HMC Architects is among the latest design brands to manufacture face shields for healthcare workers in response to the ongoing coronavirus crisis.

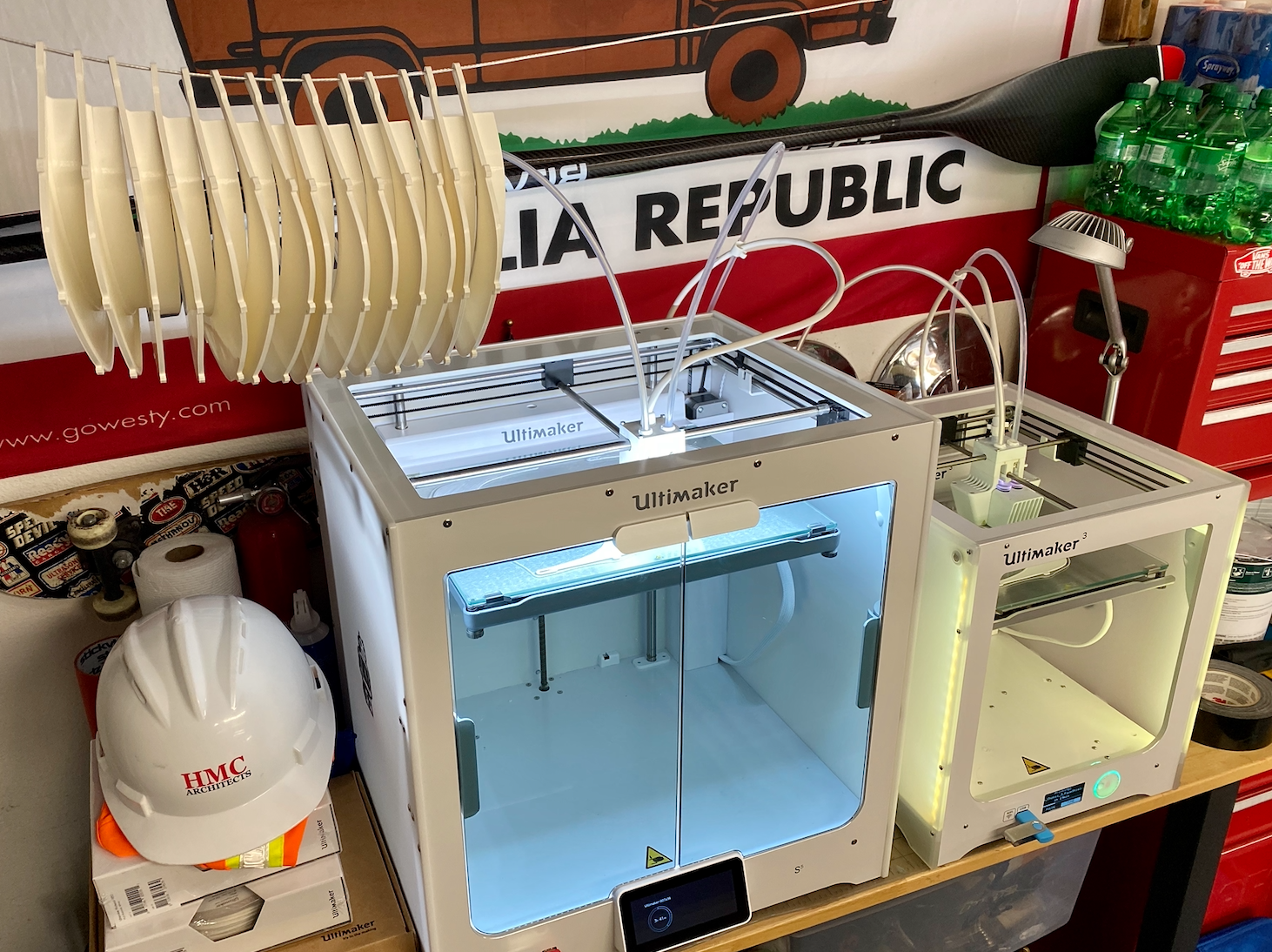

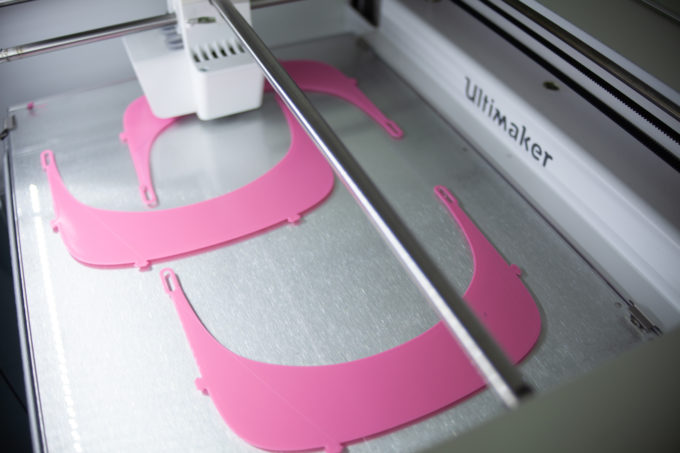

Using the Columbia University Library Studios information as a guide, the design firm is applying its fabrication capabilities and Ultimaker 3D printers to manufacture PPE face shields and make them available to hospitals and clinics in its communities.

