As the coronavirus stubbornly persists in many parts of the U.S., COVID-19-specific buildings and products have been popping up in response.

Last January, Medline Industries, the largest privately held manufacturer and distributor of medical supplies in the U.S., started making face masks for the first time from a modified plant in Lithia, Ga., that, when fully operational later this year, will produce 36 million masks per month.

To support its core business units, Medline recently completed construction of a 130,000-sf, LEED-certified call center in Dubuque, Iowa, with over 1,000 workstations.

Medline's call center has over 1,000 workstations and is adding over 100 jobs to the market. Image: Charlie Mayer Photography

Medline's call center has over 1,000 workstations and is adding over 100 jobs to the market. Image: Charlie Mayer Photography

Working with the architecture design firm Ware Malcomb and general contractor Alston Construction, Medline’s goal for the call center was to create a “town within a town.” For example, adjacent to the cafeteria is a light-filled corner city center with access to an outside patio. A 5,200-sf gym/multipurpose room with a full-size basketball court is available to all employees. To encourage activity, the space includes a quarter mile track around the interior of the open office.

“It was our priority that the entire facility emphasizes connectivity and community,” says Dawn Riegel, Director, Interior Architecture and Design of Ware Malcomb’s Chicago and Oak Brook., Ill., offices. The call center added over 100 new jobs to the Dubuque market.

GETTING MORE PEOPLE VACCINATED FASTER

As of April 1, 29% of Americans had received one dose of the COVID-19 vaccine and 16% had received two doses, according to the Centers for Disease Control and Prevention. About 2.5 million people per day are being vaccinated, but the logistics of administering shots are still challenging for some municipalities and cities.

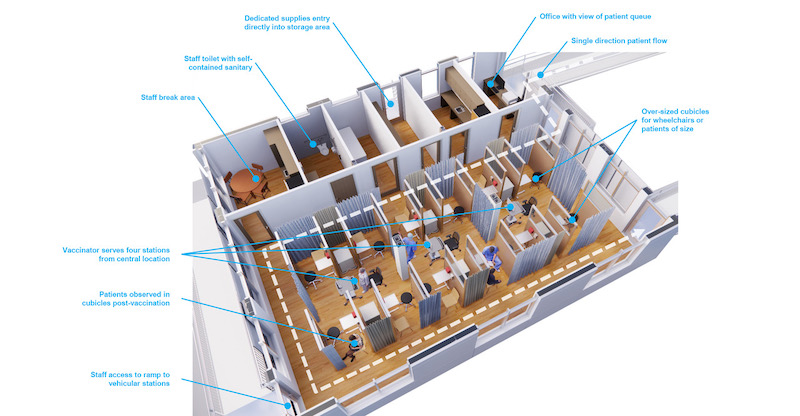

Among the solutions that have come onto the market is VaxMod, a modular system devised by the design firm Boulder Associates, which specializes in healthcare and senior living, and manufacturer The Boldt Company. VaxMod’s prefabricated units can provide safe and efficient COVID-19 vaccination settings for healthcare workers and individuals, and are set up for speedier delivery.

VaxMod consists of three modules, each 12- by 40-ft, although customers are allowed some tailoring. VaxMods can function as freestanding units or be connected to each other with segregated spaces for healthcare workers and patients.

According to The Boldt Company, VaxMod can vaccinate more than 1,100 patients per eight-hour shift with 27 full-time employees. That’s 39% more vaccines delivered per hour with 7% fewer staff than model vaccination clinics identified by the CDC. VaxMod is designed to handle both walk-in and drive-through patients, and is scalable to meet a specific community’s patient volume.

DRIVE THRU OR WALK-IN SERVCE

VaxMod is set up to deliver 1,100 vaccine shots during an eight-hour shift with only 27 workers. Image: The Boldt Company

VaxMod is set up to deliver 1,100 vaccine shots during an eight-hour shift with only 27 workers. Image: The Boldt Company

More precisely, VaxMod can be configured as a drive-through hub with a capacity for 104 vehicular vaccinations per hour. All traffic enters at one point for temperature and health screening. Individuals can check in and register for either walk-in or in-vehicle vaccinations. Canopies and covered stalls can be arranged in two loops around the central VaxMod, providing shelter for vehicles and resupply points for workers.

