Prefabricated modular design and construction have made notable inroads into such sectors as industrial, residential, hospitality and, more recently, office and healthcare. But Dafna Kaplan thinks that what’s held back the modular building industry from even greater market penetration has been suppliers’ insistence that they do everything: design, manufacture, logistics, land prep, assembly, even onsite construction. “That’s been their Achilles’ Heel.”

Kaplan is CEO and Founder of Cassette, a Los Angeles-based startup that designs and sells stackable apartment-living pods with move-in-ready 80-sf kitchens, 60-sf bathrooms, 130-sf bedrooms with double wardrobe, and 162-sf living rooms. Last October, Cassette unveiled its 600-sf, one-bedroom model unit designed by Craig Hodgetts and Ming Fung of HplusF Design Lab in Culver City, Calif., at a popup showroom open for tours.

Cassette started in 2019, but was stalled for a while by Covid-19 restrictions. During that lull, Kaplan—who previously worked in an advisory capacity with ConXTech and MATT Construction—did a lot of consulting. The Covid period also saw some high-profile modular manufacturers stumble and fall, which gave Kaplan insight into what did and didn’t work. During the year before Cassette introduced its product, Kaplan also benefited from conversations with industry leaders like RAD Urban’s Co-founder Randy Miller and FullStack Modular’s CEO Roger Krulak.

Her main takeaway from all this: “We learned not to do too much.”

Savings from modular construction come from process improvements

Proponents have long touted modular as an answer to helping lessen America’s chronic housing shortage and rising construction costs, and Kaplan is no different. Cassette’s “mission” is to reduce the cost of multifamily housing construction by 30% in three years, and double the speed of housing production. By focusing half of the building design toward a fixed product/fixed price model, Cassette would bring more predictability to construction.

“The trick to reducing construction costs is to get the entire system to function in unison,” Kaplan tells BD+C. The cost savings will come, over time, from process improvements “and getting better with every iteration.”

Hodgetts of HPlusF Design Lab, who holds two modular patents, adds that great design “doesn’t have to be expensive,” and asserts that Cassette’s formula of developing a product through a lens of manufacturing and prefab will “make modular construction a practical reality.” (The designers and Nick Butcher, Cassette's COO, knew each other previously and had worked together before. “It was a mind meld of mutual respect,” says Kaplan.)

Modular building units in production in 2023

Kaplan says that what separates Cassette from its competitors starts with price transparency. Modular suppliers are often circumspect about comparing their prices with conventional design and construction. Cassette states its pricing upfront, and while it doesn’t require minimum orders, discounts are available when customers buy more, ranging from $170,000 per unit for orders under 15 units, to $140,000 with orders of 101 to 300 units, with incremental price reductions in between.

Pricing covers predevelopment design team coordination, interior design, floor-to-ceiling window/sliding door systems, 100% preinstalled waterproofing, major appliances, tankless water heater, all fixtures and finishes, a split HVAC system evaporator coil, and onsite delivery, installation, and structural hookup.

When interviewed in November, Kaplan said her company was “in discussions” with a half-dozen general contractors. Cassette also has manufacturing contracts with factories in Malaysia and South Korea, and was in discussions with a factory in Mexico. (Kaplan notes that the supply chain, and not the logistics, is the most critical part of the modular business.) From order to delivery will take about six months, she estimates.

The 14.5x43-foot product is sized so that “you don’t need a police car on the road to transport it,” says Kaplan. The pods are stackable up to six stories and include bracket support for attaching balconies and corridors. (Sitework includes elevators and stairs, and there are extra costs for roof slope and membrane, foundations, public circulation areas, and additional exterior façade.)

Late last year, Cassette was taking orders, and Kaplan fully expects to be building projects in 2023. She didn’t reveal much, except to say that one project in Los Angeles County will be 30 units, and another 200. Cassette eventually plans to expand its assortment to include studio and two-bedroom pods. Kaplan is also keeping an eye on renter demographics to gauge future demand for different apartment sizes and features. “It’s all about good architecture and design,” she says.

