When Sara Lee Corp. changed its name to Hillshire Brands and relocated from the suburbs to downtown Chicago in December 2012, the company gained a new lease on life.

Hillshire moved a portion of its corporate headquarters into the newly renovated, four-story 400 South Jefferson Street building in the city’s West Loop. Built in 1944 for the Newman-Rudolph Lithographing Co., the 230,000-sf structure was stripped down to its cast-in-place concrete frame and rebuilt with a modern glass curtain wall façade, new passenger elevators, major building system updates, and an indoor parking garage.

The $70 million, fast-track project—led by Proteus Group (architect, core and shell), Leopardo (general contractor, core and shell), Perkins+Will (architect, interior build-out), Clune (general contractor, interior build-out), Sterling Bay Cos. (owner/developer), Environmental Systems Design (MEP/FP), Project Management Advisors (project management), and Colliers (tenant representative)—was completed in just 10 months using a BIM/VDC/IPD workflow.

The core and shell team had the full 10 months to complete its portion of the project, but the interior build-out team had just four months. The interior work entailed four general office floors, three test kitchens, and a tower housing conference rooms.

Initially, the base building contractor modeled the as-built conditions using BIM, after which the interior design was added by Perkins+Will, before releasing the model to Environmental Systems Design. ESD had just four weeks to complete bid and permit documentation for the building’s MEP and fire protection systems.

5 Tips for collaborating with BIM

1. All consultants working in BIM should coordinate during architectural model development, rather than after completion of the architectural model. Communicating your expectations prevents coordination issues from occurring later in the project design. In the case of the Hillshire HQ project, the architects and engineers met before the BIM model was initiated to talk about past concerns and project design expectations.2. Set up trade drawing sheets at the start of the project. Designers often forget to set up trade drawing sheets and don’t think about them until the end of the project when they want to print. The absence of trade drawing sheets can hold up a project. As cool as the 3D model is, the 2D drawing is what everyone will use after the design has been completed.3. BIM programs are not CAD; don’t use them as if they were. Most AEC professionals learn how to design in 2D CAD, so when moving into BIM they try to replicate what is done in CAD, like drawing text boxes, without utilizing the “smarts” in BIM. In addition, understand that you’re working in a 3D environment and you need to pay attention to the “Z” axis, or the vertical plane. For the first time, height needs to be defined. How high are you mounting the ductwork or the light fixture? Those questions need to be answered early on.4. Use BIM to create ventilation schedules. Take advantage of the information already held in the model, such as the defined volume and ceiling height of each room. Let the BIM model fill out ventilation schedules and calculate air quantities of individual air terminals.5. Set up electrical equipment properties and panel schedules at the beginning. This speeds up circuiting in the end. Every time a piece of equipment is placed into the BIM model, fill in the information about the piece of equipment from the start so that schedules auto-populate at the end.— Amanda Carter

Could BIM really speed up design, eliminate coordination issues among the trades, and limit requests for information during construction? ESD set out to find the answer.

Beginning with Autodesk’s Revit MEP, ESD engineers created a 3D interactive model. Using Revit’s automatic scheduling feature, they simulated the building’s potential loads, including air quantities and electrical loads. Defining the space types and square footage of each room within the model allowed BIM to automatically calculate the ventilation requirements of the applicable mechanical codes for each space. These quantities were scheduled and allowed the mechanical engineers to assure that the proper amount of supply air would be provided to each room.

Similarly, by defining specific loads and demand factors for the electrical elements within the Revit model, the panel schedules were able to self-populate and properly calculate both the total connected and demand load for each piece of electrical equipment in the building. This allowed for proper sizing of over-current protection for each piece of equipment throughout the electrical distribution, as well as the associated feeders and conduit.

Because each of the schedules was based on the definition of elements within the model, they were able to self-populate and automatically update to changes, allowing for fewer coordination issues within the construction documents. The model also helped the team lay out the ductwork so that it coordinated with light fixture locations in the building’s open ceiling layout, and ensured that the design of the electrical equipment met the dimensions of the designated equipment areas.

Together, these elements produced a complete model of the building’s MEP infrastructure with much more certainty than the traditional 2D modeling, and did so within the tight time frame.

Unfortunately, however, BIM can’t read the human mind. When the base building contractor altered the layout of the large electrical rooms in the field, the project’s contractor couldn’t build out the space as designed by ESD, per the base building model. Switches and equipment were housed in different locations within the space, resulting in an RFI that required re-coordination.

After the contractor in the field proposed a couple of options for the final equipment layout and ESD submitted the redesign, the large electrical rooms were built within the desired time frame. Despite this challenge, using BIM to coordinate between trades on the front end still resulted in fewer RFIs and allowed the Building Team to meet the tight design and construction schedule, avoiding major discrepancies in the field.

Comparing 2D to 3D for Performance

As a comparison, ESD previously designed a similar project in 2D CAD. This second project employed the same lead engineers and interiors contractors, with similar square footage and a large commercial kitchen, and was designed and constructed as the base building was being completed. The result? The Hillshire headquarters had approximately half the RFIs of the 2D-designed project.

To further test the success of BIM in the field, ESD selected a few locations throughout the Hillshire headquarters where “snapshots” of the Revit model were compared to post-construction photos of the same space. In every case, side-by-side visual comparisons showed that the construction documents were almost identical to what was installed in the field. Considering the speed at which both design and construction were completed, it was amazing that the end result so closely matched the original design.