Simultaneously, VaxMod can serve 35 walk-in individuals per hour. Each unit houses 12 vaccination stations with specialized accommodations for individuals in wheelchairs. Individual cubicles are designed for privacy, social distance, and observation space after the vaccine is administered.

Boldt is cultivating sometimes of a specialty in the COVID arena. Last year, Boldt and the design firm HGA developed STAAT Mod, a prefabricated temporary hospital to help healthcare systems manage surge capacity during health crises. STAAT is short for Strategic Accuity-Adaptable Treatment, and the isolation rooms were designed with enough clearance for safe bed transfers, equipment, and a reclining chair. Boldt produces STAAT Mod and VaxMod modules in its Appleton, Wis., plant.

Also see: BD+C’s reporting on STAAT Mod

“Our experience in prefabrication means we can manufacture these facilities with better speed to market,” said Will Lichtig, executive vice president and chief of staff with The Boldt Company. “This allows us intense quality control, increased safety for our workforce, and the ability to meet an urgent need for healthcare organizations and our communities.”

Related Stories

Coronavirus | Apr 15, 2020

COVID-19 alert: 93% of renters in professionally managed multifamily housing paid some or all of their rent, says NMHC

In its second survey of 11.5 million units of professionally managed apartment units across the country, the National Multifamily Housing Council (NMHC) found that 84% of apartment households made a full or partial rent payment by April 12, up 15 percentage points from April 5.

Coronavirus | Apr 15, 2020

DCAMM teams with SLAM and Gilbane Building Company to re-occupy Newton Pavilion for temporary quarantine of homeless during COVID-19 pandemic

First and only quarantine shelter in Boston-area to convert a shuttered hospital for homeless patient occupancy.

Coronavirus | Apr 15, 2020

3D printing finds its groove fabricating face shields during COVID-19 crisis

The architecture firm Krueck + Sexton is producing 100 shields for a Chicago-area hospital.

Coronavirus | Apr 14, 2020

COVID-19 alert: Missouri’s first Alternate Care Facility ready for coronavirus patients

Missouri’s first Alternate Care Facility ready for coronavirus patients

Coronavirus | Apr 13, 2020

COVID-19 alert: City conducts a 'virtual building inspection' to allow Starbucks and bank to open

Bothell, Wash., issues a certificate of occupancy to developer after inspecting the property online.

Coronavirus | Apr 13, 2020

Construction layoffs spread rapidly as coronavirus shuts down projects, in contrast to job gains through February in most metros

Association officials urge quick enactment of infrastructure investment, relief for hard-hit firms and pensions in order to save jobs in construction and supplier industries.

Coronavirus | Apr 12, 2020

How prefab can enable the design and construction industry to bring much needed beds to hospitals, faster

The outbreak of COVID-19 represents an unprecedented test for the global healthcare system. Managing the pandemic—and saving lives—depends largely on the availability of medical supplies, including the capacity of hospitals. But the United States lags behind other nations, with only 2.8 beds per thousand people compared to 4.3 in China and 12.8 in South Korea.

Coronavirus | Apr 10, 2020

HGA and The Boldt Company devise a prefabricated temporary hospital to manage surge capacity during a viral crisis

A STAAT Mod system can be ready to receive patients in less than a month.

Coronavirus | Apr 10, 2020

COVID-19: Converting existing hospitals, hotels, convention centers, and other alternate care sites for coronavirus patients

COVID-19: Converting existing unused or underused hospitals, hotels, convention centers, and other alternate care sites for coronavirus patients

Coronavirus | Apr 9, 2020

COVID-19 Design Innovation Grant: IDA offers $14,000 to spur design innovation for combating the coronavirus pandemic

The International Design Awards is looking for innovations in low-cost ventilators, in-home isolation pods, and reusable masks.