According to Christine Williamson, a building scientist and consultant who built her career studying building failures, a single building mistake or installation error in new construction can lead to compounding problems, while a single wise decision, well executed, can lead to disproportionate benefits in building performance.1

While building performance in multi-family construction sometimes refers to acoustic performance, other factors such as fire protection are equally important.

To successfully build with these considerations in mind, architects and developers must keep pace with guidelines from code bodies while turning to innovative product solutions to get the job done effectively.

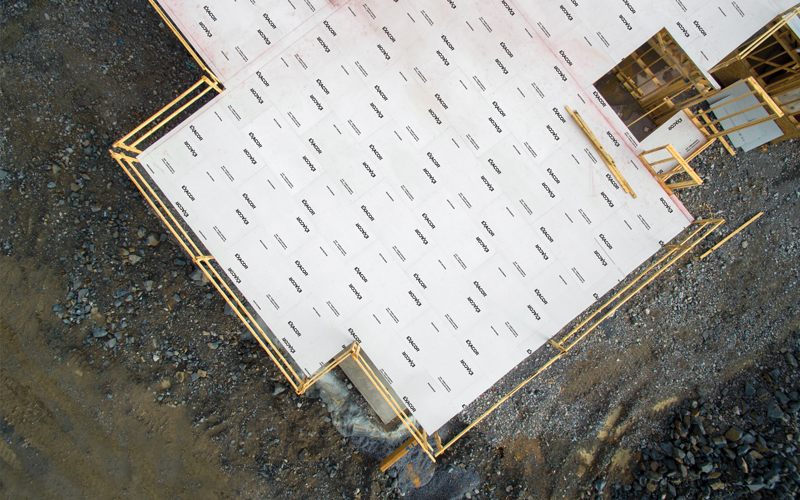

TDK Construction, a development and construction company in Murfreesboro, Tennessee, is doing just that with the recent use of EXACOR™ magnesium oxide (MgO) panels, a decision its team agrees equated to real time savings in a recent 127-unit luxury apartment community in Goodlettsville, Tennessee.

Time is money

Historically, wet-laid gypsum underlayment and a sound mat have been the go-to materials for fire resistance and sound attenuation in floor assemblies of multifamily construction.

The biggest issue with gypsum underlayment has always been the additional time the installation and curing process can add to a construction schedule.

Due to the constraints of skilled labor, builders have to schedule gypsum underlayment sub-contractors well in advance, the application cure time adds weeks to the timeline, and many take issue with the large amount of moisture the liquid-based product adds to the job.

So, when there are time and budget savings to be had with new building technologies, multifamily builders such as TDK Construction are open to change.

“Our construction supply company sales rep had other contractors in the area say they were skeptical, but as we were laying EXACOR™ underlayment down, they saw how quick [the process] was. It was faster than laying just traditional subfloor,” said Todd Hardy, supervisor for TDK Construction. “Time is money and if we can save time on one job, let alone all our jobs, that really adds up.”

According to Hardy, the EXACOR underlayment installation took less time than installing gypsum underlayment and eliminated the need for an additional crew to be added to the schedule.

Hardy’s framing crew worked quickly and were already on site to install the EXACOR underlayment over the subfloor they had just completed. He estimates that using EXACOR underlayment saved the company approximately $30,000 in their budget and knocked almost two months off the construction schedule2, allowing potential renters of the luxury apartment complex to start moving in sooner than originally projected.

Meeting fire and sound rating requirements

Time and money savings aside, EXACOR MgO panels can also succinctly address two of the biggest concerns in multifamily dwellings: fire resistance and sound attenuation.

When used in specific fire and sound rated assemblies, EXACOR underlayment panels can meet the fire rating,3 sound rating3 and dimensional stability requirements of most multifamily and light commercial job sites.

EXACOR panels are also fire resistant3 due to a magnesium oxide formula and provide strength and stability due to the integrated mesh core for structure.4

“The fire marshal’s main concern is always meeting the UL rating — it needs to maintain a one-hour fire-rated floor assembly,” Hardy said. “When we put the subfloor in and then the EXACOR underlayment, the UL rating was achieved.”4

Next is the issue of sound attenuation. While some background noise in multifamily living is common, excessive noise can lead to high tenant turnover.

Developers and architects must design to minimum thresholds for airborne sound transfer set by the International Building Code (IBC) to meet certain Sound Transmission Class (STC) ratings. Additionally, the IBC determines structure borne transfer ratings for Impact Insulation Class (IIC), or how a floor/ceiling assembly transmits the sound of an impact.

In layman's terms, STC ratings cover airborne noises like talking, music or appliances in neighboring apartments, and IIC ratings include impact noises like footfall, dropped items and furniture movement.

“With construction projects like ours — a three-story building — you want to make sure you alleviate all the sound from above, and that is always one of the architect’s biggest challenges,” Hardy said. “With the gypsum underlayment assembly we’ve used in the past, we had to add a sound mat between the gypsum underlayment and the finished flooring. This was eliminated with the EXACOR underlayment assembly.”

EXACOR panels also provide added sound attenuation benefits. When used as a part of a STC/IIC-tested floor/ceiling assembly, EXACOR underlayment panels installed over plywood or OSB subfloors can help builders achieve or exceed code minimums for dwelling separations.