While BIM was used on the project primarily to coordinate between trades during design, in the end, it helped the entire Building Team meet a tight schedule, eliminate coordination problems between the trades, and limit RFIs in the field.

Amanda Carter, FE, is an Electrical Engineer and Associate at Environmental Systems Design, Chicago (www.esdesign.com). She can be reached at acarter@esdglobal.com.

Related Stories

Office Buildings | Dec 1, 2023

Amazon office building doubles as emergency housing for Seattle families

The unusual location for services of this kind serves over 300 people per day. Mary's Place spreads across eight of the office's floors—all designed by Graphite—testing the status quo for its experimental approach to homelessness support.

Engineers | Nov 27, 2023

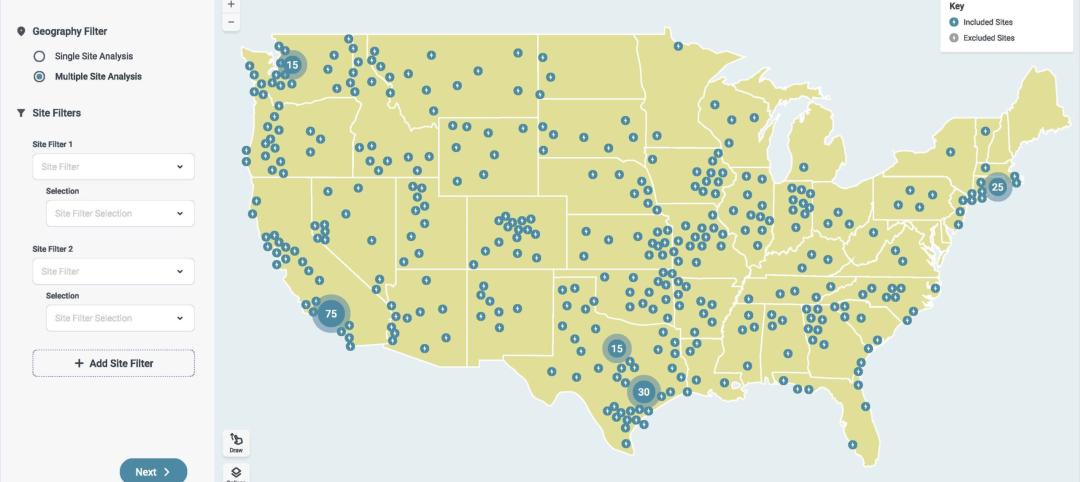

Kimley-Horn eliminates the guesswork of electric vehicle charger site selection

Private businesses and governments can now choose their new electric vehicle (EV) charger locations with data-driven precision. Kimley-Horn, the national engineering, planning, and design consulting firm, today launched TREDLite EV, a cloud-based tool that helps organizations develop and optimize their EV charger deployment strategies based on the organization’s unique priorities.

Market Data | Nov 27, 2023

Number of employees returning to the office varies significantly by city

While the return-to-the-office trend is felt across the country, the percentage of employees moving back to their offices varies significantly according to geography, according to Eptura’s Q3 Workplace Index.

Resiliency | Nov 27, 2023

All levels of government need to act to cope with climate-driven flooding and sea level rise

The latest National Climate Assessment highlights the need for local, state, and federal governments to adopt policies to mitigate the effects of climate-driven flooding and sea level rise, according to a policy expert with the National Resources Defense Council.

MFPRO+ New Projects | Nov 21, 2023

An 'eco-obsessed' multifamily housing project takes advantage of downtown Austin’s small lots

In downtown Austin, Tex., architecture firm McKinney York says it built Capitol Quarters to be “eco-obsessed, not just eco-minded.” With airtight walls, better insulation, and super-efficient VRF (variable refrigerant flow) systems, Capitol Quarters uses 30% less energy than other living spaces in Austin, according to a statement from McKinney York.

MFPRO+ News | Nov 21, 2023

California building electrification laws could prompt more evictions and rent increases

California laws requiring apartment owners to ditch appliances that use fossil fuels could prompt more evictions and rent increases in the state, according to a report from the nonprofit Strategic Actions for a Just Economy. The law could spur more evictions if landlords undertake major renovations to comply with the electrification rule.

Codes and Standards | Nov 21, 2023

Austin becomes largest U.S. city to waive minimum parking requirements

Austin, Texas recently became the largest city in the United States to stop requiring new developments to set a minimum amount of parking. The Austin City Council voted 8-2 earlier this month to eliminate parking requirements in an effort to fight climate change and spur more housing construction as Texas’s capitol grapples with a housing affordability crisis.

MFPRO+ News | Nov 21, 2023

Underused strip malls offer great potential for conversions to residential use

Replacing moribund strip malls with multifamily housing could make a notable dent in the housing shortage and revitalize under-used properties across the country, according to a report from housing nonprofit Enterprise Community Partners.

Retail Centers | Nov 15, 2023

Should retail developers avoid high crime areas?

For retailers resolute to operating in high crime areas, design elements exist to mitigate losses and potentially deter criminal behavior.

MFPRO+ News | Nov 15, 2023

Average U.S multifamily rents drop $3 to $1,718 in October 2023: Yardi Matrix

Multifamily fundamentals continued to soften and impact rents last month, according to the latest Yardi Matrix National Multifamily Report. The average U.S. asking rent dropped $3 to $1,718 in October, with year-over-year growth moderating to 0.4%, down 40 basis points from September. Occupancy slid to 94.9%, marking the first decline in four months.