Tight space and time constraints are common for multifamily projects in high-density urban areas. To combat these challenges, Philadelphia-based VBC has made a name for itself by offering a modular solution. While designing Next LVL, a multifamily residence in the heart of the city, the VBC team discovered that MagicPak All-In-One™ HVAC Systems could help achieve each of the project’s major objectives, including more living space, faster occupancy and highly desirable rooftop gathering spaces.

Compared to traditional methods, using MagicPak® helped shave off two months of labor, while meeting the architect’s aesthetic vision for the building exterior. By eliminating outdoor equipment, Next LVL could offer more of the in-demand features that help attract and retain tenants, including an expansive rooftop lounge with greenspace and unobstructed views of the city.

Optimized Space and Amenities

With space at a premium, VBC wanted to fit as many units as possible into the building footprint. MagicPak eliminated the need to run vertical line sets throughout the building, meaning square footage traditionally needed for chaseways could be used for hallways or living units. It also simplified the overall design process.

“We don’t have to worry about line sets running into fire sprinkler lines and all of the other things that we have running through a complex system,” said Sara-Ann Logan, vice president of design at VBC.

Using the MagicPak system also had another major benefit: keeping 280 condensing units off the roof.

“When you’re in a city environment and every inch counts, you really don’t want to waste space by putting condensers in places that could otherwise be livable space or provide some sort of amenity to the tenants,” said Logan.

With no HVAC equipment on the roof, that space was now available for highly desirable (and potentially rent-boosting) amenities.

“In the city with very dense living, you always want to make sure that your tenants have the ability to connect to the outside,” Logan noted. “By choosing MagicPak, we unlocked the ability to use the space on the top floor and gave the tenants of this building a unique space that I think is one of the best in the city.”

As the project’s architect, Logan also pointed to the design flexibility afforded by MagicPak.

“I can align louvers with windows and really have the ability to design exterior features the way that I want to as an architect and the way honestly that the cities want us to,” said Logan. Working with MagicPak also allowed her to achieve the seamless aesthetic she was looking for by matching various exterior colors.

“In this particular project we have five to six exterior skin conditions,” said Logan. “Being able to match those and have those disappear with the exterior was critical, and it was really easy to do with the MagicPak system.”

Less Onsite Labor, Easier Maintenance

As a modular builder, VBC was already doing the bulk of its construction in the factory. With MagicPak, most of the HVAC work could also be done offsite under controlled conditions.

“It's a really unique system and it's very user-friendly for installation purposes,” said Robert Schmalbach, VBC vice president of construction.

The all-in-one units, duct work and thermostat were installed into each living unit in the factory, dramatically reducing the time needed for HVAC field teams onsite.

“When it comes to the site, all we need to do is commission that unit, turn it on and it works,” said Schmalbach. “By working with MagicPak on this project, we were able to basically limit the HVAC field teams, onsite component to roughly 30 days versus potentially 90 days if we had gone with a different type of system.”

The time-saving benefits extend beyond construction, making ongoing maintenance simpler and more convenient.

According to Schmalbach, MagicPak “extremely quiet and user-friendly.” And because it’s housed within an individual living unit, it’s protected from the elements and easy to service.

“The technician can simply go into that unit, observe what's going on and be able to fix it without having to either chase down a leak or go to multiple different areas, which potentially could have multiple different problems. For the developer, this really simplifies their systems and their warranty work and what they need to be prepared for.”

“With MagicPak, everything’s in front of me, I can easily access it all. And if worst case, if I have to pull the whole unit out, it’s doable in a safe environment.”

--

Contact Information

Phone: 1-800-448-5872

Email: MagicPakMarketing@alliedair.com

Website: www.magicpak.com

Related Stories

| Nov 14, 2014

What college students want in their living spaces

In a recent workshop with 62 college students, architects from Little explored the changing habits and preferences of today's students, and how those changes affect their living spaces.

| Nov 11, 2014

Renzo Piano's third building at London Bridge Quarter approved, will be built adjacent to the Shard

Renzo Piano Building Workshop has been granted planning approval for its residential building at London Bridge Quarter—a 26-story apartment tower dubbed Feilden House.

| Nov 7, 2014

Arts college uses creative financing to build 493-bed student housing

Many states have cut back funding for higher education in recent years, and securing money for new housing has been tougher than ever for many colleges and universities. A recent residence hall project in Boston involving three colleges provides an inspiring example of how necessity can spawn invention in financing strategies.

| Nov 7, 2014

Prefab helps Valparaiso student residence project meet an ambitious deadline

Few colleges or universities have embraced prefabrication more wholeheartedly than Valparaiso (Ind.) University. The Lutheran-based institution completed a $27 million residence hall this past summer in which the structural elements were all precast.

| Nov 3, 2014

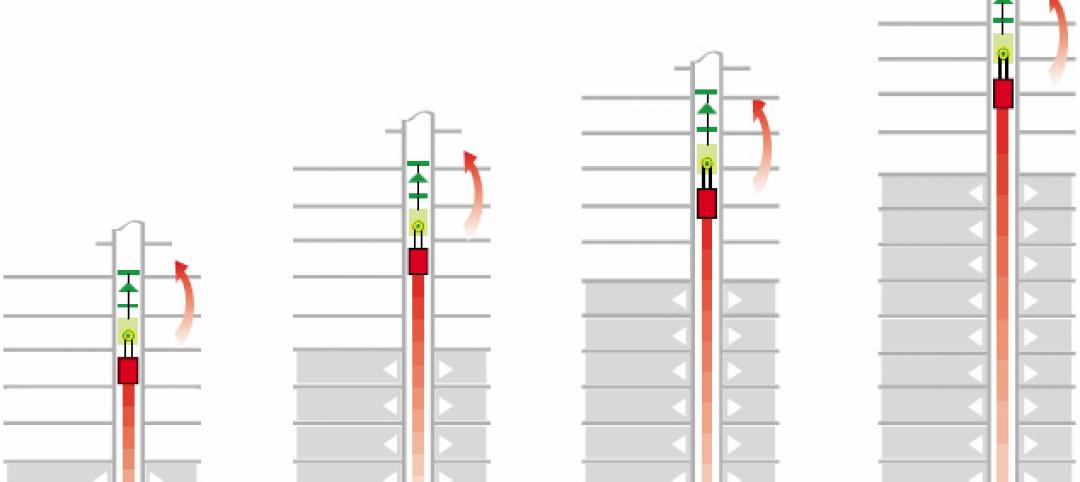

Novel 'self-climbing' elevator operates during construction of high-rise buildings

The JumpLift system from KONE uses a mobile machine room that moves upward as the construction progresses, speeding construction of tall towers.

| Nov 3, 2014

Cairo's ultra-green mixed-use development will be topped with flowing solar canopy

The solar canopy will shade green rooftop terraces and sky villas atop the nine-story structure.

| Oct 31, 2014

Dubai plans world’s next tallest towers

Emaar Properties has unveiled plans for a new project containing two towers that will top the charts in height, making them the world’s tallest towers once completed.

| Oct 29, 2014

Better guidance for appraising green buildings is steadily emerging

The Appraisal Foundation is striving to improve appraisers’ understanding of green valuation.

| Oct 27, 2014

Studio Gang Architects designs residential tower with exoskeleton-like exterior for Miami

Jeanne Gang's design reinvents the Florida room with shaded, asymmetrical balconies.

| Oct 21, 2014

Passive House concept gains momentum in apartment design

Passive House, an ultra-efficient building standard that originated in Germany, has been used for single-family homes since its inception in 1990. Only recently has the concept made its way into the U.S. commercial buildings market.