Museums, archives, and art storage facilities require special design consideration for a number of reasons, most notably that the value of the building’s contents often exceeds the value of the building itself. Even a minor shortfall in building performance with respect to heat, air, and moisture control can compromise the collections and lead to a multi-million dollar problem.

This column diagnoses the three most common moisture challenges with museums, archives, and art storage facilities and provides design guidance on how to avoid them.

1. Avoid severe swings in temperature and humidity

Museums, archives, and art storage facilities generally have strict requirements for interior temperature and relative humidity (RH) control. The unofficial museum standard for temperature and RH is 70°F and 50%.

While much attention is given to getting temperature and humidity levels just right, maintaining relatively constant conditions is generally more important than the levels themselves.

In fact, these set point recommendations are based more on anecdotes than on any rigorous testing or scientific evaluation. During World War II, conservators from the British Museum found that paintings hidden in slate quarry caves for protection experienced much slower degradation than when on display in the museum. The conditions in those caves—approximately 63°F and 58% RH—were loosely rounded to 60°F and 60% RH, and are considered the optimum museum environment for paintings. To account for occupant comfort and variability in collections, conservators established the ideal range for museums and libraries at 60-75°F and 50-65% RH.

In The Museum Environment, first published in 1978, author Garry Thomson stated that “modern day mechanical systems are capable of maintaining a year-round environment of 70° ±2°F, 50% ±5% RH.” Although Thomson does not declare that these conditions are ideal for storing artwork or other artifacts, those numbers and that publication have been considered the “museum standard” for years.

The fact is all materials have different ideal storage conditions. Limiting fluctuations in temperature and RH helps reduce mechanical stresses in the materials due to thermal- and moisture-related expansion and contraction. Materials such as wood and paper will expand and contract as their temperature and moisture content change. Large or sudden swings in those levels can induce stresses in the materials, leading to premature degradation.

2. Pay careful attention to fenestration and wall systems to avoid condensation

Museum environments typically have an interior dew point temperature of approximately 50°F—much higher than a typical office building or condominium—and this dew point is constantly maintained throughout the winter. In non-humidified buildings, the coldest exterior temperatures generally coincide with the driest interior conditions, reducing condensation risk in most cases. For museums, there is no corresponding drop in interior dew point at low exterior temperatures, thereby increasing the risk for condensation.

Condensation will form on interior surfaces that are colder than the ambient dew point temperature. While this is typically not a concern for walls with continuous insulation, framed walls with insulation placed between the studs may experience low interior surface temperatures due to thermal bridging through the framing. In relatively cold climates, such as the Northeast, thermal bridging in museum walls can drop interior surface temperatures to the point where condensation occurs.

The primary source of condensation, however, is fenestration. Aluminum windows, curtain walls, and skylights, even when thermally broken, often have interior frame temperatures below 50°F during colder winter periods. Although insulating glass is generally sufficient to prevent widespread condensation on the vision areas, condensation may still occur in some cases.

The most common cause of glass condensation is the use of interior shading devices, which can insulate the framing and glazing from interior heat, while allowing interior moisture to reach those surfaces. Depending on the shade configuration, surface temperatures may be 10-20°F colder than the fully exposed condition. This creates a dilemma for museum designers, as shading devices are often required to control light levels, provide “blackout” capability for special exhibits or functions, and filter out ultraviolet radiation to protect artifacts from fading and degradation.

In cold climates, designers should consider specifying shading devices integral to insulating glass units (i.e., “between the panes”) or fritted or coated/laminated glass to provide light control. If interior shades must be used, a source of heat, such as a fin-tube radiator below the window, should be provided to warm the space between the window and the shade while the shade is drawn.

Museums often contain design features such as large glazed walls and expansive skylight openings. Skylights pose a significant condensation risk due to their horizontal orientation, which contributes to additional heat loss via radiation at night. Skylights are often placed far from heat sources, which results in localized lower temperatures at the skylights. High-performance glazing and framing, integral condensate gutters, and local heat sources must be included in the design of museum skylights. A second option is to use interior laylights below the skylights, which create a captive airspace below the skylight that can either be heated or dehumidified to reduce condensation risk.

