A new survey of building owners and contractors highlights the challenges of managing construction projects when software applications lack automated data exchange processes.

The report, “Connecting Owners and Contractors: How Technology Drives Connected Construction,” was released by e-Builder, a Trimble Company, and Dodge Data & Analytics. It is based on responses to online surveys last Spring from 112 contracting companies and 98 building owners. Nearly three-quarters of the contractor respondents identify themselves as GCs. Sixty-nine percent of the owners operate within the public sector, and most focus on education, government, or healthcare projects.

Among these companies, 57% of owners and 52% of contractors say they use Project Management Information Systems (PMIS). However, these systems often are not compatible: only 16% of contractors say that an owner’s PMIS is the same as their own, and only 14% say they can integrate the two systems. But owners appear to have the upper hand here, as seven out of 10 owner-respondents with PMIS require contractors to use the owner’s system. More than half of these owners deploy their systems on more than half of their projects.

Consequently, about two-fifths of contractors say they end up using the owners’ systems and their own, leading to double data entry that, the survey found, has a negative impact on worker productivity, workflow, accuracy, decision making, and scheduling.

The survey finds that most owners insist that their PMIS prevail as the system used. That demand can present more work for contractors that also prefer to use their own systems.

More than one-third of contractors say they use the owner’s PMIS exclusively. The risk for contractors that use an owner’s PMIS, according to the survey, include increased costs, lack of proper documentation in the event of a claim, lack of project performance data and reports.

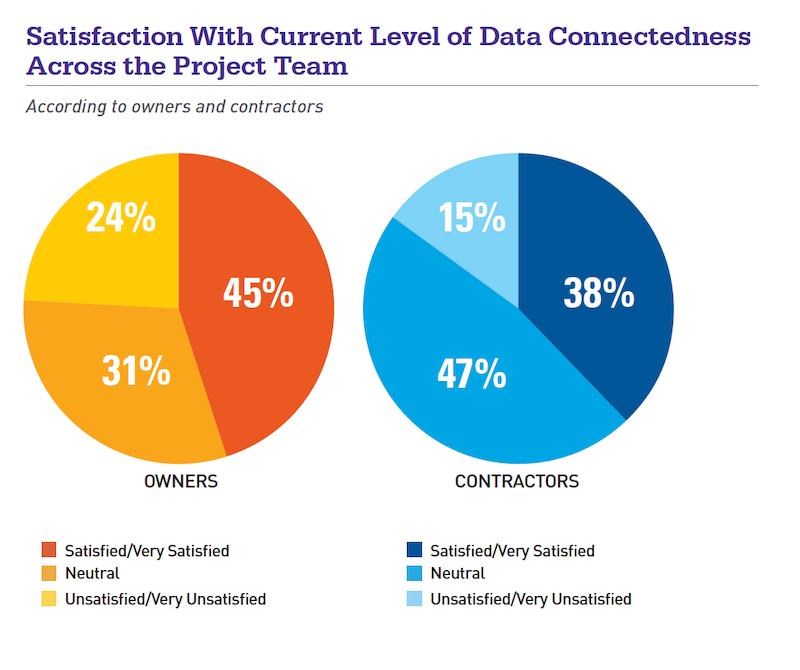

The disconnect, however, is that contractors see all these risks as being much bigger problems than owners do. Only two fifths of contractors are satisfied with the status quo, compared to nearly three fifths of owners. Contractors, though, also tend to be more neutral than owners about these systems’ incompatibilities, apparently accepting inefficiencies as part of doing business.

The irony is that there’s consensus among contractors and owners about, and a high level of satisfaction with, the overall benefits of using PMIS to handle such things as submittals and RFIs. Sixty-five percent of owners and 51% of contractors see high/very high value in a single platform that all parties use on projects for data management. “Both believe that creating a more seamless workflow for their processes would increase the value they receive,” the report states.

Contractors and owners agree that there's value in managing projects using a single, seamless system.

The report quotes Aaron Haas, Executive Vice President and construction manager with Howard Hughes, that within such a seamless scenario “there should be no miscommunication about cost, change orders, RFIs, submittals; it’s all one unified system.” Contractors in general believe that the key to accelerating this project process, and to getting paid quicker, is better data exchange.

But the industry has a ways to go to reach that plateau. The survey finds that 73% of contractors still use manual methods to measure project progress on more than half of their jobs, and 49% of pros subjectively estimate project progress on more than half of their jobs.

\More than a quarter of contractors don’t use a PMIS because they think it’s too expensive, and 23% think it’s too complicated. But 58% expressed a moderate to higher interest in using a system within the next three years.

Related Stories

| Dec 18, 2019

Reconsidering construction robotics

After decades when experts predicted that robots would become more prevalent on construction sites, it would appear that the industry has finally reached that point where necessity, aspiration, and investment are colliding.

Big Data | Dec 4, 2019

AEC data's coming out party

AEC firms are finally putting to use project information they’ve been storing in their computers for years.

AEC Tech | Oct 30, 2019

Robot masons work with humans on a $52 million housing project in Illinois

The machines address trade labor shortages, as well as worker wellbeing and safety.

AEC Tech | Oct 29, 2019

Bluebeam launches Revu 2019, with accelerated rendering and enhanced measurement functionality

The latest version of the company's flagship tool focuses on accuracy, speed, standardization.

3D Printing | Sep 17, 2019

Additive manufacturing goes mainstream in the industrial sector

More manufacturers now include this production process in their factories.

Multifamily Housing | Sep 12, 2019

Meet the masters of offsite construction

Prescient combines 5D software, clever engineering, and advanced robotics to create prefabricated assemblies for apartment buildings and student housing.

AEC Innovators | Aug 27, 2019

7 AEC industry disruptors and their groundbreaking achievements

From building prefab factories in the sky to incubating the next generation of AEC tech startups, our 2019 class of AEC Innovators demonstrates that the industry is poised for a shakeup. Meet BD+C’s 2019 AEC Innovators.

AEC Tech | Aug 25, 2019

Deluxe parking: A condo building in Philadelphia offers its owners a completely automated parking service

This is the first “palletless” system that Westfalia Technologies has installed.

Codes and Standards | Aug 22, 2019

5G expected to give a boost to construction technology

Virtual reality, Internet of Things, robotics, and drones will all benefit from enhanced data flows.

AEC Innovators | Aug 15, 2019

Oracle’s replica of a construction jobsite creates an immersive environment for AEC professionals

The Oracle Construction and Engineering Innovation Lab allows visitors to walk through five different stages of construction work, to test new AEC technologies and training techniques.