EXACOR underlayment assemblies also may eliminate the need for a sound mat, depending on the architect’s overall flooring assembly design.

An immediate difference

Fire and sound codes satisfied, it was the time savings of using EXACOR MgO panels that resonated most with Hardy and builder/owner TDK Construction. Unlike gypsum underlayment, which is poured after exterior and interior walls are in place, EXACOR panels can be installed by framers as part of the framing package, with walls then framed on top of the EXACOR panels. That means one crew can install both the underlayment and framing, using their existing tools, equating to time and budget savings.

Hardy also noticed that eliminating gypsum underlayment meant they did not have to make any adjustments to [door headers] on the second or third floors since there wasn’t any variance in the thickness of EXACOR underlayment.

“Our framers could prefab everything, they don’t have to worry about the first, second, third floor being different,” Hardy said. “With gypsum underlayment, there were always unknowns, things you wouldn’t discover until you’re deep into the construction process.”

An added bonus for crews? No mess. EXACOR can eliminate cleaning headaches associated with gypsum underlayment, such as spills, difficulty around tub framing, threshold unevenness and more.

“Not to mention the mess that the wet-laid gypsum crew can make — it gets everywhere - on the walls, on the tubs, all over the place - and we spend a lot of time just cleaning it up,” Hardy said.

Going forward

As multifamily construction continues to evolve, products that upgrade and innovate the process will be needed. Using innovative solutions such as EXACOR MgO panels is one way to address those needs, accelerating the ease of the construction process and providing a glimpse of what better building looks like.

TDK Construction will be one of those better builders leading the way in multifamily dwellings made with EXACOR MgO panels.

“We’ll use this for everything going forward. At TDK Construction, everything we build, we own. Our owner and developer are all about getting it done, and they were super happy with the results,” Hardy said.

Learn more about EXACOR™ products.

- Williamson, Christine. “Acoustic Control in Multi-Family Construction.” Home Building Crossroads, Feb. 2021, www.huberwood.com/events/home-building-crossroads/archive/acoustic-control-in-multi-family- construction.

- Pricing will vary by region, check with your local channel partner on pricing and availability.

- EXACOR panels may be used in specific published fire-resistant-rated assemblies as tested in accordance with ASTM E119 / ANSI UL 263. Follow published fire-resistance rated assembly requirements and consult local building codes and designer of record for fire-resistant design requirements.

- This job was designed in accordance with UL L528. Click here to see the assembly specifications. Sound and fire ratings vary by assembly. Refer to the EXACOR Sound & Fire Assemblies Handbook available at exacor.com/acoustics.

Exacor.com

800.933.9220

techquestions@Huber.com

Related Stories

Multifamily Housing | Jan 31, 2015

Production builders are still shying away from rental housing

Toll Brothers, Lennar, and Trumark are among a small group of production builders to engage in construction for rental customers.

Multifamily Housing | Jan 29, 2015

5 predictions for the multifamily sector in 2015

Brian Carlock of PwC expects more younger adults to get into the game, despite continuing affordability issues.

Multifamily Housing | Jan 27, 2015

Multifamily construction, focused on rentals, expected to slow in the coming years

New-home purchases, which recovered strongly in 2014, indicate that homeownership might finally be making a comeback.

Multifamily Housing | Jan 22, 2015

Sales of apartment buildings hit record high in 2014

Investors bet big time on demand for rental properties over homeownership in 2014, when sales of apartment buildings hit a record $110.1 billion, or nearly 15% higher than the previous year.

Modular Building | Jan 21, 2015

Chinese company 3D prints six-story multifamily building

The building components were prefabricated piece by piece using a printer that is 7 meters tall, 10 meters wide, and 40 meters long.

| Jan 19, 2015

Four Seasons tower will be Boston's tallest

On Jan. 14, 2015, developer Carpenter & Company and executives from the Four Seasons broke ground on the Four Seasons Hotel & Private Residences, which will become the tallest building in Boston at 699 feet.

Smart Buildings | Jan 7, 2015

Best practices for urban infill development: Embrace the region's character, master the pedestrian experience

If an urban building isn’t grounded in the local region’s character, it will end up feeling generic and out-of-place. To do urban infill the right way, it’s essential to slow down and pay proper attention to the context of an urban environment, writes GS&P's Joe Bucher.

| Jan 6, 2015

Construction permits exceeded $2 billion in Minneapolis in 2014

Two major projects—a new stadium for the Minnesota Vikings NFL team and the city’s Downtown East redevelopment—accounted for about half of the total worth of the permits issued.

| Jan 2, 2015

Construction put in place enjoyed healthy gains in 2014

Construction consultant FMI foresees—with some caveats—continuing growth in the office, lodging, and manufacturing sectors. But funding uncertainties raise red flags in education and healthcare.

Sponsored | | Dec 30, 2014

Case studies: Engineered wood brings cost savings, design flexibility across commercial project types

For commercial architects facing increasing pressure to design innovative structures while simultaneously cutting costs and accommodating tight deadlines, engineered wood systems are providing a welcome solution.