Another common source of condensation in museums is the moisture contained in moving airstreams. Air leakage across and within exterior walls can carry large amounts of moisture relatively far from the leakage site, creating the potential for widespread damage in a short amount of time. This is exacerbated by the typical pressure control scheme in museums, which tends to create positive interior pressure to prevent exterior contaminants from entering gallery or storage spaces. While positive pressure keeps contaminants out, it also forces moisture-laden air through any gaps in the envelope. Since maintaining negative interior pressure is rarely an option for a museum, a well-detailed, continuous air barrier must be installed to prevent air leakage and condensation. A continuous vapor retarder is also required for the enclosure, since moisture can diffuse through porous materials in the walls and roof system.

3. Specify an airtight enclosure to maintain humidity levels

In addition to carrying moisture, moving air, in the form of air leakage through the enclosure, also carries heat. If air leakage is severe enough, heat and moisture flows can cause variations in the interior temperature and RH. A daily swing of 10% RH due to cold, dry air infiltration could damage the museum contents and compromise the museum’s reputation—the ability to maintain interior environmental conditions within tight tolerances is often a prerequisite to borrow collections from other museums. An airtight enclosure combined with a well-designed mechanical system is necessary to maintain tight control over the interior conditions.

GETTING MUSEUM CONVERSIONS RIGHT

In many cases, buildings with historic or artistic significance are converted into museum spaces. Such buildings are typically older, solid masonry structures with little or no insulation and inefficient fenestration systems.

Adding insulation and vapor or air barriers to solid masonry structures can cause significant problems with moisture accumulation, condensation, and accelerated masonry degradation, since these materials interfere with the walls’ ability to “breathe.” To complicate matters, windows in these types of buildings may have historic significance and are required to remain in place. Without modifications, however, the existing enclosure cannot function effectively under humidified conditions.

Window condensation can often be addressed by installing new interior “storm windows” to provide thermal resistance and maintain the exterior appearance of the building. In this case, the interstitial space may also provide room for shading devices. The space must be slightly ventilated with outdoor air to prevent heat and moisture buildup, and the interior storm window should be airtight to minimize moisture flow and condensation. Drafty storm windows often result in heavy condensation or frost on the existing windows.

The simplest solution for walls is to place humidified spaces away from the walls, using those areas for corridor or other common space. If humidified space must be adjacent to masonry walls, a ventilated “art hanging wall” can be constructed inboard of the masonry and integrated with the building mechanical system. This ventilated wall allows artwork to be placed on exterior walls without the temperature and moisture fluctuations that would otherwise occur. Close coordination between the architect, enclosure consultant, and mechanical engineer is required for this system to be successful. Depending on the condition and configuration of the existing walls, insulation may be allowable in this system without negatively affecting the walls.

Museum design tips

The following must be considered when designing museums:

• Design enclosure systems must include air barrier, vapor retarder, and thermal insulation systems that are sufficient and continuous.

• Design mechanical systems must provide close control over interior temperature and RH levels.

• Avoid interior shading devices at windows. If shading devices are used, provide supplemental heat to windows to prevent condensation when the shades are drawn.

• Skylight systems should be high performance, with integral condensate gutters and a heat source near the skylight. Alternatively, a “buffer zone” of dry air between a skylight and laylight may be sufficient to prevent condensation problems.

About the Author

Sean O’Brien is a Senior Project Manager in the New York City office of Boston-based Simpson Gumpertz & Heger Inc. O’Brien specializes in building science and building envelope performance, including computer simulation of heat, air, and moisture migration issues. He has investigated and designed repairs for a variety of buildings types, from condominiums to art museums, and has published papers on topics including moisture migration in masonry wall systems and condensation resistance of windows and curtain walls. He can be reached at smobrien@sgh.com.

Related Stories

High-rise Construction | Feb 23, 2024

Designing a new frontier in Seattle’s urban core

Graphite Design Group shares the design for Frontier, a 540,000-sf tower in a five-block master plan for Seattle-based tech leader Amazon.

