On March 20, Meritus Health Center in Hagerstown, Md., submitted an emergency certificate of need to the state of Maryland’s Healthcare Commission, which one day later approved the hospital’s plan for its permanent 2 South Regional Infection Containment Wing to support COVID-19 infected patients.

Two days after that approval, Gilbane Building Company and Matthei & Colin Associates started assembling a building team to design and build this new facility. (A decade earlier, this same team built the 510,000-sf, 267-bed Meritus Medical Center in what at that time was a record 30 months.)

“Eight days after our initial call, our team was moving soil and digging foundations,” says Gary Orton, vice president and director of healthcare for Gilbane’s Mid-Atlantic division. “A project like this would typically take more than a year to conceptualize, design and build, but we didn’t have that kind of time.”

The steel framing was erected in six weeks and the building was airtight in two months. Streamlining was evident in the reduction of the construction punch list to seven open items, from 73.

The 12,560-sf addition was completed on July 31; the time between the start of designing this wing and its receipt of a temporary certificate of occupancy was only 120 days. The addition was accepting patients by early August.

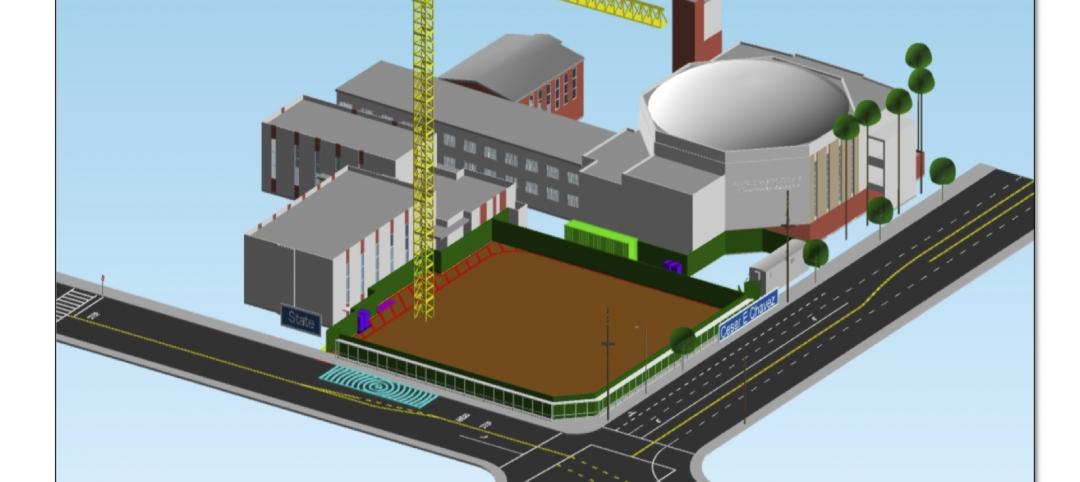

Also see: A time-lapse video of the hospital wing’s construction

A STREAMLINED PROCESS

As this project proceeded, the first critical steps, according to Matthei & Colin, were defined as: identifying long lead materials/systems and get them ordered as the building was being designed; engaging County and State officials to develop a plan to streamline the permit processes, while ensuring quality and safety of the final product; and developing a schedule with major milestones identified along the critical path.

“We reinvented decision making and certification processes to recognize the realities of working remotely and serving the schedule to bring the facility online as quickly as possible for the community,” says William Heun, lead architect for the project and partner with Matthei & Colin Associates.

According to Gilbane, the fast-track schedule was abetted by bringing the Washington County (Md.) permit and inspections department into daily meetings with the Building Team, to identify areas of improvement and to minimize delays in the permitting and life safety processes.

Gilbane adds that the design-to-permit time for the addition, which normally would take six to nine months for a building this size, was whittled down to less than six weeks.

The team exercised Lean practices to coordinate and streamline processes, expedite permitting, and procurement, design, and construction.

Exterior metal stud wall framing was fabricated on the ground and lifted into place when the structural steel frame was erected. Millwork and casework were assembled in the largest and most complete units possible. Headwalls were prefabricated with all power, gases, outlets and light controls in place, reducing installation time and providing a single point of connection above the ceiling. Door hardware was installed on doors off site, to minimize carpenters’ time in the project area.

Among the project's time-saving measures was prefabricating the patient room headwalls. Image: Gilbane, courtesy of Meritus Health.

ADDITION SUITED TO TREAT ALL INFECTIOUS DISEASES

CM Cost Plus Fee was the delivery method deployed for this $12.5 million addition, which is the first of its kind in the region, with 20 ventilator-capable negative pressure isolation rooms designed and built to contain any type of infectious disease. A sophisticated nurse call system enhances connectivity between patients and the nursing staff. Eight of the wing’s rooms have corridor windows with integrated blinds.

The Building Team included Frederick, Seibert & Associates (CE, land surveying, and landscape architecture), Leach Wallace Associates (MEP engineer), and GRAEF-USA (SE). Other suppliers and subcontractors listed are Heffron, Cindell Construction, Davenport Commercial, Ellsworth Electric, Emmitsburg Glass, Johnson Controls, Kalkreuth Roofing and Sheet Metal, KBK Builders, Kinsley Manufacturing, Modular Services, PAINTech, Ruppert Landscape, Robert W. Sheckles, Siemens, Swisslog Healthcare Solutions, Triad Engineering, and Virginia Sprinkler.

Related Stories

| Oct 24, 2012

Loma Linda University Medical Center lets light in with metal wall systems

Designers for the building aimed to create a positive environment for patients and visitors, and wanted to let in as much natural daylight as possible.

| Oct 11, 2012

Hank Adams Named to Lead HDR’s Healthcare Program

With more than 25 years of experience, HDR vice president is tapped to lead firm's healthcare projects.

| Oct 10, 2012

Skanska to Construct Children’s Hospital of Richmond at Virginia Commonwealth University Pavilion

Skanska USA announced that it has been awarded an $80 million contract to construct a new Children’s Pavilion at Children’s Hospital of Richmond at VCU.

| Oct 2, 2012

Bernards working on project at L.A. White Memorial Medical Center

The new facility is a $15-million, 41,000-sf concrete structure which includes three stories of medical office space atop a three-level parking garage.

| Sep 28, 2012

Seattle is home to first LEED-certified modular radiation center

By using modular construction and strategic site design, RAD Medical Systems built the first radiation center to receive LEED certification.

| Sep 20, 2012

Forrester begins construction of freestanding cancer center in Montgomery County, Md.

The new 51,000-square-foot building will include two linear accelerator vaults for radiation equipment.

| Sep 7, 2012

Healthcare architects get a preview of tomorrow’s medical landscape

The topic on everyone’s mind was how the Affordable Care Act would impact healthcare design and construction––and whether the law would even make it past the coming election cycle.

| Sep 7, 2012

Lucile Packard Children’s Hospital breaks ground on expansion

Sustainability and nature at the heart of the new addition at the Stanford University Medical Center designed by Perkins+Will.

| Sep 6, 2012

CPPI awarded $30.3 million contract for University of Florida’s Harrell Medical Education Building

The specialized interdisciplinary learning environment will serve as a focal point for integration and program development for all primary care educational activities in the College of Medicine.

| Aug 29, 2012

BOND completes South Cove Community Health Center

$11 million, 21,000 square foot community health center opens in Quincy, Mass.