Administration.

An estimated 300,000 metric tons of recycled plastic are also used annually as a binder additive for public roads in the U.S. But that’s a drop in the bucket compared to the five trillion pieces of plastic junk currently floating in the oceans, to which eight million metric tons of plastic waste gets added every year.

The Netherlands is trying to take this recycling to another level, and is vying to become the first country to pave streets with materials made entirely from plastic waste.

Dutch-based KWS Infra, the roads division of VolkerWessel, is piloting a program to make roads from plastic garbage, including bags and bottles extracted from the ocean, according to Fast Company. This PlasticRoad project, which is still on the drawing board, is part of a larger initiative to rid the seas of its “plastic soup”.

Alex van de Wall, KWS’s innovation manager, says that the plastic being used would include a waste stream that normally doesn’t have high-end recycling applications and would otherwise be burned.

KWS sees a number of advantages to using plastic trash for roads over asphalt or concrete:

• Recycled plastic has a considerable lower carbon footprint than the production of asphalt, which accounts for 2% of global carbon emissions. Plastics can also withstand greater extremes of temperature—between -40 Celsius and 80C.

• Plastic roads could be modularized—i.e., made in factories and then snapped together in the field—so a road could be built quicker than with asphalt. KWS also claims that plastic-made roads would be far more durable and easier to maintain and repair than asphalt roads.

• Plastic could be colored white, which would help keep cities cooler and reduce what van de Wall says is the “heat island” effect caused by asphalt paving. Once this concept is translated into an actual product, “There are many options,” he says.

• When a plastic road wears out, it could be recycled again.

KWS thinks it can overcome some of the problems related to using plastic for roads, such as how the product reacts to changing temperatures and gets very hot. The company plans to test plastic roads in the lab first and then try them out at a “street lab” in Rotterdam.

“We’re very positive towards the developments around PlasticRoad,” said Jaap Peters, from that city council’s engineering department. “Rotterdam is a city that is open to experiments and innovative adaptations in practice.”

KWS is currently looking for plastic supply partners to assess the financial feasibility of its design. And if this concept pans out, the company expects to export the idea to other countries.

Related Stories

Green | Jul 26, 2018

St. Paul aims for zero carbon in all buildings by 2050

The city is working for better efficiency and sourcing green power to reach its goal.

Green | Jul 26, 2018

DOE releases updated version of Better Buildings Financing Navigator

Version 2.0 provides renewable energy financing options, sector-specific and location-specific financing resources, and a smart database of financing providers.

Green | Jul 24, 2018

Cincinnati’s green approach to sewer discharge expected to save $100 million

Environmentally strategy does have its limits, though.

Codes and Standards | Jul 17, 2018

NIMBYism, generational divide threaten plan for net-zero village in St. Paul, Minn.

The ambitious redevelopment proposal for a former Ford automotive plant creates tension.

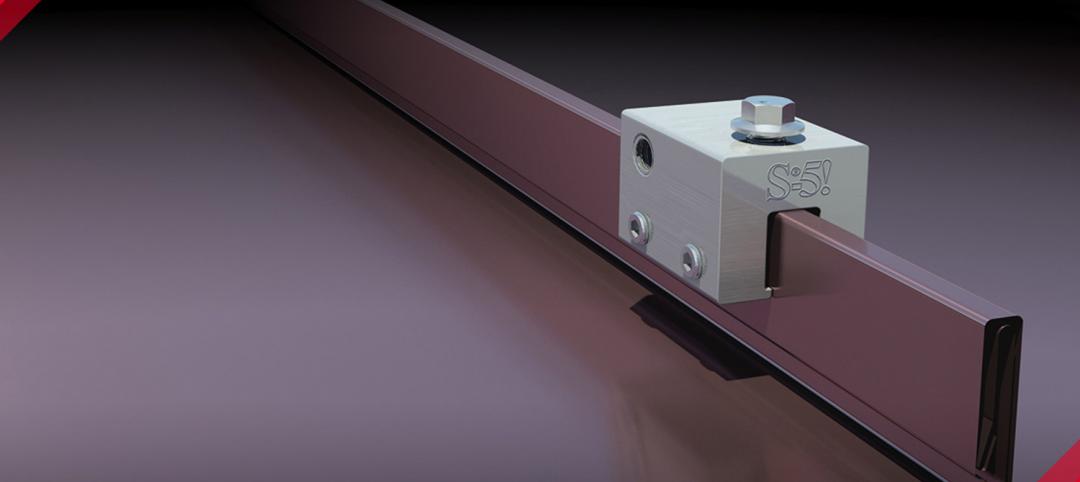

Sponsored | Energy Efficiency | Jul 2, 2018

Going solar has never been easier

There is an efficient system for mounting solar panels to roofs and turning roof real estate into raw power.

Multifamily Housing | Jun 27, 2018

To take on climate change, go passive

If you haven’t looked seriously at “passive house” design and construction, you should.

Accelerate Live! | Jun 24, 2018

Watch all 19 Accelerate Live! talks on demand

BD+C’s second annual Accelerate Live! AEC innovation conference (May 10, 2018, Chicago) featured talks on AI for construction scheduling, regenerative design, the micro-buildings movement, post-occupancy evaluation, predictive visual data analytics, digital fabrication, and more. Take in all 19 talks on demand.

Office Buildings | Jun 15, 2018

Portland’s newest office buildings put nature on center stage

Hacker Architects designed the space for Portland’s Frontside District.

| Jun 11, 2018

Accelerate Live! talk: Regenerative design — When sustainability is not enough

In this 15-minute talk at BD+C’s Accelerate Live! conference (May 10, 2018, Chicago), HMC’s Eric Carbonnier poses the question: What if buildings could actually rejuvenate ecosystems?

| May 30, 2018

Accelerate Live! talk: T3 mass timber office buildings

In this 15-minute talk at BD+C’s Accelerate Live! conference (May 10, 2018, Chicago), architect and mass timber design expert Steve Cavanaugh tells the story behind the nation’s newest—and largest—mass timber building: T3 in Minneapolis.