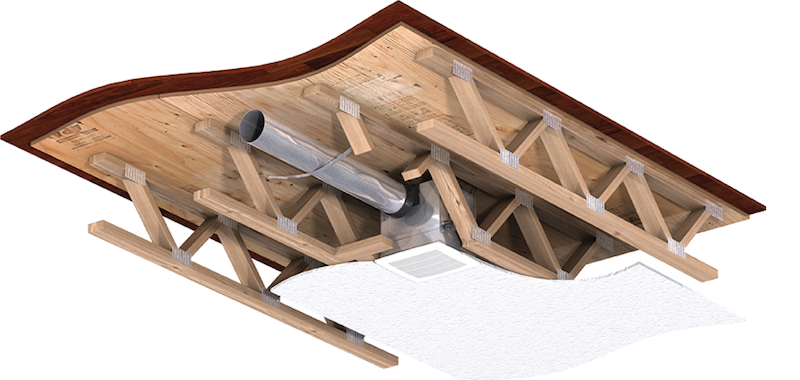

Bathroom exhaust fans are the most common way to properly ventilate and control moisture in residential bathrooms. Along with providing effective ventilation, bath fans with a ceiling radiation damper (CRD) are one of many components used to mitigate the spread of fire in many multifamily residential buildings such as apartments, assisted living and hotels.

In the event of a fire, the obvious goal is to extinguish it as quickly as possible while containing it to prevent the spread to adjacent units.

Picture a typical drywall ceiling in a bathroom. When the ceiling is cut to install a bath fan, the ceiling is essentially de-rated by removing the fire protective barrier. A ceiling radiation damper often is required by code to be paired with the bath fan to re-establish a fire barrier. In the event of a fire, a fusible link will melt, and close the damper to prevent the fire and smoke from spreading through the penetration created by the fan.

CRD requirements vary by jurisdiction and are most often necessary when structures are built of combustible materials like wood. While the requirements may vary, most jurisdictions rely on independent certifying organizations to provide direction. The most common and robust certification on the market for a CRD is UL 263-1 Hour Combustible Floor/Ceiling Assembly.

CONSIDER THESE BEST PRACTICES WHEN SPECIFYING EXHAUST FANS

If a bath fan requires a ceiling radiation damper based on building type and location, the specifying engineer has a few options. The engineer may call out the desired manufacturer and UL Design Number, or just the UL Design Number.

The specifying engineer must understand this process so as to not inadvertently limit the number of manufacturers who can be used. For example, many specific UL Design numbers are proprietary to the manufacturer that sponsored the test set up. These not only are proprietary, but each design is usually exclusive to a given manufacturer.

The specifying engineer has more flexibility to consider specifying multiple floor/ceiling design numbers or to specify designs that are open (not exclusive to a single manufacturer). This approach allows bids from multiple manufacturers. Open design numbers would allow any manufacturer that meets UL 263 to be eligible.

FASTENING: THE BENEFITS OF USING A FACTORY-INSTALLED SYSTEM

If using ceiling radiation dampers that are shipped loose from the fan and require assembly on site, it is important to review the specific requirements for the fastener type and quantity per each of the four sides before installation. Since most bath fan manufacturers only offer ship-loose CRDs, the potential for damage, loss, or improper attachment exists.

The best way to prevent any problems related to this is by selecting bath fans with factory-installed CRDs. A factory-mounted CRD will save time in the field.

Assume it takes about 5-10 minutes to install a CRD to a bath fan when assembling on site. Consider the labor savings on a 500-unit multifamily structure. Choosing a bath fan with factory-mounted CRD could potentially save thousands of dollars in field labor.

NOT ALL INSTALLATIONS ARE CREATED EQUAL

Next, evaluate the installation steps required for a specific fan and CRD. Review each bath fan manufacturer’s specific installation requirements to ensure compliance with any processes in addition to standard compliance.

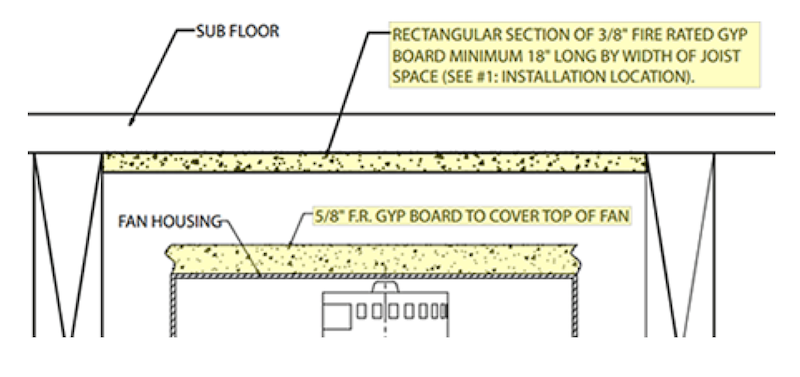

For example, most manufacturers require the installation of an additional damper mounting frame. However, some manufacturers have additional requirements, such as a contractor-provided section of drywall installed on top of the fan housing and beneath the subfloor (see figure). This last step will add extra time and cost during installation.

Some manufacturers require an additional piece of drywall be used to cover the top of the fan.

The fan and CRD assembly will not meet the certification requirements if the installer does not follow the stated installation steps. An inspection may reveal that the fan and CRDs may need to be removed and replaced if installed improperly. This scenario will add significantly more cost and labor time to the project.

A proper understanding of the purpose of a CRD, a proper specification, and a review of the installation requirements will help make the entire process much easier for the engineer and building contractor.

Learn more about ceiling radiation dampers and ceiling exhaust fans that come installed from the factory to save time and cost.

For more information, contact: freshairblog@greenheck.com.

ABOUT THE EXPERT

Craig Kuski is an Application Engineering Specialist in the ceiling exhaust fan unit of exhaust fan manufacturer Greenheck.