Hy-Vee grocery has established itself as one of the top 25 grocery retailers in the country. The organization has built 240 stores throughout eight midwestern states and employs over 85,000 people. A common thread to the grocery chain’s expansion? Fabcon Precast.

DIFFERENT BUSINESSES. A COMMON APPROACH

As the go-to provider of precast concrete panels for many grocery chains throughout the country, Hy-Vee looks to Fabcon for expertise in both the production of precast panels and the build-out of its stores.

“The biggest thing for grocery – and retail clients in general – is speed of construction,” said Fabcon’s Matt Smith. “They want to get the registers up and running as quickly as possible. The fastest way to do that is with precast.” While speed is always vital, the grocer has grown to appreciate our service throughout the entirety of a project. And much like itself, also the way we’ve proven to help them keep costs in check.

CLIMATE CONSIDERATIONS, INSIDE & OUT

“Like many of the grocers we work with,” said Fabcon’s Don Johnson, “Hy-Vee gravitates to our 12” VersaCore+Green™ sandwich panels and their impressive R-value of 28.2.”

Featuring edge-to-edge insulation, these panels meet energy efficiency requirements and are effective at maintaining a comfortable shopping environment, regardless of climate. This helps to enhance the customer experience, but it also saves plenty of money in heating and cooling throughout the life of a store.

Not all grocery stores are created equal. And Hy-Vee is no exception. So if the in-store experience was so much better than its competitors, why look like everyone else? Fabcon has worked closely with Hy-Vee’s architects and designers to produce a custom finish for their precast panels. This helps the chain’s stores stand out from the pack. And create a positive impression of the brand the moment a customer approaches the store.

Experienced crews and better engineering insure that Fabcon walls go up fast making room for other subcontractors to get to work quicker.

Experienced crews and better engineering insure that Fabcon walls go up fast making room for other subcontractors to get to work quicker.

QUICK TO BUILD. QUICKER TO MARKET

“Because of the close working relationships, all parties at the table develop a kind of “short hand” when working with architects, general contractors and management from the grocery chains,” said Johnson. “’It’s just like the one we built in Cedar Rapids,’ for example, that only serves to speed up the process and eliminate pitfalls along the way.”

This means that from the plant to the install crews, many of our employees have direct experience with a Hy-Vee project. And it shows as subsequent builds go that much easier. With multiple production facilities, we’re able to produce the required panels to handle multiple projects at one time.

“On the larger end of things, there are always efficiencies when you repeat a design,” said Smith. “Even if the architect is designing buildings in several states, you’re not starting from scratch each time – both in terms of production and build-out.” This is how Hy-Vee moves so quickly from Ground Breaking to Grand Opening.

Then it’s off to the next store and another call to Fabcon Precast.

Related Stories

| Nov 3, 2011

GREC Architects announces opening of the Westin Abu Dhabi Golf Resort and Spa

The hotel was designed by GREC and an international team of consultants to enhance the offerings of the Abu Dhabi Golf Club without imposing upon the dramatic landscapes of the elite golf course.

| Nov 2, 2011

CRSI’s Manual of Standard Practice now available

This resource contains information on recommended industry practices for estimating, detailing, fabricating, and placing reinforcing steel for reinforced concrete construction.

| Nov 1, 2011

Holcim awards winners for North America announced

A socio-architectural project to create regional food-gathering nodes and a logistics network in Canada's high arctic territory won the top prize for North America of $100,000.

| Oct 14, 2011

ACI partners with CRSI to launch new adhesive anchor certification program

Adhesive anchor installer certification required in new ACI 318-11.

| Oct 12, 2011

FMI’s Construction Outlook: Third Quarter 2011 Report

Construction Market Forecast: The general economy is seeing mixed signs.

| Oct 12, 2011

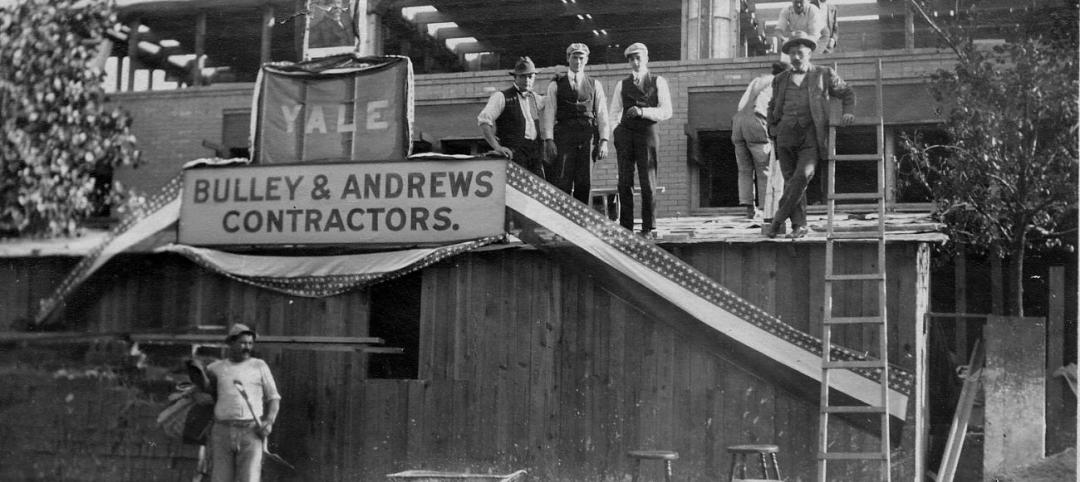

Bulley & Andrews celebrates 120 years of construction

The family-owned and operated general contractor attributes this significant milestone to the strong foundation built decades ago on honesty, integrity, and service in construction.

| Oct 7, 2011

GREENBUILD 2011: Transparent concrete makes its North American debut at Greenbuild

The panels allow interior lights to filter through, from inside.

| Oct 6, 2011

GREENBUILD 2011: Growing green building market supports 661,000 green jobs in the U.S.

Green jobs are already an important part of the construction labor workforce, and signs are that they will become industry standard.

| Oct 5, 2011

GREENBUILD 2011: Sustainable construction should stress durability as well as energy efficiency

There is now a call for making enhanced resilience of a building’s structure to natural and man-made disasters the first consideration of a green building.

| Oct 4, 2011

GREENBUILD 2011

Click here for the latest news and products from Greenbuild 2011, Oct. 4-7, in Toronto.