An Ultimaker 3D printer at a remote fabrication site being operated by self-isolated HMC employees.

An Ultimaker 3D printer at a remote fabrication site being operated by self-isolated HMC employees.

“If there was any time for innovative design firms to step up and provide resources to our communities, it’s right now,” said HMC President and CEO Brian Staton. “We hope to distribute as many as we can to support the efforts of our heroic healthcare workers.”

With its Ultimaker 3 and Ultimaker 5S printers running all day, every day from work-from-home locations in Los Angeles, San Diego, San Jose, Sacramento, and Ontario, Calif., HMC designers are estimating up to 35 face shields per day.

See the brief video demonstration:

3 PARTS NEEDED FOR MAKING FACE SHIELDS

The face shields are made up of three parts:

1. An elastic headband holding the shield in place on the healthcare worker’s head.

2. A 3D-printed headband connecting the elastic to the transparent shield that rests on the healthcare worker’s forehead.

3. A transparent shield made of PETG (a thin, clear, impermeable plastic).

Using 3D models from the Columbia University Library Studios website, the firm has been able to coordinate a lot of data to fabricate the 3D-printed headband that connects the elastic to the shield. The HMC teams have been using Cura open-source software to optimize print times and get higher quantities out of the 3D printers.

HMC is sourcing the face shield material (PETG 30 mil sheet material) from Riverside Plastics, a local Southern California plastic supplier. Other materials, such as elastic straps for the headbands and Ziploc bags for packaging, are being sourced from local hardware and fabric retailers.

Face shield parts fabricated by remotely sited HMC staff using 3D printers.

Face shield parts fabricated by remotely sited HMC staff using 3D printers.

HMC designers are following strict contamination guidelines during production, constantly sanitizing the shields and packaging them for distribution. The firm is putting together a distribution strategy and are in the process of connecting with healthcare organizations most in need and plans to begin distributing the face shields by next week. HMC has also been in touch with other local architecture firms in the hopes that their work inspires others to join their effort.

The designers have already made improvements to their original prototypes. They changed to closed-cell foam after having some concerns about the sterility of open-cell weather stripping as specified on the Columbia University website. A local contact stepped up to provide the closed-cell foam, which is not always readily available.

DESIGN BRANDS RESPONDING TO PPE SHORTAGE

HMC joins the list of other innovative design brands—notably Under Armour, New Balance, Chanel, and Ralph Lauren—to find creative ways to respond to the personal protective equipment shortage caused by COVID-19.

Related Stories

Office Buildings | Mar 26, 2021

Finding success for downtown office space after COVID-19

Using the right planning tools can spur new uses for Class B and C commercial real estate.

Coronavirus | Mar 11, 2021

The Weekly show, March 11, 2021: 5 building products for COVID-related conditions, and AI for MEP design

This week on The Weekly show, BD+C editors speak with AEC industry leaders about building products and systems that support COVID-related conditions, and an AI tool that automates the design of MEP systems.

Coronavirus | Feb 24, 2021

COVID-19 spurs need for specific building solutions

A medical supply house’s new call center and a vaccination module that can handle more patients faster are among the latest projects.

Healthcare Facilities | Feb 5, 2021

Healthcare design in a post-COVID world

COVID-19’s spread exposed cracks in the healthcare sector, but also opportunities in this sector for AEC firms.

Data Centers | Jan 21, 2021

The Weekly show, Jan 21, 2021: Data centers in a pandemic world, and LGBT certification for AEC firms

This week on The Weekly show, BD+C editors speak with AEC industry leaders about LGBT certification for architecture, engineering, and construction firms, and the current state of data centers in a pandemic world.

Multifamily Housing | Jan 8, 2021

Student housing development in the time of COVID-19

Despite the coronavirus pandemic, many college and university residences were completed in time for classes, live or virtual. Here are 14 of the best.

Healthcare Facilities | Dec 10, 2020

The Weekly show: The future of medical office buildings, and virtual internship programs

This week on The Weekly show, BD+C editors spoke with leaders from SMRT Architects and Engineers and Stantec about the future of medical office buildings, and virtual internship programs

AEC Tech | Dec 8, 2020

COVID-19 affects the industry’s adoption of ConTech in different ways

A new JLL report assesses which tech options got a pandemic “boost.”

Multifamily Housing | Dec 4, 2020

The Weekly show: Designing multifamily housing for COVID-19, and trends in historic preservation and adaptive reuse

This week on The Weekly show, BD+C editors spoke with leaders from Page & Turnbull and Grimm + Parker Architects about designing multifamily housing for COVID-19, and trends in historic preservation and adaptive reuse