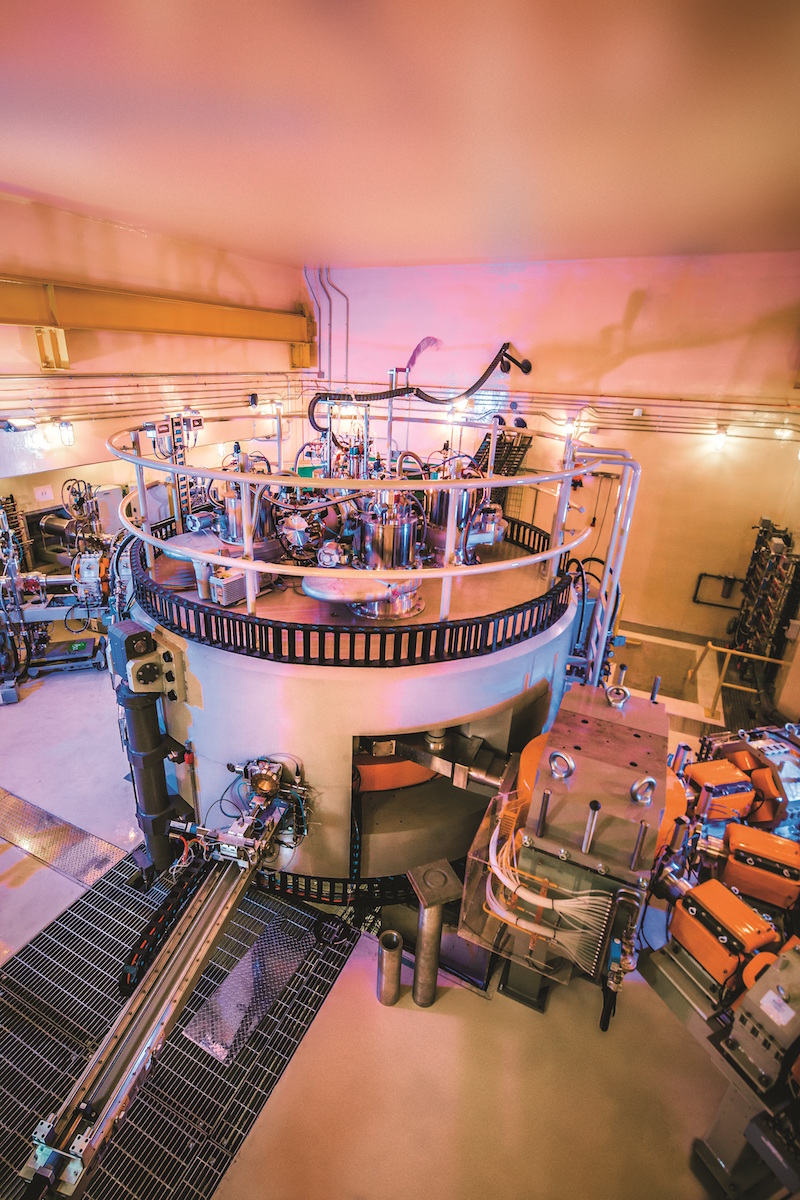

Zevacor Molecular, a healthcare firm that manufactures PET and SPECT radiopharmaceutical products, installed the first and largest commercial 70-million electron volt (MeV) cyclotron dedicated to producing medical isotopes for the global market. Based in Noblesville, IN, Zevacor’s primary focus is to manufacture Strontium 82 and Germanium 68, although it is capable of producing a wide variety of other radioisotopes (atoms with excess energy) for both research and clinical applications.

“Each of these drug products have a certain affinity within the body and will preferentially go to the targeted disease,” said Todd Hockemeyer, Vice President of Quality and Regulatory Affairs at Zevacor. “It’s kind of like a car and driver. The driver is the radioactive isotope connected to a chemical, the car, which will go to a certain place in the body. Often a PET scan is combined with a CT scan to match it up with your anatomical body to see which organs the radioactivity, and therefore the disease, might be located in.”

The 70 MeV, 140-ton cyclotron was manufactured by Ion Beam Applications (IBA) in Belgium. The cyclotron is housed in an 11,000-cubic-yard concrete vault with 300 tons of reinforcing steel rod. It required more than 1,300 trucks of concrete to complete the project. On one Saturday, over 300 trucks made one continuous pour to create the foundation, as this “raft” cannot shift and have a deflection of more than 1 mm without degrading the energy beam.

Manufacturing Strontium 82 requires a lot of energy. Most of the equipment involved in the process is powered pneumatically with compressed air, but Zevacor estimates its annual power bill at $1 million, with three-fourths of that energy spent cooling water to keep the cyclotron and targets from overheating.

Viega ProPress was used on the HVAC lines

Viega ProPress was used on the HVAC lines

“The heat from highly purified water used to cool the targets and critical cyclotron components is transferred to another isolated chill system filled with purified water,” Hockemeyer said, “which is then cooled by a chill water system using water from the local utility.”

The cyclotron is housed with six other vaulted areas, each supplied with two separate sets of copper pipes—one for feed water to make the purified water supply and the other to extract the heat. Because purified water is extremely corrosive to copper, the copper pipe does not come in contact with that water. It only goes to the filtration system that purifies the water upon which it is transferred to the target through a PVC line.

