Located in Williamstown, Ky., the Ark Encounter, a 510-foot long wooden boat, is designed to be a family-oriented, historically authentic and environmentally friendly attraction. Created by Answers in Genesis (AiG), a Christian ministry, the Ark Encounter opens in July, 2016, and will bring to life the depictions of the historical events of Noah’s Ark.

The Ark Encounter, a $91.5 million project, is phase one of an entire religious theme park. Additional phases to be completed on the 800-acre site include a pre-flood city, a petting zoo and a walk-through aviary. The Creation Museum, an AiG museum located 40 miles from the Ark, was the first job Applied Mechanical Systems, the mechanical contractor for the Ark, did for AiG.

“They liked our work,” said Brian Hogue, plumbing foreman for Applied Mechanical Systems (AMS). “Our mechanical engineers went to Troyer Group, who is constructing the Ark Encounter, about four years ago and helped their engineering firm with code issues and three years later, when they were ready to start construction, they gave us the job.”

Troyer Group specified the use of Viega ProPress for copper for all the potable water lines, in sizes ranging from ½" to 4", and Viega MegaPressG for the natural gas lines, ranging from ½" to 2".

Ronald Troyer, Senior Vice President of Troyer Group, has included Viega products in various projects. He and Hogue emphasized that the flameless technology and ease of use were the motivating factors for specifying Viega.

Flameless install at largest timber-frame structure

Flameless install at largest timber-frame structure

“The no-heat and no-flame installation of plumbing piping was a definite plus,” said Troyer. “As with most projects of this scale, meeting a tight construction schedule was also a great fit for Viega products. The ease of installation which equated to cost savings with copper pipe was also a plus.”

Hogue agreed and expressed his appreciation for the overall quality of the Viega products and the difference it made on this project.

“Seeing how this is the largest timber frame wood structure in the world, they did not want open flame in the Ark,” Hogue said. “In my opinion, Viega MegaPress and Viega ProPress fittings are built well. There are a lot fewer leaks than other press manufacturers’ fittings. Plus, you save more time, making them cost effective.”

AMS has been installing Viega system solutions in applications where soldering would be prohibitive, and the time saved gives them the opportunity to stay ahead of the game on many jobs.

“It’s great for shut downs in factories where you don’t have time to worry about draining the system,” Hogue said. “In our Dayton offices, we use it a lot in hospitals, since it is a clean process of joining pipe. I highly recommend Viega systems.”

For more information, visit www.viega.us.

Related Stories

Sponsored | | Nov 5, 2014

How to maximize affordability and sustainability through all-wood podiums

Wood podium construction takes an age-old material and moves it into the 21st century.

Sponsored | | Oct 13, 2014

CLT, glulam deliver strength, low profile, and aesthetics for B.C. office building

When he set out to design his company’s new headquarters building on Lakeshore Road in scenic Kelowna, B.C., Tim McLennan of Faction Projects knew quickly that cross-laminated timber was an ideal material.

| Oct 13, 2014

Department of Agriculture launches Tall Wood Building Competition

The competition invites U.S. developers, institutions, organizations, and design teams willing to undertake an alternative solution approach to designing and building taller wood structures to submit entries for a prize of $2 million.

Sponsored | | Oct 7, 2014

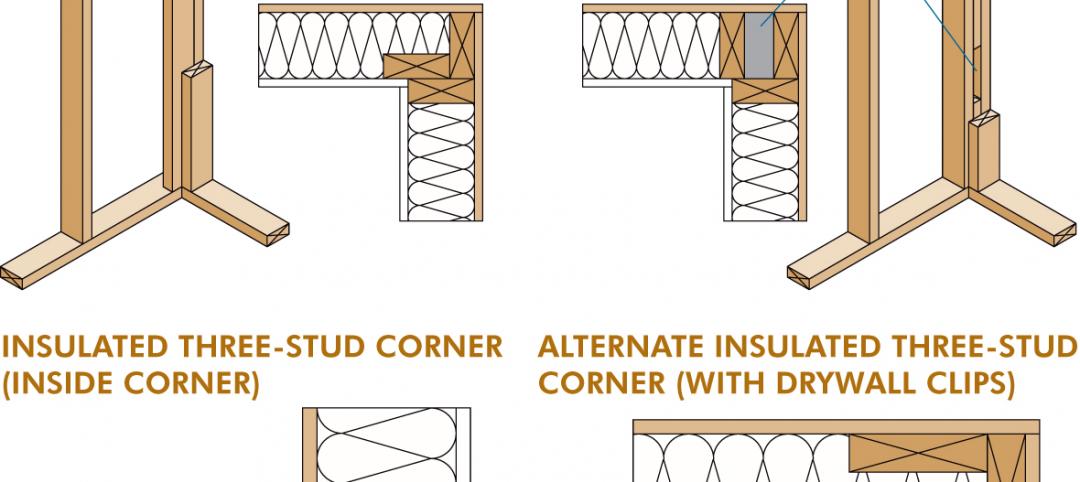

Boost efficiency with advanced framing

As architects continue to search for ways to improve building efficiencies, more and more are turning to advanced framing methods, particularly for multifamily and light commercial projects.

| Jul 24, 2014

MIT researchers explore how to make wood composite-like blocks of bamboo

The concept behind the research is to slice the stalk of bamboo grass into smaller pieces to bond together and form sturdy blocks, much like conventional wood composites.

| Jul 14, 2014

Meet the bamboo-tent hotel that can grow

Beijing-based design cooperative Penda designed a bamboo hotel that can easily expand vertically or horizontally.

| Jul 9, 2014

Demolition danger: Traditional Japanese architecture under threat in Tokyo district

Residents are trying to block developers from destroying historic architecture in Tokyo's Yanaka district, where a remarkable number of traditional buildings survived the Great Kanto Earthquake of 1923 and World War II.

| May 29, 2014

Wood advocacy groups release 'lessons learned' report on tall wood buildings

The wood-industry advocacy group reThink Wood has released "Summary Report: Survey of International Tall Wood Buildings," with informatino from 10 mid-rise projects in Europe, Australia, and Canada.

| May 28, 2014

Must see: Check out this one-of-a-kind lobby covered with 2,150 pieces of reclaimed wood

The recently opened NewActon Nishi apartment complex in Canberra, Australia, features one of the more unique lobby spaces you'll see, with thousands of pieces of repurposed timber suspended from the walls and ceiling.

| May 2, 2014

Norwegian modular project set to be world's tallest timber-frame apartment building [slideshow]

A 14-story luxury apartment block in central Bergen, Norway, will be the world's tallest timber-framed multifamily project, at 49 meters (160 feet).