A team of AEC firms, assembled by Generate, an AEC technology company that advocates for the greater use of mass timber in construction, has developed a digital catalog of integrated design systems that focus on the structural application of mass timber as a carbon-conscious response to high-density urban building needs, especially for housing.

Meeting those needs within the status quo—where buildings currently account to two-fifths of greenhouse gas emissions—is at odds with many cities’ environmental aspirations. For example, Boston’s goal of reducing its carbon footprint 80% by 2050 would be unachievable if that metro also hits its parallel goal of building 300,000 more housing units and 40 million sf of commercial buildings over the next 30 years.

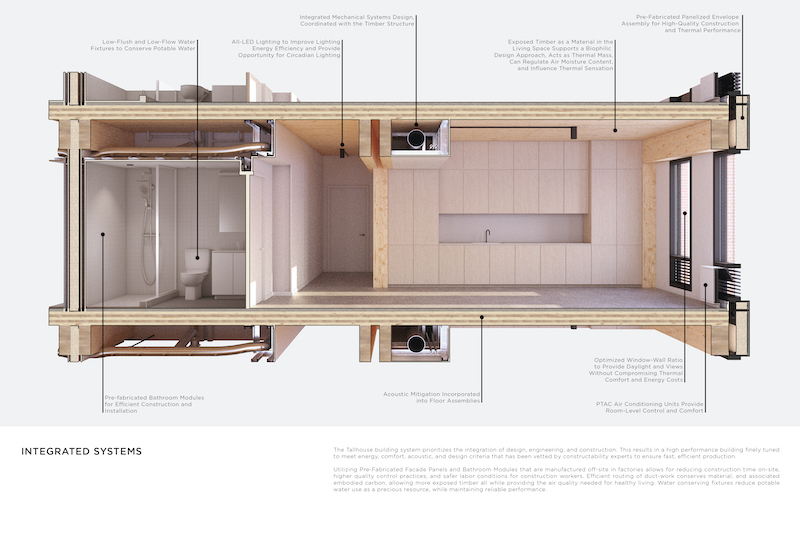

To bring down those CO2 emissions and streamline the construction process, an AEC coalition has developed Tallhouse, a digital catalog of customizable systems comprised of four mass timber structural solutions. That catalog illustrates a range of mass timber design options that are engineered for speedier delivery, sustainability, and cost savings.

Also see: San Jose affordable housing project will feature mass timber frame

The coalition includes Generate, Niles Bolton Associates (architect), Buro Happold (SE, MEP, sustainability consultant, embodied carbon analyst), Consigli Construction (GC), Arup (fire engineering, structural review), Code Red (code consultant), Urbanica (developer), and Olifant Market Development (carbon and forests).

The coalition’s work has been supported by the National Science Foundation, the U.S. Department of Agriculture, the Softwood Lumber Board, the Binational Softwood Lumber Council, and the Commonwealth of Massachusetts.

Tallhouse's systems are designed as kits of parts to accommodate most countries' products and transportation.

THE DESIGNS ANTICIPATE TALLER WOOD BUILDING CODES

Tallhouse’s four options are a hybrid steel/cross-laminated timber (CLT) structure, a mass-timber post, beam and plate structure; a hybrid light-gauge metal/CLT structure, and a full CLT plate honeycomb structure.

By “hybridizing” conventional construction materials with timber, the Tallhouse designs can offset near-term emissions by greatly reducing emissions from the manufacture of materials, while storing carbon in the timber structure over the lifetime of buildings. The team sees synergies between the steel and timber industries, as both materials lend themselves to digitization and carbon efficiency.

To evaluate each design, the coalition developed a Carbon Data Analysis tool that validated savings in embodied emissions ranging from 14% to 52%.

The coalition used a Carbon Data Analysis tool to gauge the impact of its designs on carbon emissions and global warming.

The Tallhouse system is adaptable for buildings eight to 18 stories, in line with the upcoming 2021 U.S. Tallwood Codes that would allow the use of mass timber for structures at those heights under the 2021 International Building Code. According to Generate, the systems are designed as kits of parts to accommodate most American, Canadian, and European manufacturers’ products and shipping logistics.

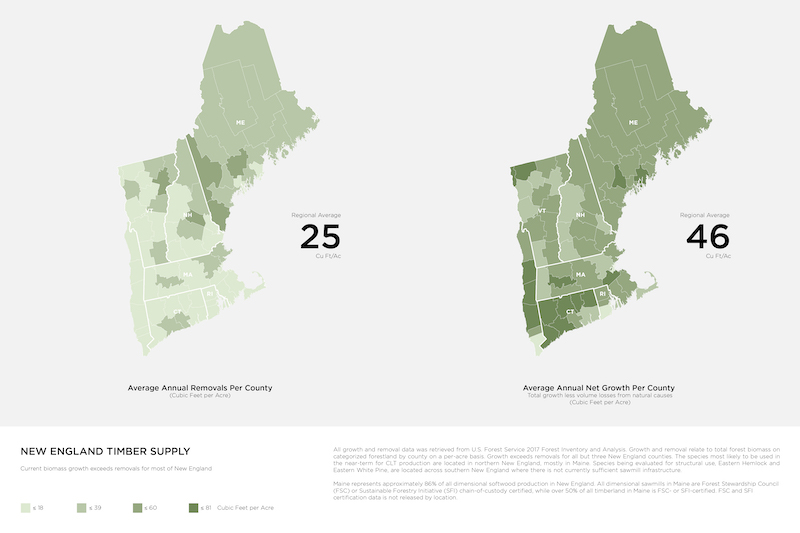

The U.S. Northeast is home to the highest percentage of sustainably managed timber in the U.S. Long-lived forest products such as mass timber building materials have longer timelines than paper or pulp products for keeping CO2 stored in wood post-harvesting.

The Tallhouse team is implementing these systems in over 1 million sf of construction in the U.S., and is looking for additional developers. The Tallhouse catalog, says John Klein, Generate’s CEO and project leader, “was developed with the specific intent of at once enabling our cities to achieve their ambitious CO2 footprint reduction goals, and to meet growing demand for affordable, biophilic housing.” As these systems become widely accessible to architectural communities globally, they will “serve as a vehicle to deploy sustainable materials at scale,” says Klein.

Related Stories

| Aug 11, 2010

Integrated Project Delivery builds a brave, new BIM world

Three-dimensional information, such as that provided by building information modeling, allows all members of the Building Team to visualize the many components of a project and how they work together. BIM and other 3D tools convey the idea and intent of the designer to the entire Building Team and lay the groundwork for integrated project delivery.

| Aug 11, 2010

Great Solutions: Products

14. Mod Pod A Nod to Flex Biz Designed by the British firm Tate + Hindle, the OfficePOD is a flexible office space that can be installed, well, just about anywhere, indoors or out. The self-contained modular units measure about seven feet square and are designed to serve as dedicated space for employees who work from home or other remote locations.

| Aug 11, 2010

Great Solutions: Technology

19. Hybrid Geothermal Technology The team at Stantec saved $800,000 in construction costs by embedding geothermal piping into the structural piles at the WestJet office complex in Calgary, Alb., rather than drilling boreholes adjacent to the building site, which is the standard approach. Regular geothermal installation would have required about 200 boreholes, each about four-inches in diameter ...