Construction Costs | Feb 22, 2024

K-12 school construction costs for 2024

Data from Gordian breaks down the average cost per square foot for four different types of K-12 school buildings (elementary schools, junior high schools, high schools, and vocational schools) across 10 U.S. cities.

MFPRO+ Special Reports | Feb 22, 2024

Crystal Lagoons: A deep dive into real estate's most extreme guest amenity

These year-round, manmade, crystal clear blue lagoons offer a groundbreaking technology with immense potential to redefine the concept of water amenities. However, navigating regulatory challenges and ensuring long-term sustainability are crucial to success with Crystal Lagoons.

Architects | Feb 21, 2024

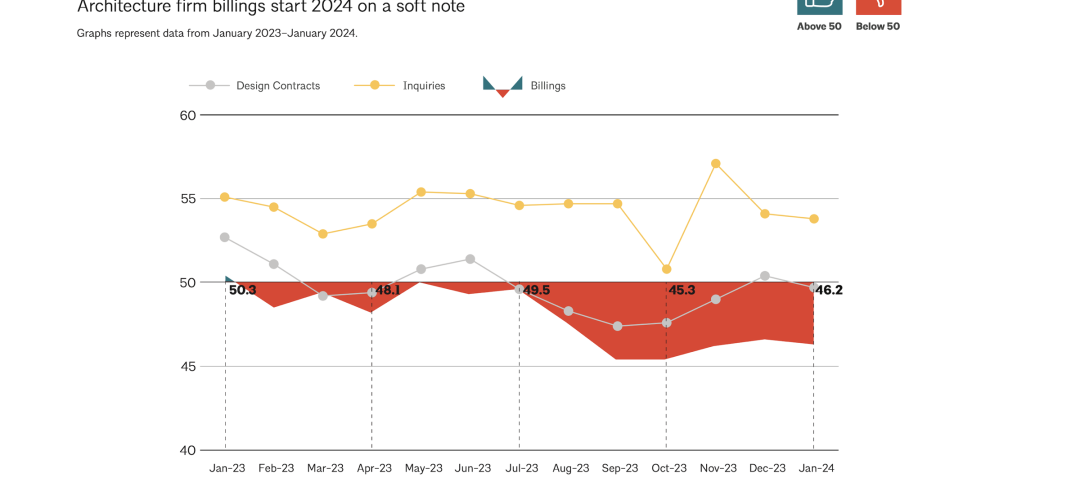

Architecture Billings Index remains in 'declining billings' state in January 2024

Architecture firm billings remained soft entering into 2024, with an AIA/Deltek Architecture Billings Index (ABI) score of 46.2 in January. Any score below 50.0 indicates decreasing business conditions.

University Buildings | Feb 21, 2024

University design to help meet the demand for health professionals

Virginia Commonwealth University is a Page client, and the Dean of the College of Health Professions took time to talk about a pressing healthcare industry need that schools—and architects—can help address.

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

Engineers | Feb 20, 2024

An engineering firm traces its DEI journey

Top-to-bottom buy-in has been a key factor in SSOE Group’s efforts to become more diverse, equitable, and inclusive in its hiring, mentoring, and benefits.

Building Tech | Feb 20, 2024

Construction method featuring LEGO-like bricks wins global innovation award

A new construction method featuring LEGO-like bricks made from a renewable composite material took first place for building innovations at the 2024 JEC Composites Innovation Awards in Paris, France.

Codes and Standards | Feb 20, 2024

AISC, AIA release second part of design assist guidelines for the structural steel industry

The American Institute of Steel Construction and AIA Contract Documents have released the second part of a document intended to provide guidance for three common collaboration strategies.

Student Housing | Feb 19, 2024

UC Law San Francisco’s newest building provides student housing at below-market rental rates

Located in San Francisco’s Tenderloin and Civic Center neighborhoods, UC Law SF’s newest building helps address the city’s housing crisis by providing student housing at below-market rental rates. The $282 million, 365,000-sf facility at 198 McAllister Street enables students to live on campus while also helping to regenerate the neighborhood.