Related Stories

| Nov 25, 2013

Building Teams need to help owners avoid 'operational stray'

"Operational stray" occurs when a building’s MEP systems don’t work the way they should. Even the most well-designed and constructed building can stray from perfection—and that can cost the owner a ton in unnecessary utility costs. But help is on the way.

| Nov 19, 2013

Top 10 green building products for 2014

Assa Abloy's power-over-ethernet access-control locks and Schüco's retrofit façade system are among the products to make BuildingGreen Inc.'s annual Top-10 Green Building Products list.

| Nov 15, 2013

Greenbuild 2013 Report - BD+C Exclusive

The BD+C editorial team brings you this special report on the latest green building trends across nine key market sectors.

| Nov 15, 2013

Metal makes its mark on interior spaces

Beyond its long-standing role as a preferred material for a building’s structure and roof, metal is making its mark on interior spaces as well.

| Nov 13, 2013

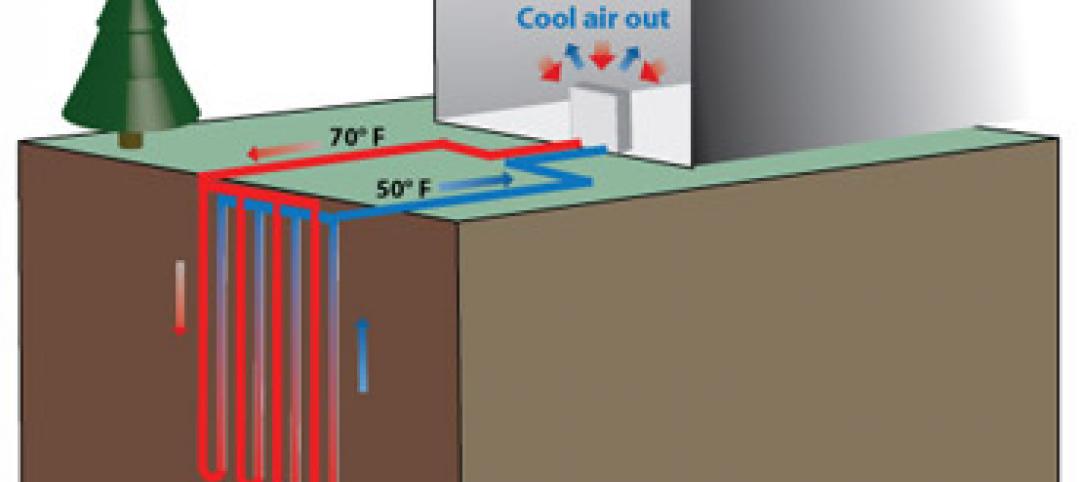

Installed capacity of geothermal heat pumps to grow by 150% by 2020, says study

The worldwide installed capacity of GHP systems will reach 127.4 gigawatts-thermal over the next seven years, growth of nearly 150%, according to a recent report from Navigant Research.

| Nov 8, 2013

Net-zero bellwether demonstrates extreme green, multifamily style

The 10-unit zHome in Issaquah Highlands, Wash., is the nation’s first net-zero multifamily project, as certified this year by the International Living Future Institute.

| Nov 6, 2013

Dallas’s goal of carbon neutrality by 2030 advances with second phase of green codes

Dallas stands out as one of the few large cities that is enforcing a green building code, with the city aiming to be carbon neutral by 2030.

| Oct 30, 2013

15 stellar historic preservation, adaptive reuse, and renovation projects

The winners of the 2013 Reconstruction Awards showcase the best work of distinguished Building Teams, encompassing historic preservation, adaptive reuse, and renovations and additions.

| Oct 30, 2013

11 hot BIM/VDC topics for 2013

If you like to geek out on building information modeling and virtual design and construction, you should enjoy this overview of the top BIM/VDC topics.

| Oct 28, 2013

Urban growth doesn’t have to destroy nature—it can work with it

Our collective desire to live in cities has never been stronger. According to the World Health Organization, 60% of the world’s population will live in a city by 2030. As urban populations swell, what people demand from their cities is evolving.