It seems like a bit of modern day magic. Tap a few keys on your keyboard, perhaps with an accompanying mouse click or two, and then, voila!, one to two days later that new bestseller, necktie, or roll of novelty toilet paper you ordered is at your front door. And here you were thinking Santa Claus wasn’t real.

Okay, so maybe Santa has nothing to do with it, but it can be easy to forget those items you ordered didn’t just materialize out of thin air as if they were transported from the bridge of the Starship Enterprise. Sure, you clicked "Order" on Amazon, Target, or Walmart’s website, but what happens next? More likely than not, after your order information was received, the product had to be retrieved from a big box warehouse.

A big box warehouse is a facility that is over 300,000-sf with 28-foot ceilings or higher. These warehouses are commonly used among retailers to store products awaiting purchase by online consumers. As more and more sales start to take place online, retailers are beginning to adjust their distribution networks accordingly, The Wall Street Journal reports.

In 2015, 61 million sf of these big box warehouses were constructed in North America. That marks an increase of almost 6 times in a four-year span, according to Colliers International Group. There isn’t expected to be any slowdown in 2016, either, as an additional 74 million sf are projected to be completed by the end of the year.

Home Depot, Target Corp., and Wal-Mart Stores Inc. all felt the need, due to the uptick in online shopping, to build huge fulfillment centers meant to store, pack, and ship items to online customers.

These large warehouses aren’t necessarily out in the middle of nowhere, either. As one- and two-day deliveries become the standard for much of the country, building close to large population centers, ports, and rail lines is becoming imperative. There is 16.2 million sf of big box construction occurring in the Los Angeles area alone, and Eastern Pennsylvania and New Jersey aren’t far behind, with 13.3 million sf under construction.

Additionally, there is a trend toward building slightly smaller warehouses, in the 200,000-sf range, in high population urban zones to increase the speed at which online customers can receive their purchases even further. Some Amazon customers are able to get their deliveries a mere one to two hours after making the purchase.

These big box warehouses and their smaller-sized counterparts aren’t acting as a snake eating its own tail, either. Instead, they are working in tandem as a “two-pronged approach,” according to Dwight Hotchkiss, National Director of U.S. Industrial Services for Colliers. The smaller warehouses are able to satisfy one-hour delivery to urban markets while the big box warehouses handle one-day and same-day e-commerce.

While they might not be as rare (and becoming less so every day) or whimsical as Santa’s workshop, these big box warehouses are basically the real world equivalent. And as more of them are created close to urban centers, you won’t have to wait until the holidays to receive your packages. At the pace these big box warehouses are being created, you might not even have to wait until tomorrow.

Related Stories

| Apr 9, 2014

Steel decks: 11 tips for their proper use | BD+C

Building Teams have been using steel decks with proven success for 75 years. Building Design+Construction consulted with technical experts from the Steel Deck Institute and the deck manufacturing industry for their advice on how best to use steel decking.

| Apr 2, 2014

8 tips for avoiding thermal bridges in window applications

Aligning thermal breaks and applying air barriers are among the top design and installation tricks recommended by building enclosure experts.

| Mar 26, 2014

Callison launches sustainable design tool with 84 proven strategies

Hybrid ventilation, nighttime cooling, and fuel cell technology are among the dozens of sustainable design techniques profiled by Callison on its new website, Matrix.Callison.com.

| Mar 20, 2014

Common EIFS failures, and how to prevent them

Poor workmanship, impact damage, building movement, and incompatible or unsound substrate are among the major culprits of EIFS problems.

| Mar 20, 2014

Fluor defines the future 7D deliverable without losing sight of real results today

A fascinating client story by Fluor SVP Robert Prieto reminds us that sometimes it’s the simplest details that can bring about real results today—and we shouldn’t overlook them, even as we push to change the future state of project facilitation.

| Mar 19, 2014

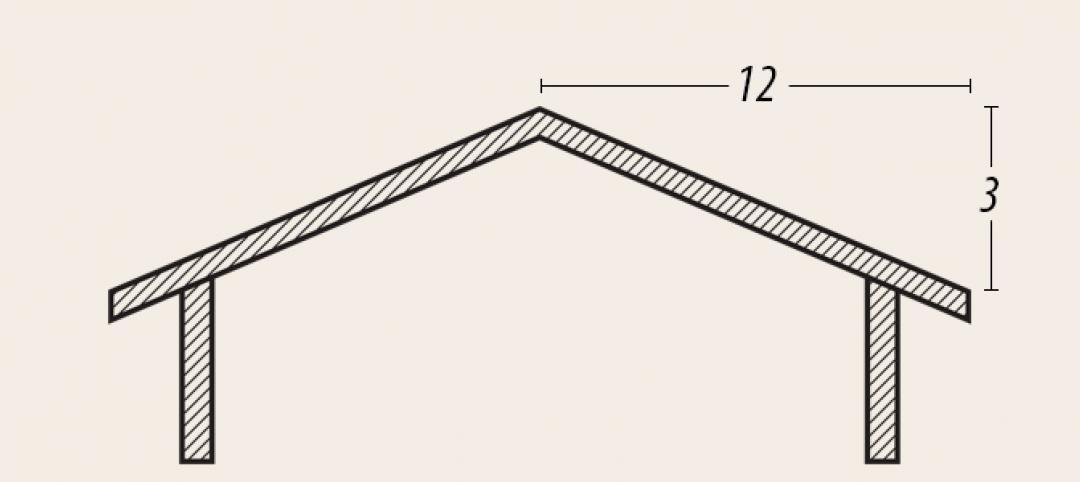

Frames: the biggest value engineering tip

In every aspect of a metal building, you can tweak the cost by adjusting the finish, panel thickness, and panel profile. These changes might make a few percentage points difference in the cost. Change the framing and you have the opportunity to affect 10-20 percent savings to the metal building portion of the project.

| Mar 12, 2014

14 new ideas for doors and door hardware

From a high-tech classroom lockdown system to an impact-resistant wide-stile door line, BD+C editors present a collection of door and door hardware innovations.

Sponsored | | Mar 10, 2014

A high-performance barn

Bastoni Vineyards replaces a wooden barn with an efficient metal building used for maintenance, storage, and hosting events.

| Jan 28, 2014

16 awe-inspiring interior designs from around the world [slideshow]

The International Interior Design Association released the winners of its 4th Annual Global Excellence Awards. Here's a recap of the winning projects.

| Jan 13, 2014

Custom exterior fabricator A. Zahner unveils free façade design software for architects

The web-based tool uses the company's factory floor like "a massive rapid prototype machine,” allowing designers to manipulate designs on the fly based on cost and other factors, according to CEO/President Bill Zahner.