“The integrity of that chilled water system is critical,” Hockemeyer said. “If the cooling system shuts down, so does our cyclotron.”

That’s why Zevacor chose Viega ProPress for copper over soldering.

“We understood how important it was to have highly purified water and a water containment system that’s reliable and doesn’t leak and doesn’t fail,” Hockemeyer said. “The cost of a failure is far in excess of any money we might shave off the installation process because we used welded fittings.”

Zevacor also chose Viega to reduce the danger of contamination and particles in the piping, which can become radioactive and create different problems with hazardous waste water.

Viega

800.976.9819

insidesales@viega.us

For the complete story, visit the Viega website here.

Related Stories

Intelligent Lighting | Feb 13, 2023

Exploring intelligent lighting usage in healthcare, commercial facilities

SSR's Todd Herrmann, PE, LEEP AP, explains intelligent lighting's potential use cases in healthcare facilities and more.

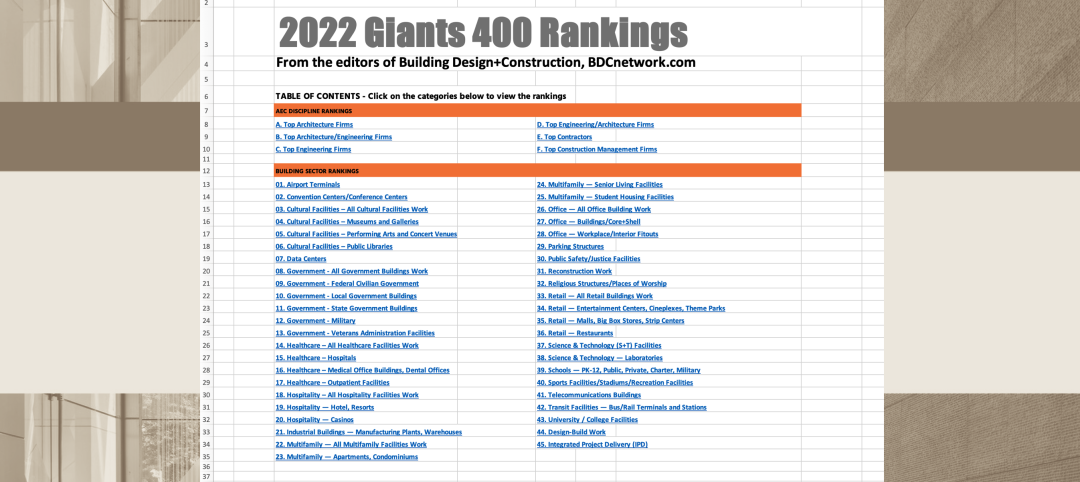

Giants 400 | Feb 9, 2023

New Giants 400 download: Get the complete at-a-glance 2022 Giants 400 rankings in Excel

See how your architecture, engineering, or construction firm stacks up against the nation's AEC Giants. For more than 45 years, the editors of Building Design+Construction have surveyed the largest AEC firms in the U.S./Canada to create the annual Giants 400 report. This year, a record 519 firms participated in the Giants 400 report. The final report includes 137 rankings across 25 building sectors and specialty categories.

Giants 400 | Feb 6, 2023

2022 Reconstruction Sector Giants: Top architecture, engineering, and construction firms in the U.S. building reconstruction and renovation sector

Gensler, Stantec, IPS, Alfa Tech, STO Building Group, and Turner Construction top BD+C's rankings of the nation's largest reconstruction sector architecture, engineering, and construction firms, as reported in the 2022 Giants 400 Report.

Healthcare Facilities | Jan 31, 2023

How to solve humidity issues in hospitals and healthcare facilities

Humidity control is one of the top mechanical issues healthcare clients face. SSR's Lee Nordholm, PE, LEED AP, offers tips for handling humidity issues in hospitals and healthcare facilities.

Augmented Reality | Jan 27, 2023

Enhancing our M.O.O.D. through augmented reality therapy rooms

Perkins Eastman’s M.O.O.D. Space aims to make mental healthcare more accessible—and mental health more achievable.

Hospital Design Trends | Jan 19, 2023

Maximizing access for everyone: A closer look at universal design in healthcare facilities

Maria Sanchez, Interior Designer at Gresham Smith, shares how universal design bolsters empathy and equity in healthcare facilities.

Fire and Life Safety | Jan 9, 2023

Why lithium-ion batteries pose fire safety concerns for buildings

Lithium-ion batteries have become the dominant technology in phones, laptops, scooters, electric bikes, electric vehicles, and large-scale battery energy storage facilities. Here’s what you need to know about the fire safety concerns they pose for building owners and occupants.

Healthcare Facilities | Dec 20, 2022

4 triage design innovations for shorter wait times

Perkins and Will shares a nurse's insights on triage design, and how to help emergency departments make the most of their resources.

Healthcare Facilities | Dec 20, 2022

Designing for a first-in-the-world proton therapy cancer treatment system

Gresham Smith begins designing four proton therapy vaults for a Flint, Mich., medical center.

Cladding and Facade Systems | Dec 20, 2022

Acoustic design considerations at the building envelope

Acentech's Ben Markham identifies the primary concerns with acoustic performance at the building envelope and offers proven solutions for mitigating acoustic issues.